An incinerator is a furnace intended for burning dangerous items in a combustion chamber, where incineration is carried out.

Burning potentially dangerous materials at temperatures high enough to eliminate pollutants is known as incineration. Incineration is most commonly used where there is a large-scale accumulation of waste and when treating bulky heterogeneous waste needs treatment. It can treat various hazardous pollutants, including soil, sludge, liquids, and gases. In contrast to the inorganic content of trash, which helps to generate ash, the organic portion of garbage gets burned and produces heat. Ash, heat, and combustion gases are the final byproducts of incineration. Although incineration eliminates various dangerous substances, including solvents, PCBs (polychlorinated biphenyls), and pesticides, it does not eliminate metals like lead and chromium.

Solid, liquid, and gaseous waste from manufacturing processes is safely disposed of using incinerators. Through the use of auxiliary machinery like steam boilers, they can be used to generate electricity by heat or steam flow. To lessen their detrimental effects on the environment, modern incinerators use air pollution control technology.

Interesting Science Videos

Principle of Incinerator

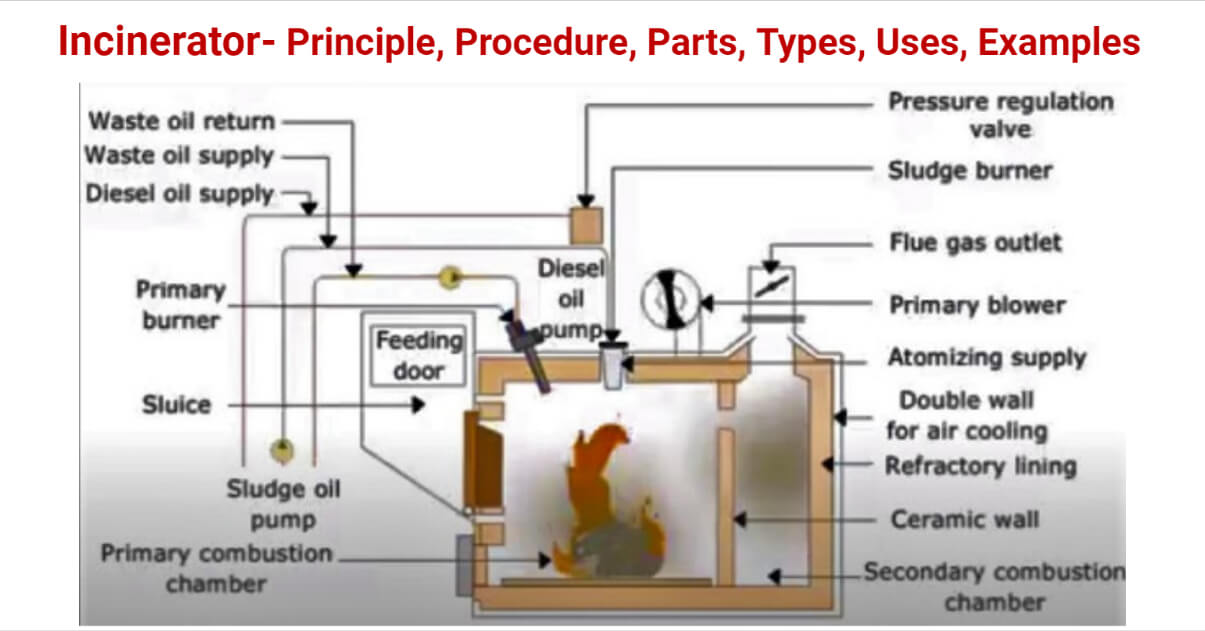

A primary combustion chamber for burning solid waste or sludge oil is included in the design of the incinerator. In contrast, a secondary combustion chamber is included for burning out any unburned exhaust gases. A primary burner is installed in the primary combustion chamber. This burner receives diesel oil to ignite it initially. After that, the primary burner receives the sludge oil until it ignites, manually or automatically turned off. The sludge burner receives atomizing air to facilitate effective combustion. On the sludge return line, there is a pressure-regulating valve that can be used to control the amount of sludge that enters the conversion chamber. The solid waste will dry out and begin burning when the primary burner’s heat is applied, and the sludge oil may also catch fire. The gases from the primary combustion chamber will burn out in the secondary combustion chamber. The primary and secondary combustion chambers are divided by a wall of ceramic heavy-duty refractory liners. Solid waste is fed into the incinerator through the feeding door in cases of solid waste or garbage. The primary burner cannot be lit if this door is open, but the rest of the combustion process continues as usual.

Operating procedure of Incinerator

- The primary combustion chamber of the incinerator is intended for burning solid waste or sludge oil, while the secondary combustion chamber is intended for burning off any unburned exhaust fumes. A primary burner is installed in the primary combustion chamber, which receives diesel oil to ignite it initially. After that, the primary burner receives the sludge oil until it ignites.

