- Pasteurization is one of the most crucial phases in the preservation and a necessity for food safety.

- Food must be pasteurized to destroy disease-causing germs and significantly lower spoiling organisms.

- Pasteurization is utilized in various food and beverage industries, but dairy processing uses it the most.

- Pasteurization is commonly associated with milk, for which it is used worldwide.

- It is known as “moderate heat treatment” to prevent enzymatic and microbiological deterioration.

- By applying heat up to 100°C, heat-labile spoilage organisms such as non-spore-forming bacteria, yeast, and molds are eliminated.

- Due to the high heating and cooling demand levels, pasteurization is often an energy-intensive process.

- Pasteurization works best with other preservation techniques like concentration, acidity, and chemical inhibition.

- In pasteurizing, two processes can be used: slow and rapid.

- Slow pasteurization uses higher pasteurization temperatures longer; typical temperature-time combinations are 75°C for 8 to 10 minutes or 63 to 65°C for 30 minutes.

- Rapid, high, or flash pasteurization only requires a few seconds at pasteurization temperatures of at least 85 to 90°C. Combinations of temperature and duration that are common include 88°C (190°F) for one minute, 100°C for 12 seconds, and 121°C for two seconds.

Interesting Science Videos

Pasteurization History

- Louis Pasteur, a French scientist, developed pasteurization in the nineteenth century. He treated wine and beer with this method.

- In 1862, this procedure used a high-temperature, short-time (HTST) method for the first time.

- In the early 1900s, technology developed swiftly, inspiring the development of numerous pasteurization techniques.

- Chicago passed the first law requiring the pasteurization of milk in 1908.

- The holding method, known as vat pasteurization, dominated technology in the first half of the 20th century. This method is based on batch heating the milk for 30 minutes at roughly 63 °C.

- But by the early 1940s, high-temperature short-time (HTST) continuous methods had already gained widespread industrial acceptance.

- As the procedure’s technology advanced, several temperature-application times were put out.

