Interesting Science Videos

Fed-batch culture Definition

In simple words, fed-batch culture is a modification to batch fermentation. In fed-batch cultivation, nutrients are added aseptically; it is a semi-open system, and the volume of liquid culture in the bioreactor increases as the culture is systematically added. A fed-batch culture is more productive, yields better with controlled sequential additions of nutrients, enables higher cell densities, and prolongs product synthesis.

The main advantages of fed-batch over batch culture are:

- Long-term synthesis of products,

- By increasing the number of cells and thereby increasing the amount of product, which is proportional to the concentration of the biomass, greater efficiencies can be achieved in the process,

- Increasing yield and productivity with controlled sequential additions of nutrients,

- It allows the bioreactor to be used production for non-profitable periods when it would normally be prepared for the next batch.

In a fed-batch process, the broth does not generally need to be removed during the entire fermentation process, but the amount of limiting nutrients added determines the rate of reaction.

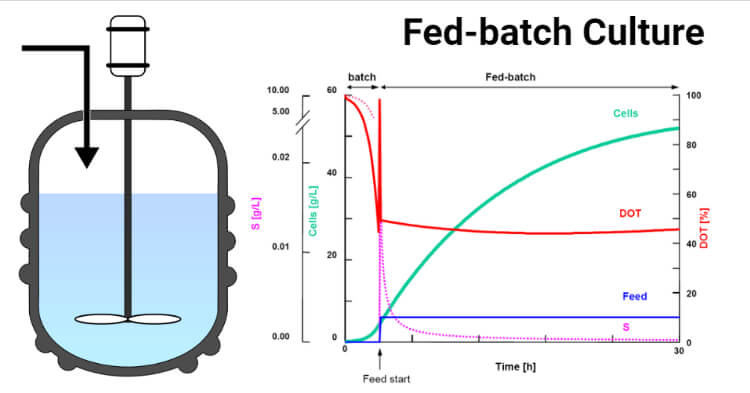

Figure: Fed-batch reactor symbol and The graph shows the principle of a substrate limited fed-batch cultivation with an initial batch phase. After consumption of the initial substrate, a continuous and constant feed of the substrate is started. Image Source: Wikipedia.

Fed-batch culture has the following mention advantages:

- Catabolite repression and Crabtree effects can be managed by limiting the substrate concentration.

- The high cell density of the cells could be achieved

- It is possible to increase the production of non-growth-related metabolites.

- When necessary, the broth viscosity can be reduced.

- It allows the replacement of water loss, by evaporation.

Principle of Fed-batch culture

- The initial process is similar to batch culture, all of the substrates are added at the beginning of the fermentation.

- The culture broth is harvested usually only at the end of the operational period, either fully or partially (the remainder serving as the inoculum for the next repeated run)

- In the fed-batch culture, a substrate is added in increments as the fermentation progresses.

- These substrates are added in small concentrations during the production phase.

- In the course of operation, there are one or more feed streams but no effluent.

- To control the feeding process, many indirect parameters that are related to the metabolism of a substrate are measured since it is not possible to measure the substrate concentration directly and continuously.

- Therefore, the culture volume increases during the course of operation until the volume is full.

Process of Fed-batch culture

- The process will be initiated with batch fermentation and consume substrate, nutrients, and/or inducers.

- Fresh medium will be added through a variety of feed streams.

- The microorganisms are inoculated and grown using a batch process for a set period, then nutrients are added to the fermenter in increments throughout the rest of the fermentation.

- By manipulating the feed rates during the run, carbon, nitrogen, phosphates, nutrients, precursors, or inducers are added intermittently or continuously to the culture.

- The common feeding strategies are:

- discontinuous feeding, achieved by regular or irregular pulses of substrates and

- regular continuous feeding of nutrients designed according to pre-calculated data or based on the feedback control of online measured variables associated with cell growth and metabolism

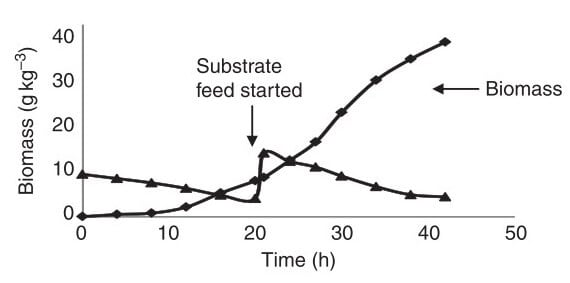

- As a result of the addition of fresh nutrients, extensive biomass accumulation normally occurs during exponential growth.

- Fed-batch fermentation is therefore very useful for bioprocesses that aim for high biomass density or high product yield when the desired product is positively correlated with microbial growth.

- The growth rate can be controlled by the substrate concentration to avoid catabolite repression.

- The products are harvested only at the end of the run.

- The culture volume increases during the course of operation until the volume is full.

- Thereafter, a batch mode of operation is used to attain the final results.

Types of Fed-batch culture

1. Fixed-Volume Fed-Batch Culture

- This procedure involves feeding the limiting substrate to the reactor very concentrated so that there is no notable increase in volume.

