The preservation of foods with heating is one of the most important methods in food processing. Drying can be defined as the process of making a product dehydrated by evaporating free water with the application of heat. Drying is one of the oldest methods of food preservation.

Sun drying is a natural and widely used method for food preservation, but now novel drying techniques are evolved with sophisticated equipment. Drying in the sun is a natural process and dehydrating with heat from fire or other dryers is an artificial process.

Interesting Science Videos

Difference between sun drying and artificial dryer

| S.N. | Sun drying | Artificial Dryer |

| 1. | Use of heat from the sun | Use of heat from dehydrating unit |

| 2. | Low-quality product | Better quality of dried foods |

| 3. | Natural process, so no control to condition | Control over climatic conditions |

| 4. | Need more space to conduct drying | Less space is sufficient and is conducted within a chamber. |

| 5. | Risk of open field contamination from insects, birds, rodents, and dust | Proper sanitary condition is maintained |

| 6. | Less expensive | More expensive |

| 7. | Less value in a product | High-value product |

Purpose of drying

- The main purpose of drying is to extend the shelf-life of foods by lowering water activity.

- Lowering the water activity will inhibit microbial growth and enzyme activity.

- Drying helps reduce the weight and bulk of dried foods, reducing transportation and storage costs.

Principle of Drying

- State of water in food; Bound water and free water are the key concept of drying.

- Bound water refers to water that is unfreezeable, immobile, non-squeezable, and non-solvent water.

Bound water affects the drying process as more energy is required to remove bound water than free water.

- The main factor affecting the effectiveness of the drying process is the moisture and water activity (aw) of the food.

Moisture

It can be simply defined as the total water content in the food that might exist in the free or bound state.

Water activity

Water activity is the amount of free water present in a food product that is available for enzymatic activity or supports the growth of microorganisms, eventually leading to food spoilage.

| S.N. | Foods | Water activity (aw) | Shelf life | Food spoilage microbes |

| 1. | Fresh foods; meat, fish, fruits, vegetables, poultry | More than 0.98 | Days | Gram-negative bacteria like Pseudomonas, Members of Enterobacteriaceae; Escherichia coli, Proteus, and Shigella, and gram-positive bacteria like Bacillus cereus and Clostridium perfringens |

| 2. | Cured meat products, sausage, biscuits, cheese, bread, Margarine | 0.87-0.98 | Weeks | Yeast, molds, Salmonella, C. botulinum, Lactobacillus, Pediococcus, Gram-positive non-spore former |

| 3. | Salted food, syrups, flour, ham, fruit juice concentrated, Condensed milk | 0.80-0.87 | Month | Staphylococcus aureus, Most molds, Saccharomyces |

| 4. | Dried food; dried fruits, cereals, spices, nuts, dry milk | 0.60-0.80 | Years | Most of the fungi; Aspergillus, Eurotium, Penicillin |

| 5. | Rice, honey, jams | Below 0.60 | Years | microorganisms can remain viable but do not grow |

| S.N. | Foods | Moisture content (%) |

| 1. | Grains | 4-9 |

| 2. | Milk powder, coca powder | 7-10 |

| 3. | Whole egg powder, skim milk powder, dried fat-free meat, rice, legume seeds | 10-15 |

| 4. | Dehydrated vegetables, dried soups | 12-22 |

| 5. | Dried fruits | 18-25 |

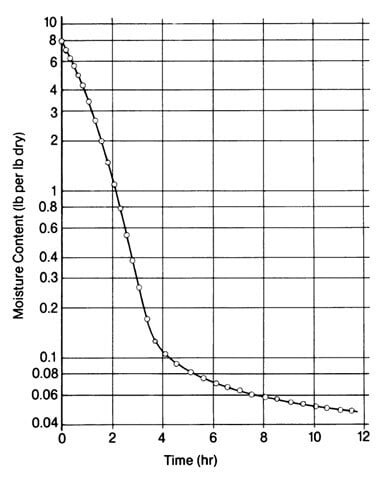

Stages of drying

The phenomenon of drying can be discussed under two periods:

- Constant rate period and

- Falling rate period

Constant rate period: When food in the dryer is applied with heat, water moves from the interior of the food at the same rate as it evaporates from the surface, and the surface remains wet until the certain critical moisture content is reached. This is known as the constant rate period. During this period, moisture is easy to remove.

Falling rate period: When the moisture content of food falls below the critical moisture content level, the drying rate slowly decreases, and the moisture of food enters equilibrium with the drying air. This is known as the falling rate period. During this period rate of water moment from the interior to the surface decreases compared to water evaporating from the surface. During this period, moisture is hard to remove, and the drying process is much slower.