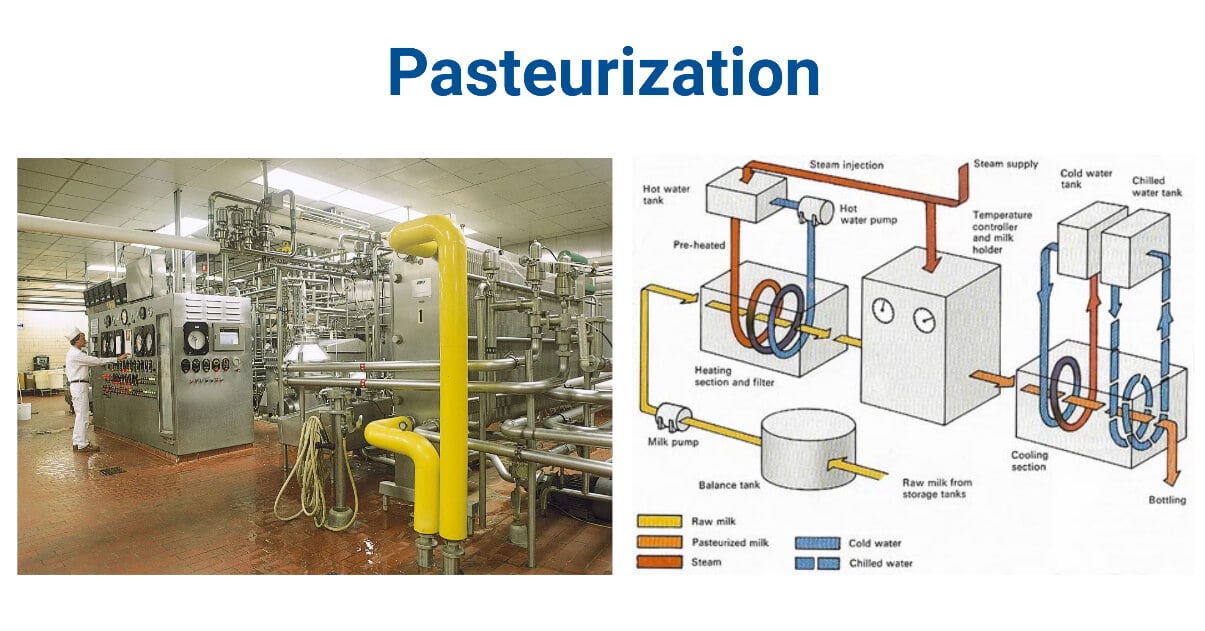

- Nowadays, plate heat exchangers are typically used to carry out HTST, a widely acknowledged technology for pasteurizing milk.

- A modern pasteurization facility’s various heating and cooling stages ensure the milk reaches the proper temperatures.

Purpose of Pasteurization

- It is not the goal of pasteurization to eradicate all microbes from food. Instead, it helps to lower the number of live germs, making them less likely to spread disease if proper conditions are applied to storage conditions.

- It is regularly utilized as a CCP in many HACCP plans and is widely used in the food sector.

- Pasteurization is typically employed to eliminate all disease-causing organisms (as in the case of pasteurizing milk) or to lessen the number of organisms that cause food to spoil, as in the case of vinegar.

- The pasteurization neutralizes all non-spore-forming pathogenic bacteria, most vegetative spoiling microorganisms, and slows or halts microbial and enzyme activity.

- It extends food’s shelf life at low temperatures, usually 4°C for a few days (for instance, milk) or months (e.g., bottled fruit).

Pasteurization of different foods and their purpose

| S.N. | Food | Main Purpose | Sub-purpose | Conditions of processing |

| 1 | Fruit juice (pH < 4.5) | Enzyme inactivation (pectinesterase, polygalacturonase) | Destruction of spoilage-causing microorganisms (Salmonella enterica, Cryptosporidium parvum) | 65°C for 30 min; 77°C for 1 min; 88°C for 15 s |

| 2. | Beer (pH < 4.5) | Destruction of spoilage-causing microorganisms (wild yeasts, Lactobacillus species) and (residual yeasts, Saccharomyces species) | Destruction of spoilage-causing microorganisms | 65°C–68°C for 20 min (in bottle); 72°C–75°Cfor 1–4 min at 900–1000 kPa |

| 3. | Milk (pH > 4.5) | Destruction of pathogens:Brucella abortus, Mycobacterium tuberculosis, Coxiella burnetti | Destruction of spoilage-causing microorganisms (Streptococcus laptis, Streptococcus cremoris) and enzymes | 63°C for 30 min; 71.5°C for 15 s64.4°C |

| 4. | Liquid egg | Destruction of pathogens (Salmonella seftenburg) | Destruction of spoilage microorganisms | 64.4°C for 2.5 min; 60°C for 3.5 min |

| 5. | Ice cream | Destruction of spoilage microorganisms. | Destruction of pathogens | 65°C for 30 min; 71°C for 10 min; 80°C for 25 s |

Types of Pasteurization

1. Vat Pasteurization or low temperature

- Vat pasteurizer consists of a temperature-controlled, closed vat.

- Additionally, it is called batch pasteurization or low-temperature, or prolonged pasteurization.

- The food product is brought to a temperature between 62 °C to 64 °C and maintained there for about 30 minutes, and then swiftly cooled.

- The shelf life of pasteurized food in a refrigerator is two to three weeks.

- The raw material is added into the pasteurization vat, heating it to the required temperature, maintained for the required period, utilizing cooling technology, and finally pumping the material out of the vat.

- In the dairy business, milk is thoroughly pasteurized in vats before making ice cream, cheese, yogurt, and other typical food items.

- Today, smaller businesses and items other than milk are the main uses for vat/batch pasteurization.

- However, significant corporations occasionally use it (e.g., fruit juices).

Advantages

- Vat pasteurization works effectively for low-volume items in bigger enterprises and small plants.

