An autoclave is a machine that provides a physical method of sterilization by killing bacteria, viruses, and even spores present in the material put inside of the vessel using steam under pressure.

Autoclave sterilizes the materials by heating them up to a particular temperature for a specific period of time. The autoclave is also called a steam sterilizer that is commonly used in healthcare facilities and industries for various purposes. The autoclave is considered a more effective method of sterilization as it is based on moist heat sterilization.

Interesting Science Videos

Autoclave Parts/ Components

The simplest form of the autoclave is the pressure cooker type or laboratory bench autoclaves. The following is the detailed description of different components/ parts of an autoclave:

a. Pressure Chamber

- The pressure chamber is the main component of a steam autoclave consisting of an inner chamber and an outer jacket.

- The inner chamber is made up of stainless steel or gunmetal, which is present inside the out chamber made up of an iron case.

- The autoclaves used in healthcare laboratories have an outer jacket that is filled with steam to reduce the time taken to reach the sterilization temperature.

- The inner chamber is the case where the materials to be sterilized are put.

- The size of the pressure chamber ranges from 100 L to 3000 L.

b. Lid/ Door

- The next important component of an autoclave is the lid or door of the autoclave.

- The purpose of the lid is to seal off the outside atmosphere and create a sterilized condition on ht inside of the autoclave.

- The lid is made airtight via the screw clamps and asbestos washer.

- The lid consists of various other components like:

Pressure gauge

- A pressure gauge is present on the lid of the autoclave to indicate the pressure created in the autoclave during sterilization.

- The pressure gauge is essential as it assures the safety of the autoclave and the working condition of the operation.

Pressure releasing unit/ Whistle

- A whistle is present on the lid of the autoclave is the same as that of the pressure cooker.

- The whistle controls the pressure inside the chamber by releasing a certain amount of vapor by lifting itself.

Safety valve

- A safety valve is present on the lid of the autoclave, which is crucial in cases where the autoclave fails to perform its action or the pressure inside increases uncontrollably.

- The valve has a thin layer of rubber that bursts itself to release the pressure and to avoid the danger of explosion.

c. Steam generator/ Electrical heater

- An electrical steam generator or boiler is present underneath the chamber that uses an electric heating system to heat the water and generate steam in the inner and the outer chamber.

- The level of water present in the inner chamber is vital as if the water is not sufficient; there are chances of the burning of the heating system.

- Similarly, if the water is more than necessary, it might interfere with the trays and other components present inside the chamber.

d. Vacuum generator (if applicable)

- In some types of autoclaves, a separate vacuum generator is present which pulls out the air from the inside of the chamber to create a vacuum inside the chamber.

- The presence of some air pockets inside the chamber might support the growth of different microorganisms. This is why the vacuum chamber is an important component of an autoclave.

e. Wastewater cooler

- Many autoclaves are provided with a system to cool the effluent before it enters the draining pipes.

- This system prevents any damage to the drainage pipe due to the boiling water being sent out of the autoclave.