During drying water moves from the interior of the food to the surface by

- Movement of liquid by capillary forces

- Diffusion of liquids

- Water vapor diffusion

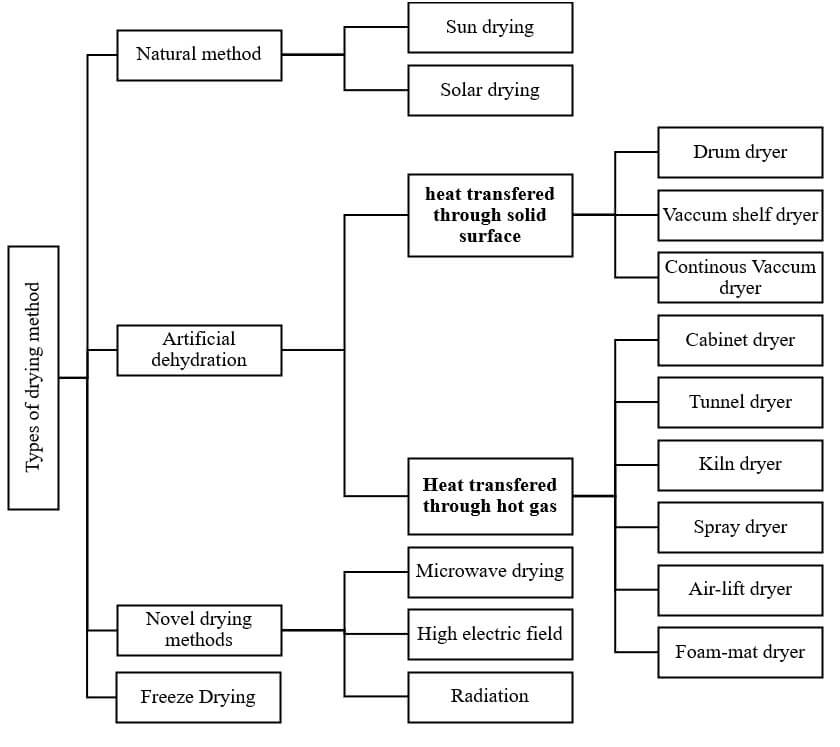

Types of dryer

Solid surface dryer

In this direr, heat is transferred to food through the solid surface, and water vapor is removed by a vacuum pump or, in some cases, by circulating the air.

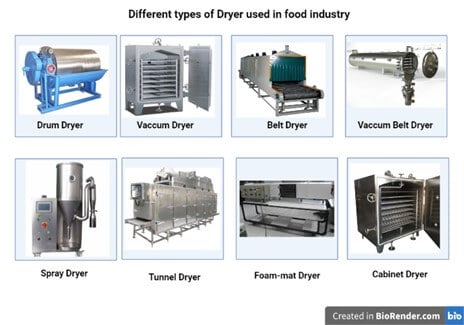

- Drum dryer: In this type of dryer slurry of product is deposited on the drum in the thin film, and heat is transferred through the drum wall. The rotating drum has 1 to 2 m in diameter and is heated with steam. The product will be recovered in the form of fine powder.

- Vacuum shelf dryer: It consists of a cabinet with hollow shelves where the heating medium is circulated, and the product is placed in pans on the shelves. During the treatment, the unit is closed and vacuumed. This setup is very expensive and used to prepare food products like citrus powder, tomato powder, etc.

- Continuous Vacuum dryer: In this dryer, the product is placed on the stainless steel belt, and heat is passed through the belt to the product film. It is also conducted in an enclosed setup under a vacuum.

Adiabatic dryers

In this type of dryer, heat is transferred into the dryer by hot gas. Hot gas transfers heat to the water in the food and carries out the water vapor thus produced.

- Cabinet dryer: Food product trays are placed in the chamber in which hot air generated from the heater is circulated by a fan, and the material is dried. It is less expensive with an easy setup and uses to dehydrate vegetables and fruits on a small scale.

- Tunnel dryer: The dryer is a 10-20m long tunnel-like structure in which trays of foods are placed, and hot air is blown across them. Trays are inserted from one end of the tunnel and taken out from another. It is also most common to dehydrate fruits and vegetables.

- Kiln dryer: This dryer has two storyed structure. An upper story has narrow slats in which pieces of food products are placed, and hot gas produced by the furnace in the lower story is passed through the product. Products like apple slices hop and potatoes are dried.

- Spray dryer: This dryer is used to dry solutions, pastes, or slurries. Products are dispersed as small droplets and dried with drying air. It can be conducted in the horizontal long chamber or conveyor carries out vertical long chamber in which settled dried products in powder form.