- The primary burner is then turned off manually or automatically.

- For effective combustion, the sludge burner receives atomizing air.

- To control the amount of sludge entering the conversion space, a pressure-regulating valve is supplied on the sludge return line.

- The primary burner’s heat will cause the solid waste to dry out and begin burning, as well as ignite the sludge oil.

- The primary combustion chamber’s enormous transmission area optimizes the solid waste’s drying and burning.

- The primary combustion chamber’s gases will burn out in the secondary combustion chamber. The primary and secondary combustion chambers are separated by a wall of ceramic heavy-duty refractory liners.

- Solid waste is fed into the incinerator through the feeding door when it is solid garbage or waste.

- The primary burner cannot be lit if this door is open, but the rest of the combustion process continues as usual.

Parts of Incinerator

The common parts of the incinerator are as follows:

Primary chamber: All garbage will be fed into the primary chamber and burned for the first time there. The primary chamber is where the waste vapourises. The low air-to-fuel ratio in this starved-air chamber causes the waste to dry out and makes it easier for it to evaporate, burning up most of the carbon.

Secondary chamber: Waste-derived volatile/gasified substances are transferred to the secondary chamber. To complete combustion, more air is injected in the second stage into the volatile gases created in the initial chamber. Temperatures in the secondary chamber are higher than those in the primary chamber. Due to the appropriate residence time, high temperature, and 100% surplus air in the secondary chamber, the gaseous products (volatile material) are oxidized. The gases are handled after they exit the secondary chamber.

Finally, the gases are introduced to the droplet separator, where the moisture is taken out of the gases. This lowers the temperature of the flue gas, making it safe to release into the atmosphere.

Flue Stack: The term “chimney” also applies to the flue stack. Stack height requirements for most incinerators are 3 meters or greater. In more populated places or where the atmosphere requires it, this requirement will be greater.

Control panel and thermocouples: These regulate the machine’s operation and guarantee that the chambers are heated up before any waste is loaded for incineration. Depending on the type of waste, the settings can be tailored to the operator’s needs.

Burners: These are utilized to warm the incinerator up and are often turned off throughout the burning process.

Fuel tanks: The fuel is kept in storage. During the operation of the incinerator, the burners will have direct lines into the tank.

Types of Incinerator

In commercial use, there are different categories of combustion technologies:

