Temperature management is an important tool to control both physical and biological deteriorations in foods.

Low-temperature treatment applied during handling, transportation, and storage is the easiest and most effective method to extend the shelf life without losing quality.

Low-temperature treatment can be defined as removing heat energy from the foods, which consequently decreases the temperature or can change the state from water to ice. Low temperature (t) can be combined with other preservation techniques (hurdles) for effective preservation.

Refrigeration and Freezing are traditional low-temperature treatment methods of food preservation.

Interesting Science Videos

A. Refrigeration

- Refrigeration refers to storage at a temperature above the freezing point of food.

- The temperature of freezing refrigeration ranges from about 16°C down to -2°C.

- Commercial and household refrigerators are generally operated at 0 to 7.2°C as per the food type.

- Refrigeration is applicable to preserve perishable foods for days or weeks.

- This technique does not necessarily kill microorganisms but helps to inactivate the enzyme, which helps to protect food from rapid deterioration.

- This technique helps to maintain the organoleptic and quality attributes of many foods as natural.

Principle of refrigeration

Under low-temperature microbial growth is depressed, and enzymatic and chemical processes are slowed down.

Requirements for Refrigerated storage:

- Controlled low temperature

- Air circulation

- Humidity control

- Modification of gas atmosphere

Application of Refrigeration

It is applicable throughout the food supply chain; transportation, warehousing, retailing, storage, etc.

For the preservation of;

- Fresh foods (raw): Vegetables, fruits, Meat, Fish, egg

- Processed foods: Rice, Dal, Curry, and other cooked items

- Canned foods

- Drinks and beverages

Defects of Refrigerated storage:

- “Chill injury” to fruits and vegetables is refrigeration temperature is not maintained

- Storage of Banana and tomato under 13°C slow down the activity of natural ripening enzyme, which results in poor colors

- Also, refrigerated storage can bring the problem of flavor exchange between foods.

- Loss of vitamin C and other vitamins can be seen under refrigeration

- Some foods like bread are not refrigerated

B. Chilling

It is similar to refrigeration in which temperature ranges from 0°C to 8°C, above the freezing point of the food.

| S.N. | Temperature | Foods |

| 1. | ±1°C | Fresh fish, meat, sausage, smoked meat, breaded fish |

| 2. | 0°C to 5°C | Canned meat, milk, cream, yogurt, salads, pasta, soup, pizza, pastries, cakes, unbaked dough, etc. |

| 3. | 0°C to 8°C | Fully cooked meat, butter, cheese, fruit juices, vegetables, cooked rice, etc. |

C. Freezing

- Freezing refers to frozen storage in which temperature is maintained lower than the freezing point so that food is in frozen condition.

- Generally, good freezing requires a temperature of -18°C or below.

- Microbiologically, -18°C storage is not strictly required because most pathogens do not grow under 3.3°C, and food spoilage organisms do not grow under -9.5°C. But the application of -18°C is sufficient to retard enzymatic deterioration and to slow nonenzymatic reaction expect some cases.

- Freezing can preserve foods for months to years if a proper packaging method is adopted.

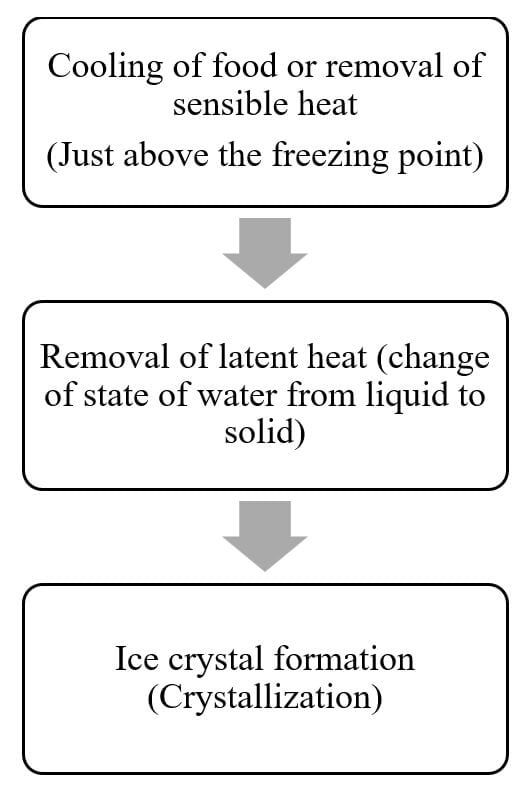

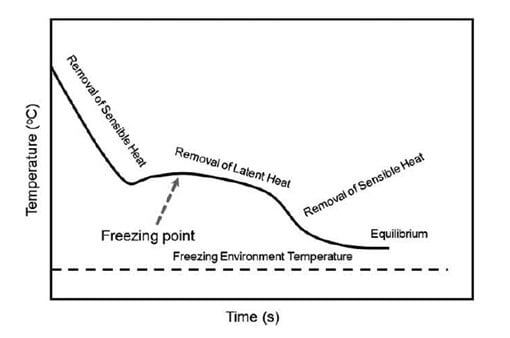

Principle of freezing

Food spoilage microorganisms grow rapidly at temperatures above 10°C, but psychrotrophs grow below 0°C as long as there is unfrozen water. So, making water unavailable by changing the state of water to crystal form can prevent microbial growth or destroy microbial cells to some extent.

