Heat treatment or thermal treatment in food preservation can be defined as treating food at a high temperature for a specific period to kill or reduce the load of microorganisms that are meant to cause food spoilage.

The application of heat is very important in food preservation because of its preservative effects, like the destruction and inactivation of enzymes, toxins, microorganisms, etc.

It is also important in food processing as heat treatment helps to make food more tender and palatable and brings desirable effects (textures, colors, aromas, and flavors), which improves consumer choice.

Interesting Science Videos

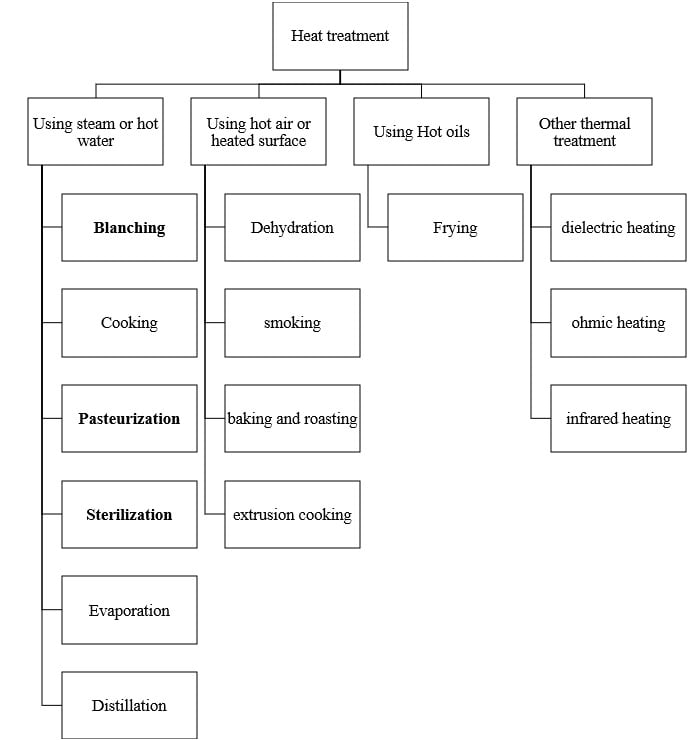

Different methods of heat treatment in food preservation

Role of heat treatment in food preservation:

- Inactivate enzymes

- Lower microbial load

- Destroy or inactivate spores and toxins

- Aids aroma, flavor, and texture of foods

- Make food more tender and palatable

- Aids in peeling

- Aids in packaging

Things to consider while choosing safe and proper heat preservation treatment

To get desired storage life and food products free from pathogens and toxins following must be known:

- Time and temperature combination to inactive the most heat-resistant pathogen.

- Food composition and heat penetration characteristics of the food matrix, along with the can or container of choice, should be known.

Advantages of heat treatment

- Simple and controlable

- Produce shelf-stable food and does not require refrigeration

- Destruction of anti-nutritional factors ANF ( tannins, phytates, oxalates, enzyme inhibitors)

- Improve the availability of nutrients

- Improve digestibility due to the breakdown of proteins, complex carbohydrates and

- Release bounded nutritional component

Disadvantages of heat treatment

- Quality loss: Excessive heat can destroy the organoleptic characteristics of food.

- Nutrient loss: Destroys some heat-sensitive vitamins and other nutritional factors

- Improper heat treatment can lead to the formation of other carcinogenic harmful compounds.

- Not effective for all microorganisms, as heat-resistant bacteria can grow

- Limited shelf-life

- Not applicable for heat-sensitive food

- Specialized types of equipment are expensive and consume more energy

The most common heat treatment methods in food preservation are :

- Blanching

- Pasteurization

- Heat Sterilization

1. Blanching

- ‘Blanching’ is a heat treatment process in food preservation in which vegetables and fruits are submerged in boiling water or steam to inactive enzymes and microorganisms, which can cause spoilage and nutrient loss.

- There are two types of blanching methods:

- Steam blanching

- Water blanching

- Microwave blanching

- Ohmic blanching

- Blanching is mostly used in food preservation as a pretreatment which is applied before other food preservation techniques like canning, freezing, drying, and other non-thermal techniques.