- Rotary Kiln Incinerator

- Fluidized Bed Incinerator

- Moving Grate Incinerator

- Multiple Hearth Incinerator

- Liquid injection Incinerator

- Catalytic combustion chamber

- Waste gas flare incinerator

- Fixed Grate Incinerator

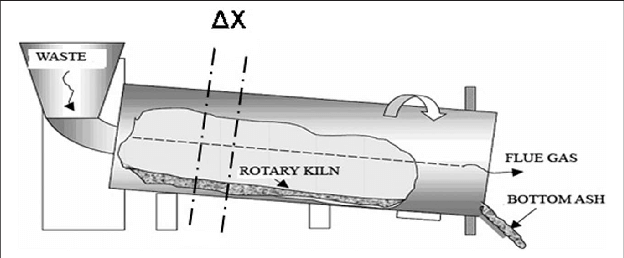

1. Rotary Kiln Incinerator

The basic design consists of two thermal treatment chambers: a primary chamber that is slightly slanted and into which waste is fed (along with hot exhaust air containing oxygen), rotated, and thermally decomposed by heat radiation from the secondary chamber; and a recombustion chamber that is located at the back of the kiln and into which the decomposition air and the remaining waste is completely burned with the supply of secondary air. It is built with a rotating combustion chamber that keeps the garbage circulating continually. The waste can vaporize, which makes burning easier. By modifying the inclination angle and rotational rate of the kiln, the waste throughput rate can be managed. Solids burnout rates and particulate entrapment in the flue gas are higher for rotary kiln incinerators than for other incinerator designs due to the waste’s turbulent motion in the primary chambers. Because of this, gas cleaning accessories are frequently added to rotary kiln incinerators.

The advantages of rotary kilns include less NOx production and heat elimination of dangerous compounds.

In a rotary kiln incinerator, typical waste types that can be treated include Pharmaceutical waste, Hazardous waste, and Medical waste, such as sharps, infectious waste, surgical trash, clinical waste, laboratory waste, etc.

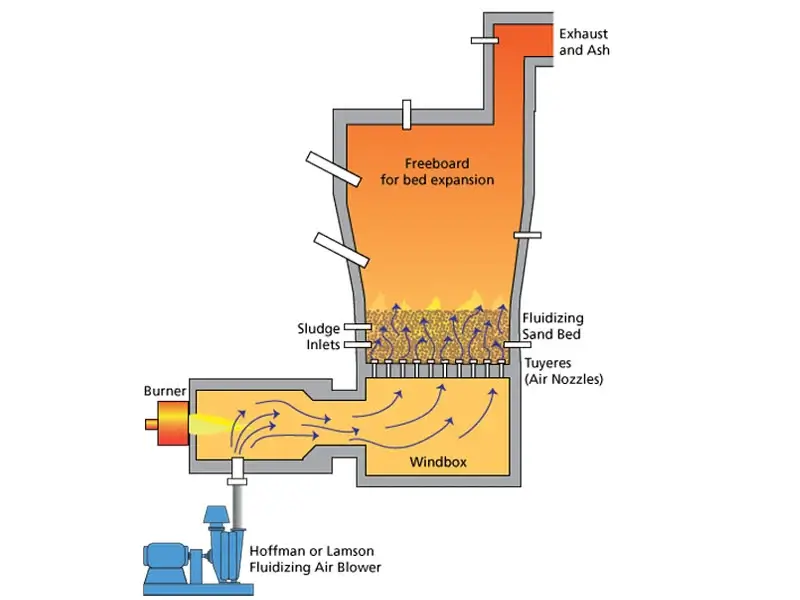

2. Fluidized Bed Incinerator

The process by which a fluid is passed through granular material in a solid state to change it into a fluid-like state is known as the principle of fluidization. The reactor typically comprises a vertical steel vessel lined with refractory material and a bed of granular material, such as limestone, silica sand, or ceramic material.

Air is injected into the bed through several nozzles at the bottom of the incinerator to keep it fluid. This results in a violent agitation of the bed material where the burning of trash takes place in close contact with the bed material and combustion air. Because of the comparatively low extra air level made possible by this, a high thermal efficiency of up to 90% is possible.

These are employed in the incineration of sewage sludge and industrial waste and are primarily used for homogenous waste types, including liquid waste.