Crystallization of water helps to increase the concentration of solutes which helps to increase osmotic pressure or reduce water activity. Low temperature lowers enzyme activity, and chemical reaction, as well as microbial growth, is minimized.

Stages of freezing

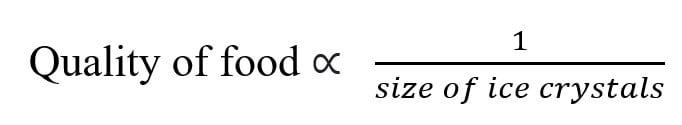

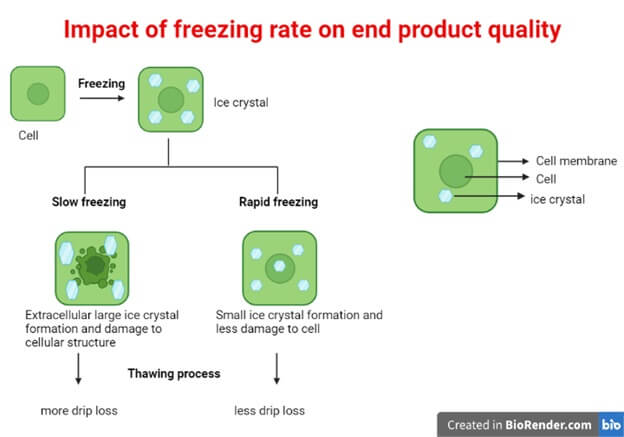

The quality of frozen food depends on the size of the ice crystals, and based on ice crystals formation, freezing can be categorized as follows;

Types of freezing

- Slow freezing

- Rapid freezing

| S.N. | Process characteristic | Slow freezing | Rapid freezing |

| 1. | Rate of decreasing temperature | ≤ 2°C / min. | ≥10°C / min. |

| 2. | Ice Crystal size | Large | Small |

| 3. | Location of ice crystals | Extracellular | Intracellular |

| 4. | Cell damage | Shrinkage of cell | Less damage |

| 5. | Drip loss on thawing | More drip loss | Less drip loss |

| 6. | Quality | Less food quality | Good food quality with better texture and flavor |

Effect of slow freezing

If the freezing rate is too slow, cells may rupture and release nutrients that drip during the thawing process and cause loss of organoleptic and nutritional value of food.

Application of freezing for food preservation

| Food | Water content (%) | Freezing point (°C) |

| Egg | 74 | -0.5 |

| Meat | 55-70 | -1.7 to -2.2 |

| Milk | 87 | -0.5 |

| Fruits | 87-95 | -0.9 to -2.7 |

| Vegetables | 78-92 | -0.8 to -2.8 |

Types of conventional freezing methods

- Plate freezing (contact with the cooled surface)

- Immersion freezing (contact with the cooled liquid)

- Cabinet freezing (contact with the cooled gas)

- Room or cabinet freezing

- Air-blast freezing

- Tunnel freezing

- Spiral freezing

- Fluidized Bed freezing

- Belt freezing

- Cryogenic freezing (use of cryogenic liquid)

| S.N. | Types of freezing methods | Food preserved |

| 1. | Plate freezing | Meat steaks, fish fillets, leafy vegetables |

| 2. | Immersion freezing | Canned foods, chicken, fruits, tomato slices, orange segments |

| 3. | Cold room | Beef carcass, chicken, fruits, vegetables |

| 4. | Air blast freezing | Fruits, vegetables, fish fillets |

| 5. | Tunnel freezing | Grains, soybean, fish fillets |

| 6. | Fluidized-bed | Carrot cubes, peas, shrimp, strawberries |

| 7. | Cryogenic | Ice cream, shrimp, berries |

The quality of frozen foods depends upon the following factors:

- Quality of fresh food

- Food composition

- Pretreatment methods

- Selection of freezing methods

- Freezing rate

- Good hygienic practices

- Packaging condition

- Thawing process

References

- Potter NP (1987), Food Science, CBS Pub, India

- Rahman MS (1999), Handbook of Food Preservation, Marcel Dekker, Inc, NY

- Desrosier EN (1963), The Technology of Food Preservation, AVI Publishing Company,New York