Extending the shelf life of food without disturbing its natural quality is a great concern in food technology. Ozone treatment is a possible alternative for food preservation as it has quick decomposition properties with little residual effect.

- Ozone is triatomic oxygen (O3) with strong oxidizing power and can inactivate microorganisms effectively.

- It is a very reactive form of oxygen.

- It is also termed as a “natural disinfectant”.

- U.S. FDA accepted it as a GRAS substance for water treatment in 1982 and food in 1997.

- Ozone use for water treatment is the best alternative to replace chemical treatment like chlorination.

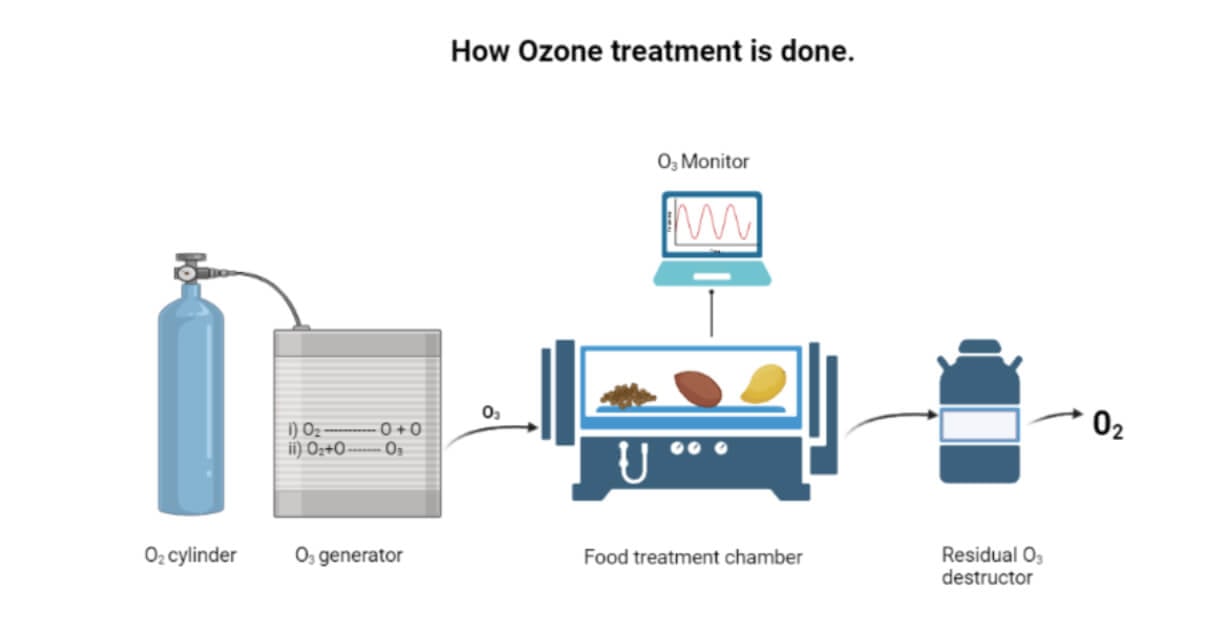

- Ozone generators are used to produce ozone at safe concentrations; for commercial production, it is generated by corona discharge.

- During ozone production, O2 breaks into highly reactive singlet oxygen, and this singlet oxygen interacts with additional O2 to form ozone (O3).

Interesting Science Videos

Forms of Ozone

- Gaseous ozone

- Ozone in gaseous form

- It is used for storage treatment

e.g., the use of Gaseous ozone to decontaminate the eggshell which reduces the risk of spoilage of egg, and use to preserve spices, grains, beans, etc

- Aqueous ozone

- Ozone that is incorporated into the water in bubble form

- It is used as a surface disinfectant

e.g., to reduce the microbial load of fish fillets

Properties of ozone

- Very reactive

- Gaseous ozone is soluble in water

- More stable at lower temperatures (4 – 120c)

- More stable at pH 5.0 and unstable at high pH

- The stability and effectiveness of ozone depend upon organic and inorganic materials present in food

Process of Formation of Ozone

Addition of a free radical of oxygen to molecular oxygen

- High voltage alternating current splits oxygen molecules into atoms

- Atoms of oxygen then combine with other oxygen molecules and form ozone (O3)

Mode of action of food treatment

- Destruct lipids, protein, nucleic acid, and other cellular components due to oxidative reactions

- Protein degradation and cellular structure modification

- Damage spore inner membrane due to oxidization

Application of Ozone Treatment

- To disinfect production areas, plant equipment, and surfaces from microorganisms

- Effective to kill spores of Bacillus and Clostridium species.

- Inhibit fungal growth in fruits and vegetables

- Gaseous ozone helps to decontaminate eggshell

- Reduce the level of natural microbiota in fish products

- Reduce microbial load in spices, grains, beans, etc.

Advantages of Ozone Treatment

- High antimicrobial activity as it is 3000 times faster than chlorine at killing microorganisms

- Fast decomposition to simple oxygen

- No waste generation

- Lower energy input as compared to other thermal and non-thermal techniques.

- Eco-friendly and economically feasible

Disadvantages of Ozone Treatment

- High ozone concentrations can be hazardous.

- Cause throat and nasal problems if inhaled by us.

- It decomposes quickly, so it cannot be stored.

- Ozone can react with proteins and fats in carcass treatment before inactivating microorganisms.

References

- Potter NP (1987), Food Science, CBS Pub, India.

- Rahman MS (1999), Handbook of Food Preservation, Marcel Dekker, Inc, NY.

- Desrosier EN (1963), The Technology of Food Preservation, AVI Publishing Company, New York.

- Sarron E, Gadonna-Widehem P, Aussenac T. Ozone Treatments for Preserving Fresh Vegetables Quality: A Critical Review. Foods. 2021 Mar 12;10(3):605. doi: 10.3390/foods10030605. PMID: 33809297; PMCID: PMC8000956.

- R. Pandiselvam, S. Subhashini, E.P. Banuu Priya, Anjineyulu Kothakota, S.V. Ramesh & S. Shahir (2019) Ozone based food preservation: a promising green technology for enhanced food safety, Ozone: Science & Engineering, 41:1, 17-34, DOI: 10.1080/01919512.2018.1490636.