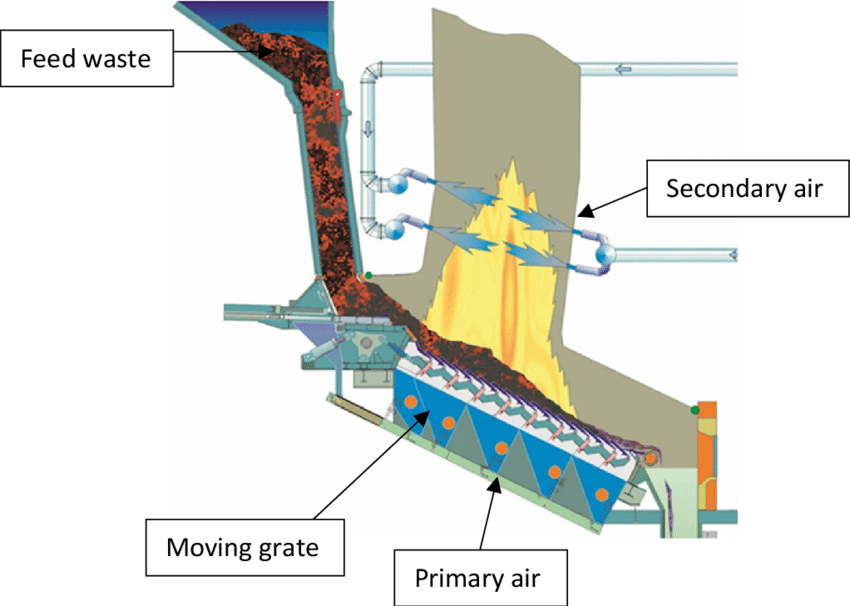

3. Moving Grate Incinerator

The waste is burned in layers on the grate that moves the waste through the furnace in a traditional mass-burning incinerator based on a moving grate. On the grate, the waste is dried before being burned at a high temperature with an air supply.

The non-combustible waste fractions, which include the ash, exit the grate through the ash chute as slag (bottom ash). The bottom ash (slag), which drops into the water trap of the slag pusher from the grate’s end, is then cooled by coming into contact with cooling water before moving on to the conveyor system. Typically, 10 to 25 percent of the weight of the waste feed is made up of slag.

The main benefits of the moving grate are its well-proven technology, ability to accept wide variations in waste composition and heat values, and ability to be produced in extremely large units. The primary drawback is the expense, which is relatively significant for investment and maintenance.

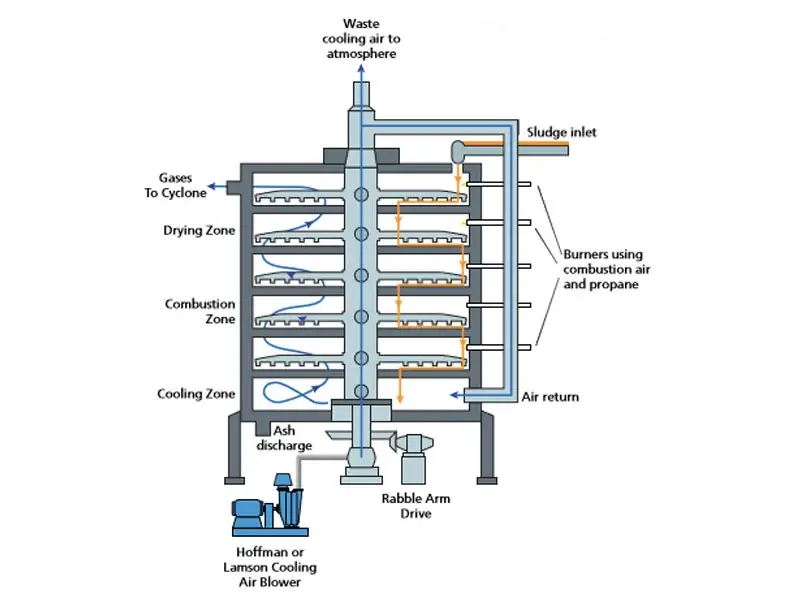

4. Multiple Hearth Incinerator

A multiple hearth incinerator consists of a row of circular hearths arranged in a column and protected by a steel shell lined with refractory with operating temperatures ranging from 1400 to 1800°F. The feed material is moved across each hearth in a spiral pattern by rabble arms attached to a vertical rotating shaft that runs through the furnace’s center before dropping through the openings into the hearth below. The finished product is ejected through an outlet after traversing through each hearth.