- Air-lift dryer: In this type of dryer, food products like potato granules are mixed with hot air and carried up a narrow column. When the product gets dried, it gets suspended in air due to air velocity incorporated. At the top of the drying column, air velocity is lowered, which helps to settle the product into a collector.

Foam-mat dryer

In this dryer, liquid foods are prefoamed using the edible foaming agent. Stable foam is then spread on the mat and dried using hot air. It is suitable for drying heat-sensitive, viscous, sticky, liquid food products. The foam layer of many liquids and semi-solid foods can be dried to about 2-3% moisture in about 12 minutes.

Freeze Drying

- Freeze drying (Lyophilisation) is the technique of food preservation in which water is frozen and then converted directly to vapor by sublimation.

- It combines two preservation methods; freezing and dehydration by sublimation.

- It is different from other techniques as frozen water moves from ice state to vapor without becoming liquid.

- Rehydration is very rapid and complete as compared to other drying processes.

- Freeze drying of foods helps to decrease water activity which inhibits microbial growth.

- It is used to preserve high-value foods with natural aromas or textures.

- Raw and cooked meats, Coffee, mushrooms, herbs, spices, strawberries, meats, seafood, cream, confectionery, enzymes, microbial cultures, etc., are preserved by freeze-drying.

Factors affecting the selection of dying methods

- State and composition of food product

- Porosity and hygroscopic nature of food product

- Properties of the desired finished product

- Heat susceptibility of the product

- Temperature tolerance and its effect on the quality of the product

- Capital and processing cost

- Environmental factors

Uses of the drying process for food preservation:-

Different dryer and food dried

| S.N. | Dryer | Food preserved |

| 1. | Drum dryer | Milk, vegetable juices, bananas |

| 2. | Vacuum shelf dryer | Citrus powder preparation |

| 3. | Continuous belt dryer | Vegetables |

| 4. | Foam-mat dryer | Juices |

| 5. | Spray dryer | Whole eggs, egg yolk, milk |

| 6. | Cabinet dryer | Apple, vegetables |

| 7. | Tunnel dryer | Fruits and vegetables |

| 8. | Conveyor dryer | Cereals, fruits, nuts, biscuits |

| 9. | Solar dryer | Fruits, vegetables |

Based on value addition to the product

| Low-value product | Cereals. Legumes, root crops |

| Intermediate value product | Vegetables, fruits, meat, fish |

| High-value product | Spices, herbs, medicinal plants, nuts, bioactive materials, enzyme |

Pretreatments before drying

- Blanching: proper blanching helps inactive naturally occurring enzymes in foods responsible for enzymatic browning and off-flavor development.

- Sulfur dioxide treatment: It helps to preserve texture, flavor, vitamin content(ascorbic and carotene), and the color of the food. Also, SO2 treatment helps to reduce enzymatic browning and acts as an antimicrobial agent.

- Salting or curing: This treatment is done before drying meat, fish, and cheese products. Sodium chloride and potassium nitrite act as osmotic dehydrator, reduce moisture and aids the drying process, and also acts as preservatives.

- Dipping in sulfite: Immersion of foods in solution with a concentration of less than 5% for less than 5 minutes helps to dehydrate the food and improve drying characteristics and quality.

- Cooking: Cooking products before drying helps to destroy microorganisms and decrease the water-holding capacity of products like meat.

Influence of drying on the nutritive value of food

There is no better quality of food than natural or original foodstuff. Drying also tends to cause loss of some vitamins and nutrients besides increasing the concentration of nutrients in the remaining mass. The dehydration method has far better quality and nutrient retention than sun drying.

| S.N | Influence on | Defects | Controls |

| 1. | Vitamin | Loss of water-soluble vitamins on pretreatment, oxidative damage of ascorbic acid and carotene, loss of heat-sensitive vitamin(thiamin), and Vitamin-D loss are great by drying. | Spray drying lowers carotene loss; freezing of fruits reduces vitamin-c loss in fruits; vitamin-a in milk can be retained by drum or spray drying, enriched milk with vitamin D before drying. |

| 2. | Proteins | High temperatures can decrease dietary value. | Low-temperature treatment to increase the digestibility of protein |

| 3. | Fats | Oxidation of fats is high in the higher temperature of dehydration | Low-temperature dehydration and use of antioxidants |

| 4. | Carbohydrates | Discoloration due to enzymatic or non-enzymatic browning in fruits | Use of sulfur dioxide |

References

- Potter NP (1987), Food Science, CBS Pub, India

- Rahman MS (1999), Handbook of Food Preservation, Marcel Dekker, Inc, NY

- Desrosier EN (1963), The Technology of Food Preservation, AVI Publishing Company, New York

Good article. Do you have information regarding infra red drying methods?

regards

Sanneliza