Autoclave Principle/ Working

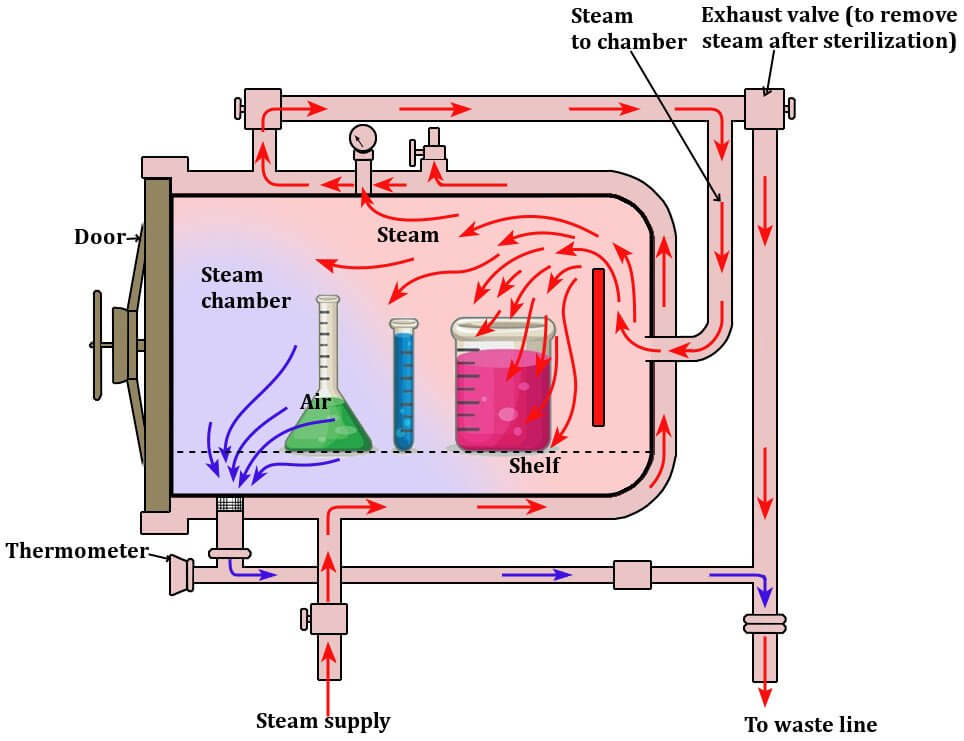

- The autoclave works on the principle of moist heat sterilization where steam under pressure is used to sterilize the material present inside the chamber.

- The high pressure increases the boiling point of water and thus helps achieve a higher temperature for sterilization.

- Water usually boils at 100°C under normal atmospheric pressure (760 mm of Hg); however, the boiling point of water increases if the pressure is to be increased.

- Similarly, the high pressure also facilitates the rapid penetration of heat into deeper parts of the material, and moisture present in the steam causes the coagulation of proteins causing an irreversible loss of function and activity of microbes.

- This principle is employed in an autoclave where the water boils at 121°C at the pressure of 15 psi or 775 mm of Hg.

- When this steam comes in contact with the surface, it kills the microbes by giving off latent heat.

- The condensed liquid ensures the moist killing of the microbes.

- Once the sterilization phase is completed (which depends on the level of contamination of material inside), the pressure is released from the inside of the chamber through the whistle.

- The pressure inside the chamber is then restored back to the ambient pressure while the components inside remain hot for some time.

Video: Principle and Working of Autoclave (Pharmaguideline)

Procedure for running an autoclave

In general, an autoclave is run at a temperature of 121° C for at least 30 minutes by using saturated steam under at least 15 psi of pressure. The following are the steps to be followed while running an autoclave:

- Before beginning to use the autoclave, it should be checked for any items left from the previous cycle.

- A sufficient amount of water is then put inside the chamber.

- Now, the materials to be sterilized are placed inside the chamber.

- The lid is then closed, and the screws are tightened to ensure an airtight condition, and the electric heater is switched on.

- The safety valves are adjusted to maintain the required pressure in the chamber.

- Once the water inside the chamber boils, the air-water mixture is allowed to escape through the discharge tube to let all the air inside to be displaced. The complete displacement can be ensured once the water bubbles cease to come out from the pipe.

- The drainage pipe is then closed, and the steam inside is allowed to reach the desired levels (15 lbs in most cases).

- Once the pressure is reached, the whistle blows to remove excess pressure from the chamber.

- After the whistle, the autoclave is run for a holding period, which is 15 minutes in most cases.

- Now, the electric heater is switched off, and the autoclave is allowed to cool until the pressure gauge indicates the pressure inside has lowered down to that of the atmospheric pressure.

- The discharge pipe is then opened to allow the entry of air from the outside into the autoclave.

- Finally, the lid is opened, and the sterilized materials are taken out of the chamber.

Video: How to use an autoclave (BioNetwork)

Types of Autoclave

There are different types of autoclaves present in the market, some of which are:

Pressure cooker type/ Laboratory bench autoclaves (N-type)

- These, as domestic pressure cookers, are still in use in many parts of the world.

- The more modern type has a metal chamber with a secure metal lid that can be fastened and sealed with a rubber gasket.

- It has an air and steam discharge tap, pressure gauge, and safety valve. There is an electric immersion heater at the bottom of the chamber.

Gravity displacement type autoclave

- This is the common type of autoclave used in laboratories.

- In this type of autoclave, the steam is created inside the chamber via the heating unit, which then moves around the chamber for sterilization.

- This type of autoclave is comparatively cheaper than other types.

Positive pressure displacement type (B-type)

- In this type of autoclave, the steam is generated in a separate steam generator which is then passed into the autoclave.

- This autoclave is faster as the steam can be generated within seconds.

- This type of autoclave is an improvement over the gravity displacement type.

Negative pressure displacement type (S-type)

- This is another type of autoclave that contains both the steam generator as well as a vacuum generator.

- Here, the vacuum generator pulls out all the air from inside the autoclave while the steam generator creates steam.

