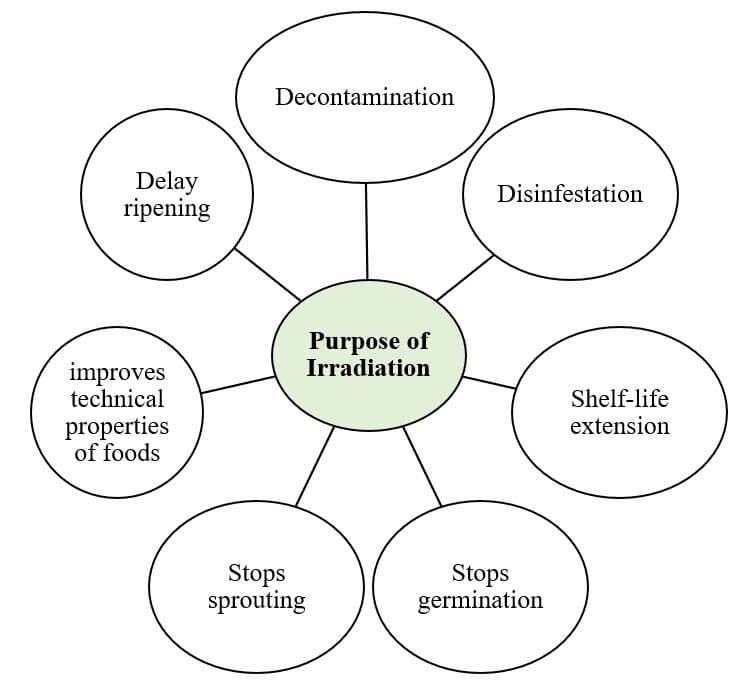

Food irradiation is the food preservation technique in which food is exposed to ionizing radiation beams (gamma rays, electron beams, and X-rays) to eliminate food spoilage and pathogenic microorganisms, pests, insects, etc.

Also, this technique extends the shelf-life of fresh fruits and vegetables by controlling normal processes like ripening, maturation, sprouting, and aging.

The food irradiation process is called cold sterilization (or pasteurization) because this process does not produce significant heat; therefore, nutritional and organoleptic properties are preserved compared to other thermal techniques.

The term radiation refers to the number of photons emitted from a single source, while irradiation refers to the process of exposing emitted photons or radiation to the surface.

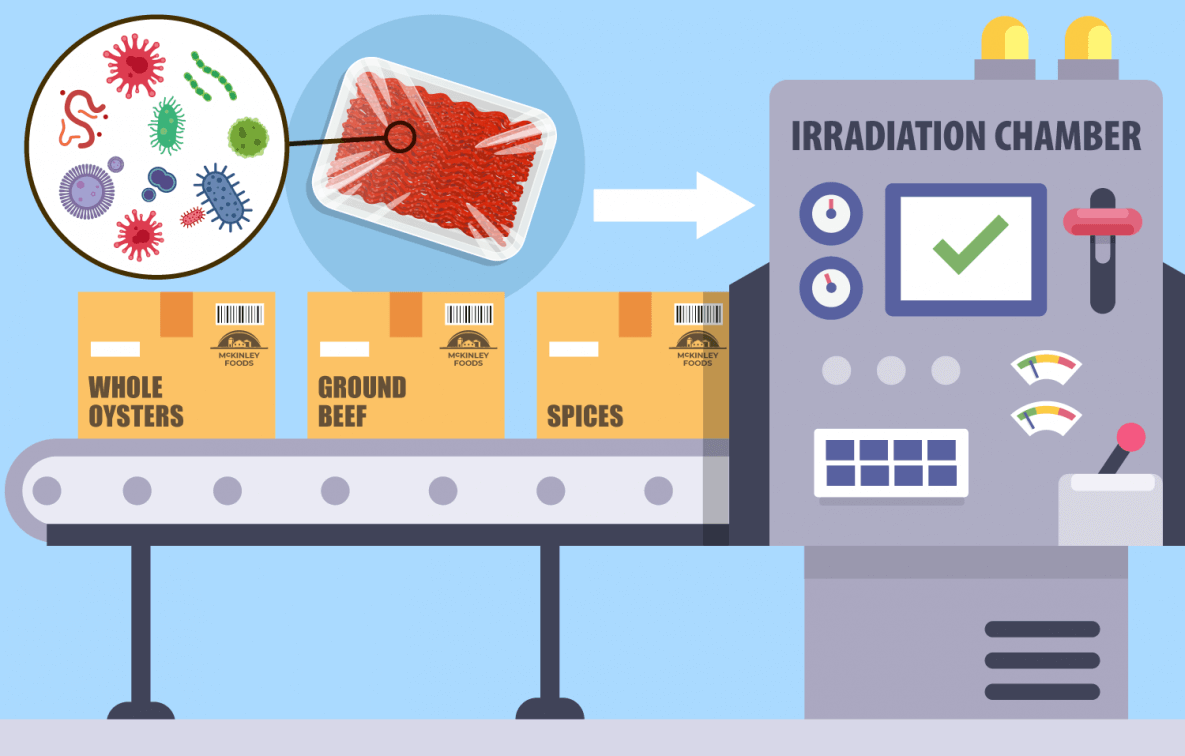

A predetermined irradiation dose can be applied to either prepackaged foods (intended for direct consumption) or food in bulk containers.

