Batch Culture Definition

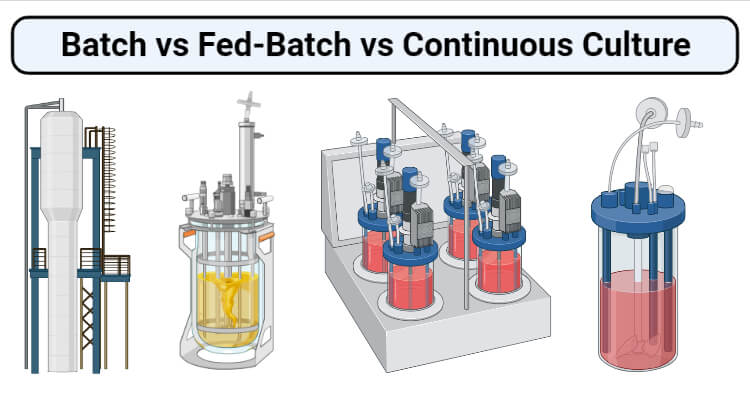

In batch culture, all the medium components are placed in the reactor at the start of cultivation except for atmospheric gases, acid or base for pH control, and antifoaming agents.

There is a continuous change in the nutrient concentrations over time, and the system remains unsteady.

Fed-Batch Culture Definition

In simple words, fed-batch culture is a modification to batch fermentation. In fed-batch cultivation, nutrients are added aseptically; it is a semi-open system, and the volume of liquid culture in the bioreactor increases as the culture is systematically added. A fed-batch culture is more productive, yields better with controlled sequential additions of nutrients, enables higher cell densities, and prolongs product synthesis.

Continuous Culture Definition

Continuous culture is a continuous process where nutrients are continually added to the bioreactor and the culture broth (containing cells and metabolites) is removed at the same time. The volume of the culture broth is constant due to a constant feed-in and feed-out rate (i.e consumed nutrients are replaced and toxic metabolites are removed from the culture).

Interesting Science Videos

Batch vs Fed-Batch vs Continuous Culture (20 Major Differences)

| S.N | Batch culture | Fed-batch culture | Continuous culture |

| 1 | In batch fermentation, all the medium components are placed in the reactor at the start of cultivation. | A fed-batch culture is a modification to batch fermentation in which nutrients are systematically added. | Continuous culture is a continuous process where nutrients are continually added to the bioreactor and the culture broth (containing cells and metabolites) is removed at the same time. |

| 2 | Fermentation is carried out in a closed system. | Fermentation is carried out in a semi-closed system. | Fermentation is carried out in an open system. |

| 3 | It is a discontinuous process. | It is a semi-continuous process | It is a continuous process. |

| 4 | The nutrients are all supplied at the beginning of cultivation, without further additions later on. | The nutrients are supplied at the beginning and later on added systematically during the process of cultivation. | The nutrients are added continuously throughout the process of cultivation and the product formed is continuously taken out. |

| 5 | When the products are formed, the whole process is halted | When the products are formed, the whole process is halted | The process continues, and the products are constantly removed from the fermentor. |

| 6 | Microorganisms go through four-phase

|

Microorganisms go through four-phase

|

Microorganisms are maintained at lag and log phases throughout the process. |

| 7 | The internal environment doesn’t remain constant. | The internal environment remains constant. | The internal environment remains constant. |

| 8 | The volume of nutrients remains the same. | The volume of nutrients increases. | The volume of nutrients remains the same. |

| 9 | The fermentation setup is not altered once the process is underway | When the fermentation process begins, the environment is changed from outside | When the fermentation process begins, the environment is changed from outside |

| 10 | Since nutrients and other conditions are limited inside, the turnover rate is low. | Since the optimal levels of nutrients are being maintained, the turnover rate is medium. | Since the optimal levels of nutrients and other conditions are being maintained, the turnover rate is high |

| 11 | There is no chance of contamination and mutation. | There is a chance of contamination and mutation. | There is a chance of contamination and mutation. |

| 12 | During the process, there is less control over microbial growth and desired product. | During the process, there is more control over microbial growth and desired product. | During the process, there is more control over the microbial growth and desired product. |

| 13 | Batch cultures are performed in large fermentors | Fed-batch cultures are performed in small fermentors | Continuous cultures are performed in small fermenters. |

| 14 | Batch culture setup is simple to set up and run. | Fed-batch culture setup is complex and difficult to implement and maintain | Continuous culture setup is complex and difficult to implement and maintain. |

| 15 | Product yield is low | Product yield is high. | Product yield is high |

| 16 | Labor demand is less | Labor demand is high. | Labor demand is high. |

| 17 | Less investment required | High investment is required | High investment is required. |

| 18 | Control methods are easy and quick | Control methods are complex and time-consuming | Control methods are complex and time-consuming |

| 19 | It is mainly used for the production of secondary products such as antibiotics. | It is mainly used for the production of alcohol and recombinant proteins. | It is mainly used for the production of primary metabolites such as amino acids and organic acids. |

| 20 | The product is harvested by a downstream process. | The product is harvested by a downstream process. | Downstream processing is complicated. |

References

- Avili, M. G., Fazaelipoor, M. H., Jafari, A., & Ataei, S. A. (2012). Comparison between batch and fed-batch production of rhamnolipid by Pseudomonas aeruginosa.

- Blaby, I. K. (2011). Modes of Culture / Microbial. In Comprehensive Biotechnology (Second Edition, Vol. 1 Elsevier B.V. https://doi.org/10.1016/B978-0-08-088504-9.00034-9

- Crueger, W., Crueger, A., & Aneja, K. R. (2017). Crueger’s biotechnology: A textbook of Industrial microbiology. MedTech.

- Ghosh, B., Bhattacharya, D., & Mukhopadhyay, M. (2018). Use of Fermentation Technology for Value-Added Industrial Research. Principles and Applications of Fermentation Technology, August, 141–161. https://doi.org/10.1002/9781119460381.ch8.

- Kuila. A, Sharma. V (2018). In Principles and Applications of Fermentation Technology. https://doi.org/10.1002/9781119460381.

- Najafpour, G. D. (2015). Biochemical engineering and biotechnology. Elsevier. https://doi.org/10.1016/B978-044452845-2/50005-7.

- Srivastava, A. K. (2011). 2.38 – Fed-Batch Fermentation – Design Strategies. Comprehensive Biotechnology, 1, 515–526. https://doi.org/10.1016/B978-0-08-088504-9.00112-4

- Yang, Y., & Sha, M. (2017). A Beginner’s Guide to Bioprocess Modes-Batch, Fed-Batch, and Continuous Fermentation.