- The steam is then passed into the autoclave.

- This is the most recommended type of autoclave as it is very accurate and achieves a high sterility assurance level.

- This is also the most expensive type of autoclave.

Figure: Types of Autoclaves. Image Source: Microbe Online.

Uses of Autoclave

Autoclaves are important devices to ensure the sterilization of materials containing water as they cannot be sterilized by dry heat sterilization. Besides, autoclaves are used for various other purposes.

- They are used to decontaminate specific biological waste and sterilize media, instruments, and labware.

- Regulated medical waste that might contain bacteria, viruses, and other biological materials is recommended to be inactivated by autoclaving before disposal.

- In medical labs, autoclaves are used to sterilize medical equipment, glassware, surgical equipment, and medical wastes.

- Similarly, autoclaves are used for the sterilization of culture media, autoclavable containers, plastic tubes, and pipette tips.

Precautions

Although autoclaves are pretty simple to use, there are certain rules of precautions to be followed while operating an autoclave. Some of the important precautions to be followed while running an autoclave are:

- Autoclaves should not be used to sterilize water-proof or water-resistant substances like oil or powders.

- The autoclave should not be overcrowded, and the materials should be loaded in a way that ensures sufficient penetration of articles by the steam.

- TheThe items to be autoclaved should always be placed in a secondary container.

- Only autoclavable bags are to be used to autoclave packaged waste.

- To ensure sufficient penetration, articles should be wrapped in something that allows penetration by steam, and materials like aluminum foils should not be used.

- The items placed inside the chamber should not touch the sides or top of the chamber.

- The wastes and clean items should be autoclaved separately.

- Attempts to open the lid when the autoclave is working should never be made.

- Liquid components should never be autoclaved in sealed containers.

- The liquid inside the containers should only be filled 2/3rd of the total volume to prevent the spilling of the liquid.

- Plastic or polyethylene trays or containers should not be used as they might melt and damage the autoclave.

- Besides, never autoclave flammable, reactive, corrosive, toxic, or radioactive materials, household bleach, or paraffin-embedded tissue.

- The paper should not be placed directly inside an autoclave as it is a combustible substance. It should be autoclaved in a waste bag on a bio bag setting to prevent fire.

References

- Frazier WC and Westhoff DC. Food Microbiology. Tata McGraw Hill Publishing Company Limited. 1995.

- Banwart GJ (1989). Basic Food Microbiology. Chapman & Hall, New York, NY.

- Jay JM (2000). Modern Food Microbiology. CBS Publications and Distribution. Delhi.

- Collins CH, Patricia M, and Lyne JM (1995). Collins and Lynes Microbiological Methods 7th edition. Grange, Butter Worth, Oxford.

- Cappucino JG and Sherman N (1996). Microbiology, A Laboratory Manual 4th edition. Benjamin Cumings Inc. California

very detailed information

very useful informative about italmatic auto clave

The bestest website for study material thanks

This was really helpful but I request you to make notes on some most important topics like AIDS , HIV, Malaria , Polio virus and Tuberculosis etc..

Hello,

You have used an image from our blogger’s post. We would like to give you better images of autoclaves. Please let us know.

Yuvraj

iLabot Technologies

https://ilabot.com

For now, we are ok with the existing images. If we need the better one, we will contact you. Thank you.

This is really helpful to me especially for my preparation of examinations.

Thanks for the note easily to understand

Very clear and detailed explanation…… easy to understand.

question: what is the resistance of the heating elements if they have a specific resistance?

Thank you for information

Thank you for give good education

And simple language describe for understanding nursing students

Thanks for the notes

Looking for pics for Autoclave Accessories….. In pics including Door gaskets… Heating elements, Valves and Solenoids…. (Shivaki brand)

Yes

Nice work

It really help… Thank you

what is the heat dissipation of auto clave in the atmosphere

The description is amazingly and elaborate. I’m really informed by this article.

Wonderful, a must read for the scientific mind.

Wonderful explanation about autoclave. Keep it up

Nice lesson

Its a detailed article. Love it when someone genuinely focus on creating a truly relevant article for knowledge sharing.

Good Going. Keep it up.

– Krishan Kumar

Good notes

What a nice and detailed description of Autoclave is provided here, It is totally practical and close to reality in Pharmaceutical industry use of autoclave, I found only one complete article on autoclave which can satisfy my search. Thanks for the true fruitful information about autoclave.

Awesome description of autoclave, fully understood, as a biomedical Eng am able to identify faulty and repair easily, thanks