Irradiated food should be labeled with the international logo mentioning “irradiated food” or “treated with ionizing radiation.”

Interesting Science Videos

Significant events in the history of food preservation by Irradiation

1895 – Discovery of X-rays

1905 – First patent for using ionizing radiation to preserve food

1950 – Research on food irradiation begins

1953 – First commercial application of food irradiation

1958 – FDA approval for using irradiation to sterilize food products

1963 – FDA approved irradiation to control insects in wheat and wheat flour

1980 – CODEX Alimentarius adopts guidelines for the use of irradiation in food preservation

1986 – FDA approved irradiation to control Trichinella in pork products

1990s – EU approves use of irradiation for insect disinfestation and microbial decontamination of spices and herbs.

1990 – Irradiation is approved for pathogen control in Meat and poultry

2000 – approved for shell eggs

2003- WHO and IAEA issue joint statement endorsing safety and efficacy of food irradiation

Radiation dose

- The quantity of radiation energy absorbed by the food is called radiation dose.

- The unit of radiation dose is called gray (Gy).

- 1 Gy is equal to one joule per kilogram.

- According to CODEX (general standard for irradiated food), the maximum dose delivered to food should not exceed 10kGy.

- The food and Drug Administration (FDA) is responsible for regulating the source of radiation and dose of radiation that are used to irradiate food.

- The use of appropriate radiation doses is the most critical factor in food irradiation.

Different forms of irradiation treatment for sterilization

- Radurisation (radiate, prolong): It is a type of radiation treatment in which food products are treated in radiation to increase or prolong their shelf-life during storage maintaining its natural quality. This mode aims to inhibit germination, pest control, slow germination, destruction of pathogenic parasites and microorganisms. This mode applies low dose of radiation.

- Radicidation (radiate, kill): This radiation treatment involves use of higher dose of radiation to selectively kill microorganisms, such as Salmonella. This technique involves the treatment of food products with dose 2-10kGy, which is technically safe for human health.

- Radappertisation (radiate, canning food): It is a form of industrial sterilization that involves use of highest doses of radiation (10- 50 kGy) to destroy all microorganisms present in the food products. It is specially designed for canned food manufacturers. It is applicable to sterilization of spices, meat products, and dietetic food for sick people.

Three kinds of radiation are used in irradiators

- Gamma-rays from radionuclides 60Co or 137Cs

- Ionizing radiation emitted from radionuclides.

- High penetration capacity

- Good for industrial scale

- Electron beams from machine source

- Generated from electron accelerators.

- Low cost

- Have a maximum penetration depth of up to 8 cm only.

- Applied to the food surface spread in a thin layer.

- X-rays from the machine source

- Generated from an X-ray generator.

- Good penetration capacity as compared to electron beams.

Factor affecting food irradiation treatment.

- Type of food

- Radiation dose

- Treatment plant design

- Exposure time and temperature

Features of food Irradiation

- Cold sterilization

- Effective in lengthening the shelf-life of fresh fruits and vegetables.

- Green technology

- Nutritional stability of irradiated food

- Minimal loss in texture, flavor, aroma, and color of food

- It does not make food radioactive.

Principle of food irradiation

- Machines, principally electron accelerators, X-ray generators, or radionuclides, were designed to generate safe ionizing radiation.

- Accelerated electron beams can penetrate food (up to 8 cm)

- Direct effect: When electromagnetic radiation or particle beams directly strike a molecular complex in biological material, altering or destroying its biological function which can lead to chromosomal disorders or mutations. However, direct effect is considered less important in food preservation.

- Indirect effect: Ionizing radiation activates atoms in high moisture foods, producing free radicals through the radiolysis of water. Highly reactive hydrogen (H.) and hydroxyl (OH.) radicals are produced, which combine to form hydrogen, hydroxy, and hydroperoxyl radicals. Oxygen participates in the reaction to form hydroperoxyl radicals, which play a major role in microbial inhibition through their oxidative effect. These free radicals interfere with biochemical reactions and alter molecular structure, including breaking single and double-stranded DNA molecules by abstraction of hydrogen and elimination of phosphate, as well as hydroxylating purine and pyrimidine bases.