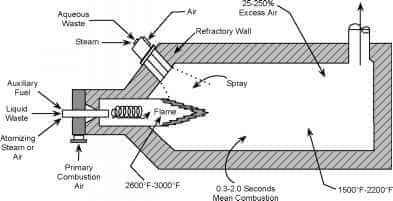

5. Liquid Injection Incinerator

A frequently used device that uses high pressure to split liquid wastes into tiny droplets for rapid burning. Wastes are delivered through nozzles and atomized into small droplets to enable the greatest possible mixing with air with operating temperatures ranging from 1200 to 3000°F. The feed must behave as a liquid with a viscosity of no more than 10,000 ssu. A solid can be used if it can be melted and pumped and can completely combust organic combustible material and non-combustibles like impurities in water.

6. Catalytic combustion chamber

In the 1970s, Engelhard Corp. discovered the procedure. It is a chemical process that uses a catalyst to accelerate the desired oxidation reactions of fuel and limit the creation of undesirable products, especially polluting nitrogen oxide emissions (NOx), well below what is possible without catalysts. It is intended specifically for low organic concentration waste.

7. Waste-Gas Flare Incinerator

In many industrial activities, including oil-gas extraction, refineries, chemical plants, the coal industry, and landfills, undesirable or excess gases and liquids are discharged. Gas flaring is a combustion device used to burn these gases and liquids. A substantial source of greenhouse gas emissions is gas flaring. Additionally, it produces heat and noise and renders a lot of space uninhabitable. It is used for non-hazardous waste with high organic content.

8. Fixed Grate/ Direct-Flame Incinerator

It is often the most widely produced and utilized. Fuel and oxygen are used to maintain the direct flame, allowing trash to be burned. When waste gas contains particles, direct flame incinerators are employed. They run between 1000 and 1500 °F.

Applications of Incinerator

Medical waste

Medical wastes generated from laboratories, hospitals, and health clinics can pose health risks if not properly treated or disposed of. Incinerators are designed to destroy and neutralize medical waste.

Animal waste

Incinerators are employed to dispose of animal wastes, including carcasses, waste, and byproducts, thereby preventing the spread of infection and viruses.

General waste

General wastes include less harmful wastes from sites such as mining, small communities, and military operations, which must be destroyed to reduce environmental impact. Thus, incinerators are devised to incinerate such wastes.

Nanomaterial wastes

Incinerators are utilized to dispose of nanomaterial wastes such as consumer products in municipal solid waste, wastes from nanotechnology research and development, hazardous wastes, etc.

Advantages of Incinerator

- Incinerators can reduce the total amount of garbage by up to 95% and the solid portion of the original waste by up to 80–85%.

- Waste management can be facilitated and improved upon significantly through incineration. Landfills only permit organic breakdown, while non-organic waste continues to build up.

- Waste is converted into energy in incinerators, which can be utilized to produce heat or power.

- Compared to landfills, solid waste incinerators are less likely to contaminate the environment.

- Waste incineration facilities can be located close to cities or towns because they require less space. This has the advantage of reducing the need for long drives to dump waste.

- Waste is burned inside a facility where the byproducts of the incineration process can be regulated. Therefore, waste incineration plants generate a less unpleasant odor than landfills. This is because open-air degradation of waste, which adds to air pollution, is avoided.

- Waste incineration facilities are safer and better for the environment because they don’t emit methane.

- Incineration facilities burn processed waste at extremely high temperatures, killing hazardous bacteria and chemicals.

- Since incinerators burn waste without leaks, they are not restricted by variations in the weather.

Limitations of Incinerator

- An incinerator plant’s construction requires expensive infrastructure and equipment, which drives up the cost of the installation procedure.