- During blanching, heat transfer occurs in two modes: convectively transferred from steam or hot water to the surface and conduction of heat from the surface to the interior of the food.

- Undesirable enzymatic, nutritional, and sensory changes and chances of reviving spoilage microorganisms in food products during storage can be eliminated with the application of blanching.

- Two heat-resistant enzymes, catalase, and peroxidase, are present in vegetables and are considered indicator enzymes to determine the success of the blanching process.

- The time and temperature used for the blanching process depend on the food type. Typical time-temperature combinations vary from 1 to 15 min at 80-100°C.

- Peroxidase/ catalase enzyme inactivation and retention of a specified proportion of vitamin C is the main concern in the blanching method.

Factors affecting blanching conditions

- Shape and size of food

- Thermal conductivity of food

- Blanching temperature and time

Advantages of blanching

- It helps to remove microorganisms from the vegetable surface and fruits skin

- Inactivation of enzymes- that may deteriorate food quality

- It helps in the peeling and dicing of raw food

- Improve color, texture, and flavor under optimum blanching temperature and time.

Defects of blanching on foods

- Blanching causes physical and metabolic changes within the food.

- Leaching losses: During blanching, heat makes the cell membrane permeable and allows water and solutes to pass into and out of the cells. During this, nutrients were lost from the fruits and vegetables being soluble in the hot water.

- Overblanching may lead to unfavorable softening, loss of sensory attributes, and cause discoloration of food products.

- Some minerals, water-soluble vitamins, and other components are lost during blanching. Typical vitamin losses are 15-20% for riboflavin, 10% for niacin and 10-30% for ascorbic acid, and >50% for folic acid

- Heat-sensitive vitamins like Vitamin B-1 are destroyed.

- Vitamin C losses are seen due to the exposure of tissues to the atmosphere.

Recent developments for blanching

- Microwave blanching; for mushrooms, turnip greens, and peanuts

- Ohmic blanching; for mushrooms, and peas, effective to destroy heat resistant enzyme peroxidase in a short period.

- Ultrasonic-assisted blanching

- High-humidity hot-air impingement blanching; for fuji apples and grapes.

- High-pressure blanching

2. Pasteurization

- Pasteurization in food preservation can be defined as the mild heat treatment used primarily to destroy pathogenic organisms and to inactivate enzymes present in low-acid/acidic food to extend their shelf-life.

- Pasteurization treatment can be applied either in a packaged container or unpackaged food products.

- Pasteurization is used to extend the shelf-life of food for several days (milk) or for several months (bottled fruit juice).

- Pasteruzation with a combination of other preservation methods like refrigeration and drying will be favorable to extend the shelf-life of products.

- Completion of pasteurization of milk can be confirmed by the Alkaline phosphatase (ALP) test.

- The degree of heat treatment required to pasteurize a food is determined by the acidic nature of the food and targeted heat-resistant enzymes or pathogens.

- In low acid-food like Milk, the degree of pasteurization is based on a 12D reduction in the number of pathogens ( Brucella abortis, Mycobacterium tuberculosis, and Coxiella burnetti).

Pasteurization conditions of different types of food and their specific purpose

The general purpose of pasteurization is to destroy pathogens, spoilage microorganisms, and to inactive enzymes.

| Type of Food | Specific Purpose | Pasteurization condition |

| Acidic Food (pH <4.5) | ||

| Fruit juice | Enzyme inactivation ( Pectinesterase, polygalacturonase) | 65°C for 30 min , 77°C for 1 min , 80°C for 10-60s |

| Beer | Destruction of wild yeasts, Lactobacillus spp., and residual Saccharomyces spp. | 65-68°C for 20 min, 72-75°C for 1 min ( in bottle) |

| Low-acidic food (pH>4.5) | ||

| Milk | Destruction of pathogens ( Brucella abortis, Mycobacterium tuberculosis, and Coxiella burnetti),Alkaline phosphatase enzyme | LTLT= 63°C for 30 min, HTST= 71.7°C for 15 s, 90°C for 0.5s |

| Ice cream | Destruction of pathogens | 69°C for 30 min, 71°C for 10min, 80°C for 25s |

| Cream or chocolate | Destruction of pathogens | 66°C for 30min, 75°C for 15s |

| Liquid egg | Destruction of pathogens (Salmonella) | 64.4°C for 2.5 min, 60°C for 3.5 min |