The reactions involved in the radiolysis of water include:

- Ionization of water:

H2O + energy → H2O+ + e–

- Formation of hydroxyl radical:

H2O+ + e– → H+ + OH

- Formation of hydrogen radical:

H2O + e– → H + OH–

- Recombination reactions:

H+ + H → H2

OH + OH → H2O2.

- Other reactions:

H + OH → H2O

H + H2O → H2 + OH

OH + H2O2 → H2O + HO2

H + O2 → HO2

HO2 + HO2 → H2O2 + O2

Application of Irradiation in Foods

- delays the ripening of green bananas.

- Inhibit sprouting of potatoes and onions.

- prevents greening of potatoes

- softens legumes and shortens their cooking time.

- increases yield of juices from grapes

- The speed drying rate of plums.

| Dose range (kGy) | Application on food products | Objective of irradiation |

| 0.05 – 0.15 | Potatoes, onions, garlic, yams | Inhibition of sprouting |

| 0.1 – 0.3 | Meat | Destruction of parasites |

| 0.1 – 0.5 | Grains, flour, coffee beans, dried fruits | Insect disinfestation |

| 1.0 – 5.0 | Fruits and vegetables | Reducing of microorganisms |

| 0.5 -1.5 | Mushroom, fruits | Delay maturation |

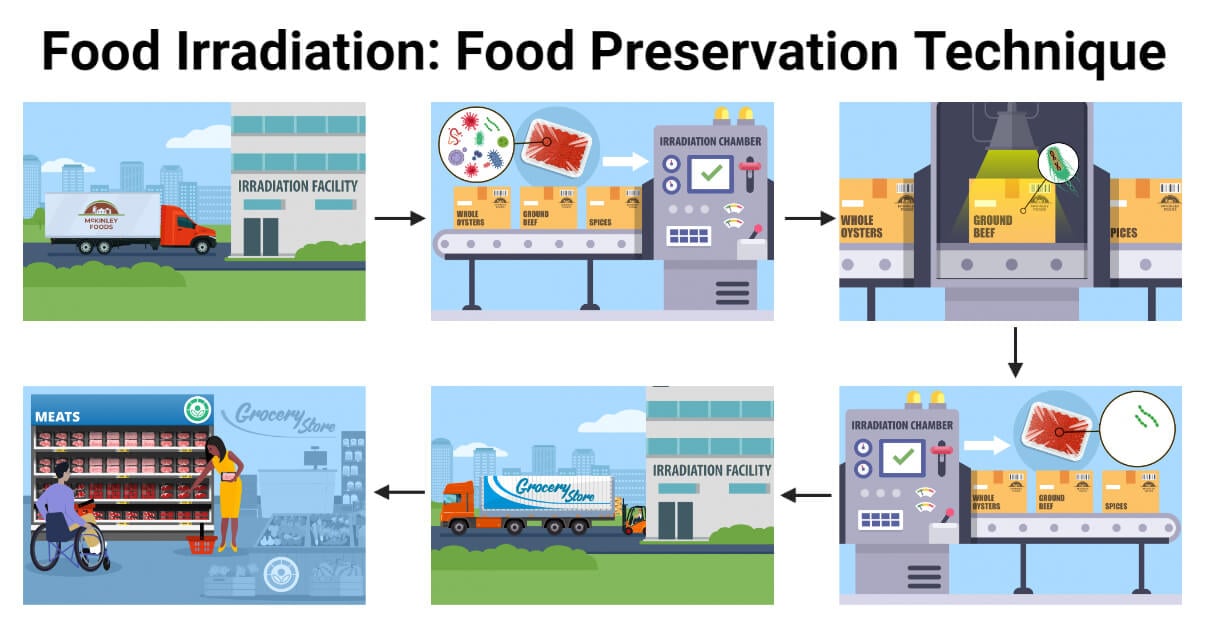

How is food irradiated?

Disadvantages of Food irradiation

- High initial cost

- Public perception

- Changes in sensory properties

- Regulatory issues

- Limited effectiveness against certain microorganisms

- Risk of unintentional over-irradiation

- Irradiation-resistant microorganisms can produce toxins.

- The potential for the formation of harmful by-products

Irradiated food must be labeled with the following symbol called Radura.

References

- Potter NP (1987), Food Science, CBS Pub, India

- Rahman MS (1999), Handbook of Food Preservation, Marcel Dekker, Inc, NY

- Desrosier EN (1963), The Technology of Food Preservation, AVI Publishing Company, New York

- https://www.cdc.gov/foodsafety/communication/food-irradiation.html