- Even though garbage incinerators emit far fewer pollutants than landfills do, they nonetheless have a considerable impact on pollution, especially in the vicinity.

- Communities with waste incinerators are more likely to experience long-term negative health effects like cancer, birth defects, reproductive dysfunction, neurological issues, and other conditions known to occur at very low exposures to many of the metals and pollutants released by incinerators.

- Operation and administration of incinerators demand expensive and highly experienced labor.

Precautions

- To avoid cross-contamination, scrapes, and punctures from sharps, use heavy-duty gloves and full-body aprons.

- Before burning, sorting the waste reduces operator handling time and lowers the danger of disease, infection, and damage. This can be accomplished by applying the medical waste color coding scheme.

- Operators must have PPE kits since the extremely high temperatures pose a serious risk to everyone involved.

- If long hours of labor are necessary, eye protection using the proper shade of safety glass may help to limit exposure to the eyes.

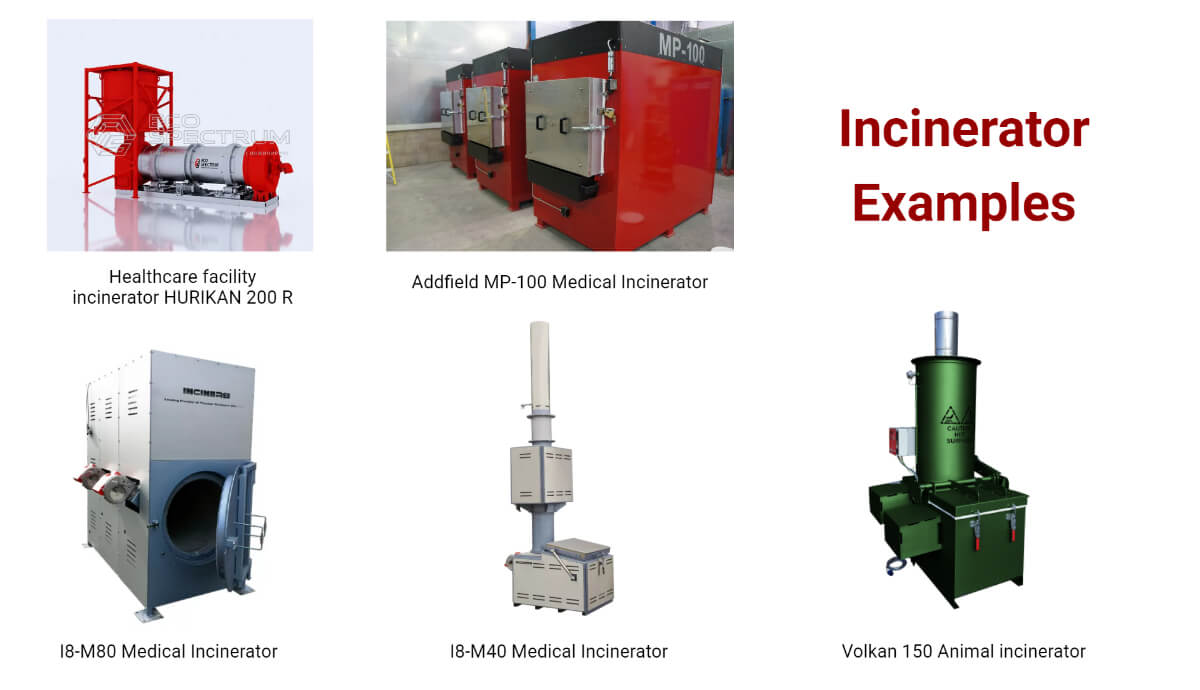

Incinerator Examples

1. Healthcare facility incinerator HURIKAN 200 R (Eco-Spectrum LLC)

- Contrary to brick linings, only the Eco-Spectrum firm employs special concrete monolithic linings in rotary incinerators, which assures the lack of technological gaps at the connecting points.

