The shelf life of different perishable food products can be prolonged with the application of different gas treatments. In food preservation, the gas treatment uses gases like nitrogen, carbon dioxide, oxygen, or their mixture in different ratios to extend the food products’ shelf.

Gas treatment is an important tool in food preservation and packaging technology that ensure food quality and safety.

- Modifying or controlling the food products’ atmosphere can help extend food shelf-life or make food safe from degradative changes that lead to microbial spoilage or other deterioration.

- Especially fruits and vegetables are preserved by controlling or modifying the atmosphere or slowing the respiration rate.

- Also, other food products, including meat and cereal grains, are being preserved, controlling the atmosphere of storage.

- Respiration is the major concern during storage, where fruits and vegetables consume oxygen and release carbon dioxide.

- Based on respiration, fruits can be of two types:

- Climacteric fruits – (which can ripe after harvest due to the production of ethylene along with an increased rate of respiration)

- Non- climacteric fruits – (which cannot ripe after harvest, have no proper respiration, and have a low level of ethylene production)

Interesting Science Videos

Techniques to slow down respiration rate and physiological changes

- Reducing the temperature

- Reducing oxygen level

- Increasing carbon dioxide

- Maintain desirable humidity according to fruit types

Principle of gas treatment for food preservation

The main principle of gas treatment in food preservation is to create an atmosphere around the food that avoid the growth of spoilage microorganisms, maintaining safe, fresh, and quality food product.

- Use of proper concentrations of carbon dioxide gas or mixed with nitrogen gas can inhibit the growth of spoilage microorganisms reducing oxygen levels.

- Altered gas equilibria can change the rate of microbial and enzymatic spoilage.

- Evacuation of ethylene gas lowers fruits and vegetables’ ripening and aging process.

- Reducing oxygen concentration can inhibit aerobic meat spoilage microorganisms like Pseudomonas and Achromobacter.

- Anaerobic counts can be reduced using high CO2 concentration or a mixture of Nitrogen 70%, Carbon dioxide 25%, and 5% Oxygen.

Note: The use of different gases and their different concentrations varies per the food type.

Gases commonly used in food preservation

Carbon dioxide

- Important gas in modified atmospheric storage

- used to control the growth of microorganisms on the surface of foods; meat, dairy product, fruits, and vegetables

- It can be applied to the surface of food products in the form of dry ice as a surface cleaner.

Nitrogen

- An inert gas, which helps to create a protective atmosphere around food and also acts as a space filler gas

- Often used in modified atmospheric storage

- Nitrogen injection techniques can be used to prevent spoilage microorganisms in sealed-packed food products

- extend the shelf life of fresh products, meats, and dairy products

Oxygen

- Reducing the oxygen level in the food product’s atmosphere can help reduce aerobic microorganisms.

- It is monitored and mixed with other gases in MA and CA storage systems.

Argon, Helium

- These inert gases often combine with other gases N2, CO2, O2 MA storage and packaging.

The role of different gases in microorganisms will depend on the specific environment and type of microorganism.