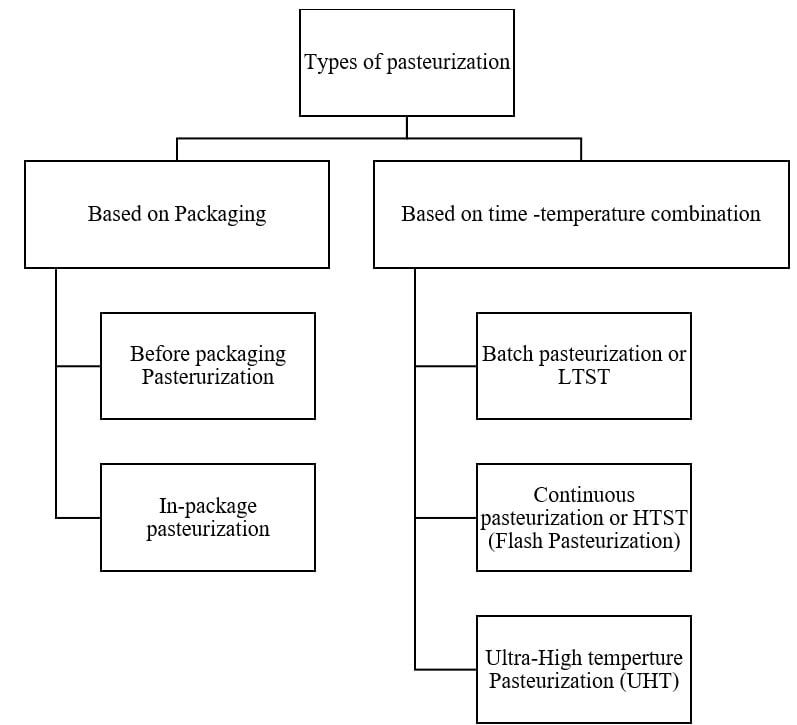

Types of pasteurization

- Before Packaging: Pasteurizing product first and then fill in a sterile container

- In-package pasteurization: first filling the product in a sterile container and then pasteurization

- Batch pasteurization or LTLT: The product is pasteurized by heating to 68°C. to 71°C. holding for 30 min

- Continous pasteurization or HTST (Flash Pasteurization): Heating product at a few higher temperatures than pasteurization temperature for a short time. E.g, in this method, fruit juice is heated rapidly for about 1 minute at a temperature 5°C. higher than the pasteurization temperature.

- Ultra-High temperature pasteurization or UHT: Operates at high temperature with a holding time in the order of 3 seconds.

Effect of pasteurization on foods

- Causes minor changes to most foods’ nutritional and organoleptic characteristics.

- Loss of volatile aroma compounds can be seen in fruit juices

- Losses of heat-labile vitamins like thiamin and vitamin c.

Things to be considered before or after pasteurization

- Loss of vitamin C, carotene, discoloration, or enzymatic browning of fruit juice can be prevented by deaeration before pasteurization.

- Milk should be homogenized before pasteurization

- Fruit juices are practiced to pasteurize twice, first at 95-98°C. for 10-30s to inactivate enzymes and pathogens and secondly, at 95°C. for 15s before filling in a container to avoid recontaminations.

- Carbonated juices and other high-acid juices can be pasteurized safely at 65°C., this temperature destroys most of the yeast cells.

- Non- carbonated juices must be pasteurized at 80°C.

- Pasteurized milk must be refrigerated following pasteurization to make it sterile.

- Pasteurization does not aim to kill spores

- Food should be immediately filled into bottles and sealed to prevent decontamination.

3. Heat Sterilization

- Food sterilization can be of two types; by heating (thermal process) and without heating (non-thermal process).

- The term “heat sterilization” refers to the destruction of vegetative microbial cells, spores, and inactivate enzymes by heating.

- Heat sterilization is an important unit operation in food preservation and processing technology.