- Due to the ceramic plate (placed between the metal body of the furnace and concrete), the operation is allowed at high temperatures exceeding 850°C, which considerably reduces fuel consumption and avoids heating the drum furnace body from the outside.

2. Addfield MP-100 Medical Incinerator (Addfield Environmental Systems)

- A small to medium-sized medical incinerator that can safely eliminate various medical and clinical waste, including high moisture, pharmaceutical, and biological waste.

- The MP-100 is a small medical incinerator incorporating its secondary chamber within its thick steel outer shell. This, along with 180mm of advanced insulation, ensures that the MP-100 delivers excellent results while being completely safe to operate compared to inferior machines that lose heat during the process.

3. I8-M80 Medical Incinerator (Inciner8)

- The i8-M80 is a medium capacity specialist “M” incinerator for disposing medical waste. It has cylindrical combustion chambers, an integrated I.D. fan, and a clinical exterior design, making it the perfect choice for hospitals and medical waste collection facilities.

- It is self-contained and has a rear access door that can accommodate a built-in fuel tank and mounted control panel. The I8-M80 is delivered completely assembled, with a gasoline tank and plumbing included.

4. I8-M40 Medical Incinerator (Inciner8)

- The medical incinerator i8-M40 is easy to use and reliable. It was created for little medical institutions, dental offices, or other small clinics with minimal waste streams.

- The i8-M40 has a medium-capacity model. Increased insulation, an improved CE2-VFD control panel, and an I.D. fan enhance performance and provide all-around appropriateness for various medical, clinical, pharmaceutical, and hazardous waste streams.

5. Volkan 150 Animal incinerator (Eco-Spectrum LLC)

- The case of Volkan 150 Incinerator is constructed of high-carbon steel and has a minimum thickness of 4 to 5 mm. Along with steel components, the configuration determines the thickness and alloy of the steel.

- Due to insulating materials in a concrete-lined configuration, the VOLKAN 150 incinerator body cannot support thermal loads. The working surface that comes into contact with the burning waste is the combustion chamber’s lining.

- The heat-resistance layer of the paint and lacquer coating of the case improves the installation’s longevity when used outside of buildings and other structures.

References

- https://www.epa.gov/sites/default/files/2015-04/documents/a_citizens_guide_to_incineration.pdf

- https://www.marineengineersknowledge.com/2021/06/incinerator.html

- https://www.conserve-energy-future.com/advantages-and-disadvantages-incineration.php

- https://www.irjet.net/archives/V4/i12/IRJET-V4I1270.pdf

- https://www.inciner8.com/how-an-incinerator-works

- https://www.inciner8.com/blog/waste-management/what-are-incinerator-machines-an-idiots-guide

- https://slideplayer.com/slide/10814404/

- https://www.rpi.edu/dept/chem-eng/Biotech-Environ/incinerator.html

- https://www.medicalexpo.com/prod/addfield-environmental-systems/product-100393-652610.html

- https://www.medicalexpo.com/prod/inciner8/product-115640-876343.html

- https://www.medicalexpo.com/prod/inciner8/product-115640-796100.html

- https://www.medicalexpo.com/prod/eco-spectrum-llc/product-128354-1064290.html

- https://www.medicalexpo.com/prod/eco-spectrum-llc/product-128354-957625.html

- Lombardi, F., Lategano, E., Cordiner, S., & Torretta, V. (2013). Waste incineration in rotary kilns: a new simulation combustion tool to support design and technical change. Waste management & research: the journal of the International Solid Wastes and Public Cleansing Association, ISWA, 31(7), 739–750. https://doi.org/10.1177/0734242X13484187

- Bourtsalas, A.C., Huang, Q., Zhang, H., & Themelis, N.J. (2020). Energy recovery in China from solid wastes by the moving grate and circulating fluidized bed technologies. Waste Disposal & Sustainable Energy, 2, 27-36.

- https://frtr.gov/matrix2/health_safety/chapter_24.html

This article who define me incinerator is very use full and very easy to understand

Thank you…