- They are particularly well suited to processing cultured products like buttermilk and sour cream, which require mixing for the incorporation of starter, several hours of quiescent holding for incubation, agitation for breaking the curd, and final cooling the tank in addition to being pasteurized and cooled.

Disadvantages

- Pasteurization in vats often occurs in batches and is, therefore, slow.

- Although manual controls are employed, the operator must always pay close attention to avoid overheating, over-holding, and burning.

- Since the vat cannot regenerate heat, heating, and cooling are relatively expensive.

| Product | Temperature | Time |

| Milk | 62 °C | 30 minutes |

| Cream, yogurt | 65 °C | 30 minutes |

| Eggnog, frozen dessert mixes | 69 °C | 30 minutes |

2. High Temperature/Short Time (HTST)

- HTST pasteurization is also referred to as flash pasteurization or the continuous method.

- HTST pasteurization stands for high-temperature, short-time processing.

- It is currently one of the most popular pasteurization techniques.

- The liquid is heated to temperatures between 71.5 °C to 74 °C for approximately 15 to 30 seconds or between 74°C to 76°C for 15 to 20 seconds, followed by rapidly cooling to between 4°C and 5.5 °C using a continuous heat exchanger.

- It targets harmful bacterial spores that are resistant (Clostridium botulinum spores).

- A typical refrigerated shelf-life for HTST pasteurized milk is two to three weeks.

- The HTST pasteurization should eliminate nearly all yeasts, mold, common spoilage, and harmful bacteria by achieving a 5-log reduction in the number of live microorganisms in milk.

Advantages

- The color and flavor are better preserved.

- Suitable for milk products, juice/puree-based goods, and legged beer products.

Disadvantages

- This approach can be used in fewer manufacturing facilities.

- It is pretty expensive.

3. Ultra pasteurization (UP)

- In the same way as the HTST process, ultra-pasteurization is also carried out at a higher temperature using slightly different tools.

- UP pasteurized products have a longer shelf life but still require refrigeration.

- Different dairy products require different pasteurization processes depending on the product’s fat level.

- Ice cream, dairy dessert mixes, cream, or processed cheese need stronger treatment, such as 70°C for 25–30 min. or 80°C for 25 s.

Advantages

- The shelf life of milk is greatly extended by ultrapasteurization.

Disadvantages

- The milk does not taste like conventional pasteurized milk and contains up to 20% fewer vitamins A, D, and E than conventional pasteurized milk.

- The shelf life of pasteurized milk is shorter once opened due to decreased levels of antimicrobials, helpful bacteria, and enzymes.

4. Ultra-High-temperature (UHT)

- Ultra-high temperature (UHT) is currently utilized to preserve milk.

- The milk is sterilized at 135°C for 2–5 seconds before packaging, then aseptically put into containers.

- Despite being left out of the refrigerator, UHT milk sometimes lasts six to nine months.

- UHT treatment is also anticipated to eliminate bacterial spores.

Advantages

- It has shorter processing times

- It exhibits longer shelf lives

Disadvantages

- Sterilization Reduces the Nutritional Value of Milk

- UHT Treatment uses a lot of energy

- The UHT Process changes the original flavor of milk.

- UHT milk packaging is not biodegradable.

Microorganisms killed by pasteurization

- Acid producers- Streptococci, Lactobacilli, Microbacteria, Coliforms, Micrococci

- Gas producers- Coliforms, Clostridium butyricum, Torula cremoris

- Ropy or stringy fermentation- Alcaligenes viscolactis, Enterobacter aerogenes

- Proteolytic organisms- Bacillus spp., Pseudomonas spp., Proteus spp., Streptococcus liquefaciens

- Lipolytic organisms- Pseudomonas fluorescens, Achromobactor lipolyticum, Candida lipolytica, Penicillium spp.