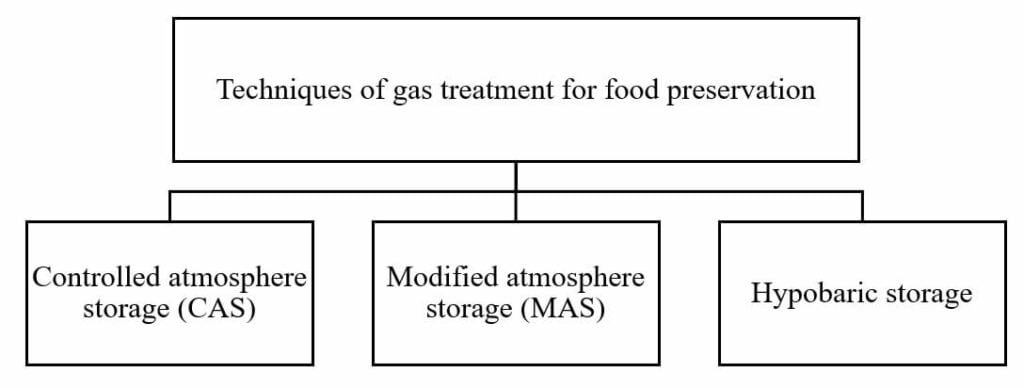

Different types of storage techniques for food preservation

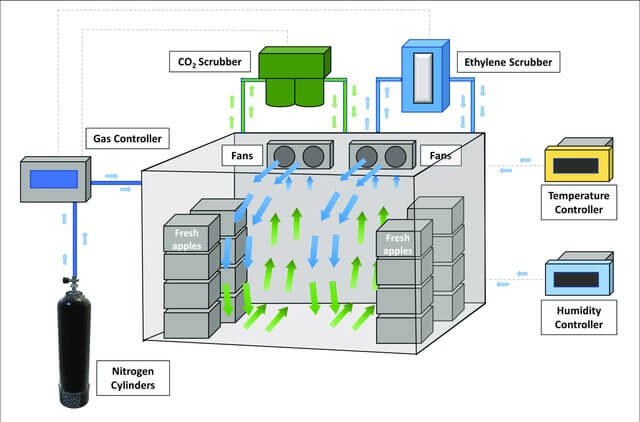

1. Controlled atmosphere storage (CAS)

- Controlled atmosphere storage is the storage technique in which the atmosphere’s composition is altered from that of air, and the proportion of gases like CO2, O2, and inert filler N2 is monitored and maintained in the control state.

- Low temperature is maintained while storing food products in CAS.

- The proportion of gases is controlled and monitored, usually oxygen is lowered and carbon dioxide is increased, nitrogen is used as an inert filler and other gases like ethylene, Carbon monoxide, fumigants, etc. may be added at low concentrations.

- Principle of CAS:

- Low temperature

- Increased carbon dioxide concentration

- Decreased oxygen concentration

2. Modified atmosphere storage (MAS)

- MAS is different from CAS in terms of the degree of control of gas concentrations, in MAS there is no active control of gas concentration.

- MAS deals with modifying the atmosphere either actively (addition or removal of gas) or passively (gases during respiration).

- This technique is cheaper as compared to CAS but results in shorter storage life.

Advantages of using CAS or MAS

- Increases shelf-life of the product

- Lowering rate of respiration

- Delay ripening of fruits

- Lowers the incidence of storage disorders like; oxidative damage and enzymatic browning

Disadvantages of the atmospheric storage system (CAS or MAS)

- Prevention of desirable ripening; irregular ripening of bananas and tomatoes

- Increases post-harvest disorders like sprouting in potatoes and brown heart in apples

- Development of off-flavor

- Physiological disorders like tissue injury, and internal browning may arise

- Accumulation of organic acids at a toxic level

3. Hypobaric storage

- Hypobaric storage is a form of the controlled atmosphere storage system in which product is refrigerated storage under-maintained reduced pressure (lower than atmospheric pressure) and high humidity.

- In this technique amount of oxygen is reduced with a decreased amount of air, but high humidity is maintained to prevent product dehydration.

- In this technique, products are placed in a flowing stream of air substantially saturated with water (RH= 80- 100%), at reduced pressure (4-400 mmHg absolute), and a controlled temperature ( -2 to 15°C).

- Reducing pressure in this system mainly aims to improve air through-put or facilitate the addition of different gas mixtures.

- Release and accumulation of vapors, accumulation of undesired gaseous by-products, and other noxious gases are flushed out during hypobaric storage.

References

- Potter NP (1987), Food Science, CBS Pub, India

- Rahman MS (1999), Handbook of Food Preservation, Marcel Dekker, Inc, NY

- Desrosier EN (1963), The Technology of Food Preservation, AVI Publishing Company, New York.