- To achieve an almost constant culture volume, the growth-limiting substrate must be fed in a form of concentrated liquid or gas, in purified form by dialysis, or by way of radiation sterilization.

- A constant-volume fed-batch system has been used for hyperthermophilic Archaebacteria cultivated under aerobic conditions.

2. Variable-Volume Fed-Batch Culture

- It is a type of fed-batch fermentation that involves the addition of substrate feed that changes working volume with the fermentation time.

- The volume change can be influenced by process requirements, time availability, and the objective of the fermentation process.

- In the variable-volume fed-batch process, the feeding strategy can be decided based on options such as the following

- For batch processing, a similar medium composition could be used.

- As required, only the limiting substrate, at a concentration similar to that used for batch processing, may be added as per the need and desire, while the rest of the medium constituents can then be added at the beginning at the same rate as the total reactor volume.

- The limited substrate, in a concentrated form, could be added at a slow rate to prevent excessive dilution of the fermentation broth

3. Repeated or cyclic fed-batch culture

- During this process, when the fermentation reaches the stationary phase and there are no significant changes in the growth of the cells (either due to substrate depletion or product inhibition), a certain amount of spent broth from the fermenter is removed, followed by the addition of fresh nutrient medium.

- With this removal and addition, the substrate concentration increases in the fermenter, which results in an increased specific growth rate.

- However, the specific growth rate again decreases as the substrate is consumed and a quasi-steady state is attained.

- Repeated fed-batch cultivation was used to optimize conditions for penicillin G biosynthesis by the use of a phosphorous feeding strategy.

4. Single fed-batch process

- In single fed-batch culture, the feeding solution is added during the fermentation process, but spent broth is not removed.

- In contrast, the major disadvantage of this method is that a lot of the fermentation broth is not utilized until the end of the fed-batch process.

- Thus, reactor volume can be a serious limiting factor for the duration of the fermentation.

Application of fed-batch culture

Various products produced or attempted to be produced by fed-batch techniques

| Product | Example |

| Amino Acids | Glutamic Acid, Lysine, Tyrosine, Tryptophan, Alanine |

| Antibiotics | Candidin and candihexin;

Cephalosporin C, Chlorotetracycline, Griseofulvin, Penicillin, Streptomycin, Tetracycline, Baker’s yeasts |

| Enzymes | Cellulase, Galactosidase, Isoamylase, Protease, β–amylase, α–amylase, β–Galactosidase, β–Glucanase, β–Glucosidase |

| Solvents | Acetone, Butanol, Glycerol, 1,3-Propanediol |

| Vitamins | Riboflavin, Vitamin B12 |

| Microbial Cell Mass

Bacteria Yeasts |

Cellulomonas sp., PseudomonasCandida boidinii, Candida utilis, Pichia farinose, Saccharomyces cerevisiae |

| Animal Cell Culture | Non-GS NS0 cell line, Hybridoma |

| Others | Acetic acid, Citric acid, Gibberellic acid, Neutral lipids, Polyhydroxyalkanoate (PHA), Dihydroxyacetone (DHA), Human interferon-γ, Clavulanic acid, Poly-β-hydroxybutyrate (PHB) |

Limitations of Fed-batch culture

- The microbe needs to be analyzed before its cultivation to determine its requirements, its physiology, and its productivity.

- To set up fermentation and develop the process, considerable operator skill is required.

- A cyclic fed-batch culture should be designed with care to ensure that toxins are not accumulated to inhibitory levels and that nutrients other than those incorporated into the fed medium are not limited if many cycles are run.

- Higher costs in labor and/or dynamic process control for the process.

- The quantities of components to control must be above the detection limits of the available measuring equipment.

References

- Blaby, I. K. (2011). Modes of Culture / Microbial. In Comprehensive Biotechnology (Second Edi, Vol. 1). Elsevier B.V. https://doi.org/10.1016/B978-0-08-088504-9.00034-9

- Crueger, W., Crueger, A., & Aneja, K. R. (2017). Crueger’s biotechnology: A textbook of Industrial microbiology. MedTech.

- EL Moslamy, S. H. (2019). Application of Fed-Batch Fermentation Modes for Industrial Bioprocess Development of Microbial Behaviour OPEN ACCESS.

- Kuila. A, Sharma. V (2018). In Principles and Applications of Fermentation Technology. https://doi.org/10.1002/9781119460381

- Saarela, U., & Juuso, E. (2003). Modelling of a Fed-Batch Fermentation Process Ulla Saarela , Kauko Leiviskä and Esko Juuso Report A No . 21 , June 2003. January.

- Saran, S., Malaviya, A., & Chaubey, A. (2019). Introduction, Scope, and Significance of Fermentation Technology.Ch1. 1, 1–25.

- Srivastava, A. K. (2011). 2.38 – Fed-Batch Fermentation – Design Strategies. Comprehensive Biotechnology, 1, 515–526. https://doi.org/10.1016/B978-0-08-088504-9.00112-4

- Yang, Y. (2017). Application Note No.408: A Beginner’s Guide to Bioprocess Modes – Batch, Fed-Batch, and Continuous Fermentation. Eppendorf Inc., 408.

Good notes

Very helpfull notes..☺️