- Sterilization destroys yeasts, molds, vegetative bacteria, and spore formers.

- In practice, Commercial sterilization is preferred as complete sterilization will deteriorate product quality and nutritional value.

- Commercial sterilization refers to the degree of sterilization at which all pathogenic and toxin-forming microorganisms have been destroyed. Some heat-resistant spores may remain in the product but will not normally multiply.

- Most of the canned and bottled food products are commercially sterile and have a shelf-life of more than 2 years.

- Destroying two types of bacteria; Clostridium botulinum and C. sporogenes is a great concern in food preservation.

Principle of sterilization

- Treated products must be free from spoilage microorganisms or toxins released from them.

- Heat treatment should be at least 121.1°C. for 3 minutes to achieve a 12D reduction of microorganisms and up to 15 minutes to destroy bacterial spores completely.

- Processing under the slowest heating point (cold point) with proper time and temperature combination will help to make the product sterilized.

Factors affecting the degree of heat sterilization

- Processing equipment design

- Type of heating media

- Shape and size of packaging container/can/bottle.

- pH and water activity of the food product

- Product composition and viscosity

- Targeted microorganisms, spores, or enzymes

Types of heat sterilization

- In-container sterilization (bulk canning)

- Aseptic sterilization (Processing)

a. In-container sterilization (canning)

- Canning is commercial sterilization that aims to destroy pathogenic microorganisms, inactivate enzymes and kill spoilage microorganisms to ensure the required shelf-life and required sensory and nutritional value of the product packaged in a hermetically sealed container.

- This technique can be used to preserve plant-origin and animal-origin foods.

Effect of canning on the quality of canned food

- Heat-induced Maillard reaction which affects color and flavor along with nutritional status

- Starch gelatinization and structural protein denaturation influence the texture of food

Steps of canning

- Selection and grading of foods

- Cleaning and blanching of foods

- Filling in tin can or bottle

- Addition of an appropriate amount of brines or sugar solution or other fillers.

- Lidding, exhausting, and sealing

- Sterilize food by heating with a proper time-temperature combination under pressure

- Cooling the product up to 38°C.

- Storing product at a temperature less than 35°C.

- Labelling

- Packaging

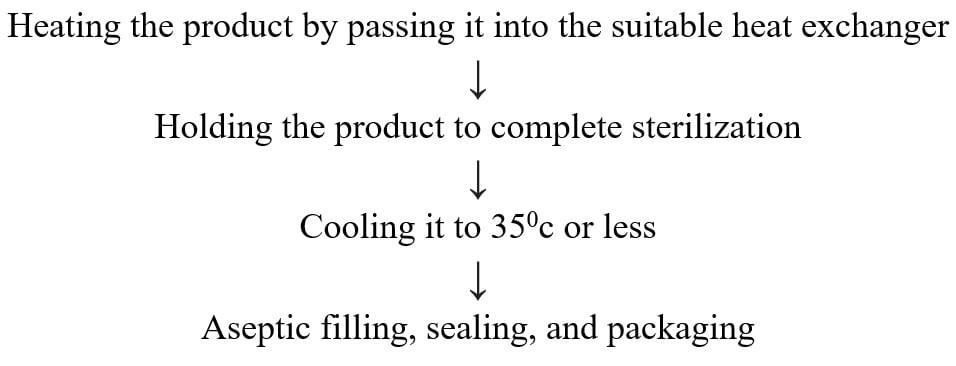

b. Aseptic sterilization (Processing)

- It is a type of heat sterilization that is conducted for a continuously flowing food supply chain.

- This technique is applied in the product before packaging so that there is no significant effect on the organoleptic and nutritional quality of the food product.

- This technique is applied for such products which are unsuitable for in-package sterilization.

- This technique can be applied for the sterilization of products, sterilization of packaging materials, maintenance of sterility during filling and sealing operations.

References

- Potter NP (1987), Food Science, CBS Pub, India

- Rahman MS (1999), Handbook of Food Preservation, Marcel Dekker, Inc, NY

- Desrosier EN (1963), The Technology of Food Preservation, AVI Publishing Company, New York