Comparison between different pasteurization techniques

| Criteria | VAT | HTST | UHT |

| Process type | Batch | Continuous | Continuous |

| temperature and time | 65 °C for 30 min | 72 °C for 15–30 s | 135–150 °C for a few seconds |

| Foods preserved | Buttermilk and sour cream | Milk, eggnog, frozen dessert mixes, fruit juices, etc. | Milk |

| Shelf life increase (milk) | Several days when refrigerated | 2–3 weeks when refrigerated | 6–9 months when aseptically packaged |

| Microbes killed | Vegetative pathogens | Vegetative pathogens | All bacteria and spores |

References

- Bousbia, A., Gueroui, Y., Boudalia, S., Benada, M., & Chemmam, M. (2021). Effect of High Temperature, Short Time (HTST) Pasteurization on Milk Quality Intended for Consumption. Asian Journal of Dairy and Food Research, 40(2), 147–151. https://doi.org/10.18805/ajdfr.DR-210

- Challis, C., Wilson, R. E., Kay, T., Tierney, M., & Todd, A. (2018). A review of pasteurisation process monitoring to support energy efficiency in the dairy industry. Eceee Industrial Summer Study Proceedings, 2018-June, 379–388.

- Chiozzi, V., Agriopoulou, S., & Varzakas, T. (2022). Advances, Applications, and Comparison of Thermal (Pasteurization, Sterilization, and Aseptic Packaging) against Non-Thermal (Ultrasounds, UV Radiation, Ozonation, High Hydrostatic Pressure) Technologies in Food Processing. Applied Sciences 2022, Vol. 12, Page 2202, 12(4), 2202. https://doi.org/10.3390/APP12042202

- Cifelli, C. J., Maples, I. S., & Miller, G. D. (2010). Pasteurization: Implications for food safety and nutrition. Nutrition Today, 45(5), 207–213. https://doi.org/10.1097/NT.0b013e3181f1d689

- Datta, N., Elliott, A. J., Perkins, M. L., & Deeth, H. C. (2002). Ultra-high-temperature (UHT) treatment of milk: Comparison of direct and indirect modes of heating. Australian Journal of Dairy Technology, 57(3), 211–227.

- Edition, T. (2008). Food microbilogy. In Food Microbiology. https://doi.org/10.1039/9781847557940-00182

- Fay, D. L. (1967). modern indutrial microbiology and botechnology. In Angewandte Chemie International Edition, 6(11), 951–952.

- Fernandes, R. (2009). MICROBIOLOGY HANDBOOK DAIRY PRODUCTS. http://www.leatherheadfood.com

- Motarjemi Y, Lelieveld H (2014). Food Safety Management : A practical guide for the food industry. Elsevier Inc.

- Húngaro, H. M., Peña, W. E. L., Silva, N. B. M., Carvalho, R. V., Alvarenga, V. O., & Sant’Ana, A. S. (2014). Food Microbiology. In Encyclopedia of Agriculture and Food Systems. https://doi.org/10.1016/B978-0-444-52512-3.00059-0

- Modi A, & Prajapat R. (2014). Pasteurization Process Energy Optimization For A Milk Dairy Plant By Energy Audit Approach. INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH, 3(6). www.ijstr.org

- Patel. (2013). Advances in Dairy Research. Adv Dairy Res, 9, 2021.

- Sarkar, S. (2015). Microbiological Considerations: Pasteurized Milk. International Journal of Dairy Science, 10(5), 206–218. https://doi.org/10.3923/ijds.2015.206.218

- Watts, S. (2016). A mini review on technique of milk pasteurization. ~ 99 ~ Journal of Pharmacognosy and Phytochemistry, 5(5). https://doi.org/10.1136/bmj.1.4286.261

- Zhao, J., Zhu, M., Wen, X., Jiang, Y., Kang, J., & Ni, Y. (2015). Glass transition and state diagram of mango. In Nongye Jixie Xuebao/Transactions of the Chinese Society for Agricultural Machinery (Vol. 46, Issue 4). https://doi.org/10.6041/j.issn.1000-1298.2015.04.033.