A water distiller is a special equipment designed to produce contaminant-free water by transforming water into vapor before condensing into a liquid state.

Water distillers replicate the Earth’s natural filtration process to produce water of unmatched purity. Impurities, including germs, heavy metals, and arsenic, are removed during evaporation because they cannot transform into steam. These impurities remain in the boiling chamber when the water changes from a liquid to a gaseous state. The distiller cools the evaporated water, transforming it into pure, mineral-free drinkable water. This distilled water is utilized in various settings, including fermentation, the medical industry, clinics, and organic chemistry labs. Autoclaves, batteries, and other various kinds of equipment also use it.

There are significant differences in the pollutants removed from deionized and distilled water, even though the terms are commonly used interchangeably. A water distiller system can filter away non-volatile organic molecules, most minerals, and a variety of chemicals in addition to charged ions. Over 95% of the minerals, including salt, sulfate, nitrate, and arsenic, will be eliminated by a clean, well-kept distiller. Biological pollutants like bacteria, viruses, and cysts are also eliminated.

Due to the high expense of operating and the gradual generation of treated water, distillers are often only used to produce smaller amounts of water for drinking and cooking. A reverse osmosis system (RO) is typically more appropriate when more treated water is needed.

Interesting Science Videos

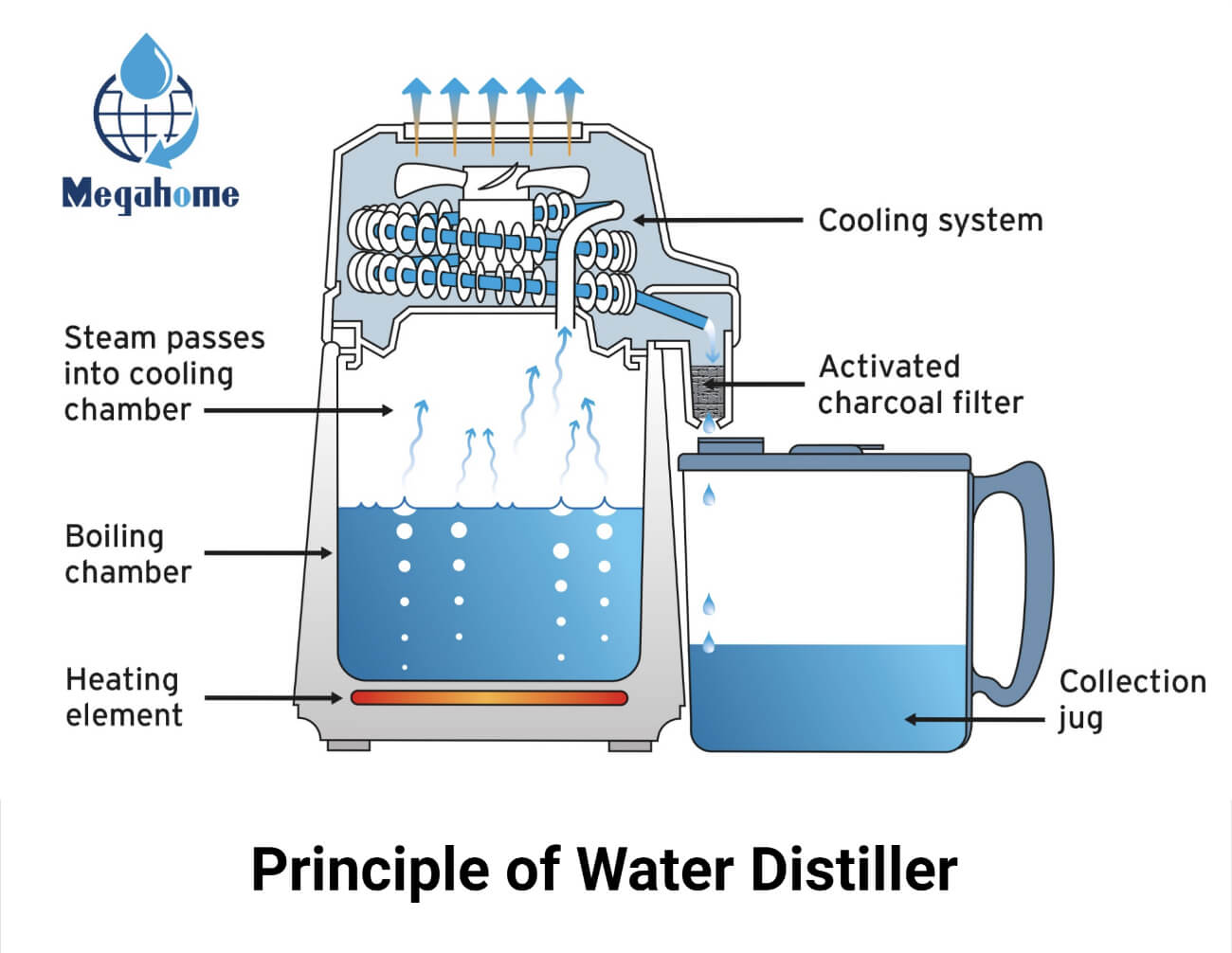

Principle of Water Distiller

Evaporation and condensation are the main mechanisms that drive distillers. Water is transformed into vapor by adding thermal energy while it is still in the liquid phase. This enables the molecules of water to dissociate from the molecules of other substances that have been diluted or combined with it. The collected water vapor is then sent via a condenser, which is cooled and transformed into liquid. The condensed water is then collected and placed in an additional storage tank. Compared to running water, distilled water exhibits pristine qualities and is essentially free of impurities.

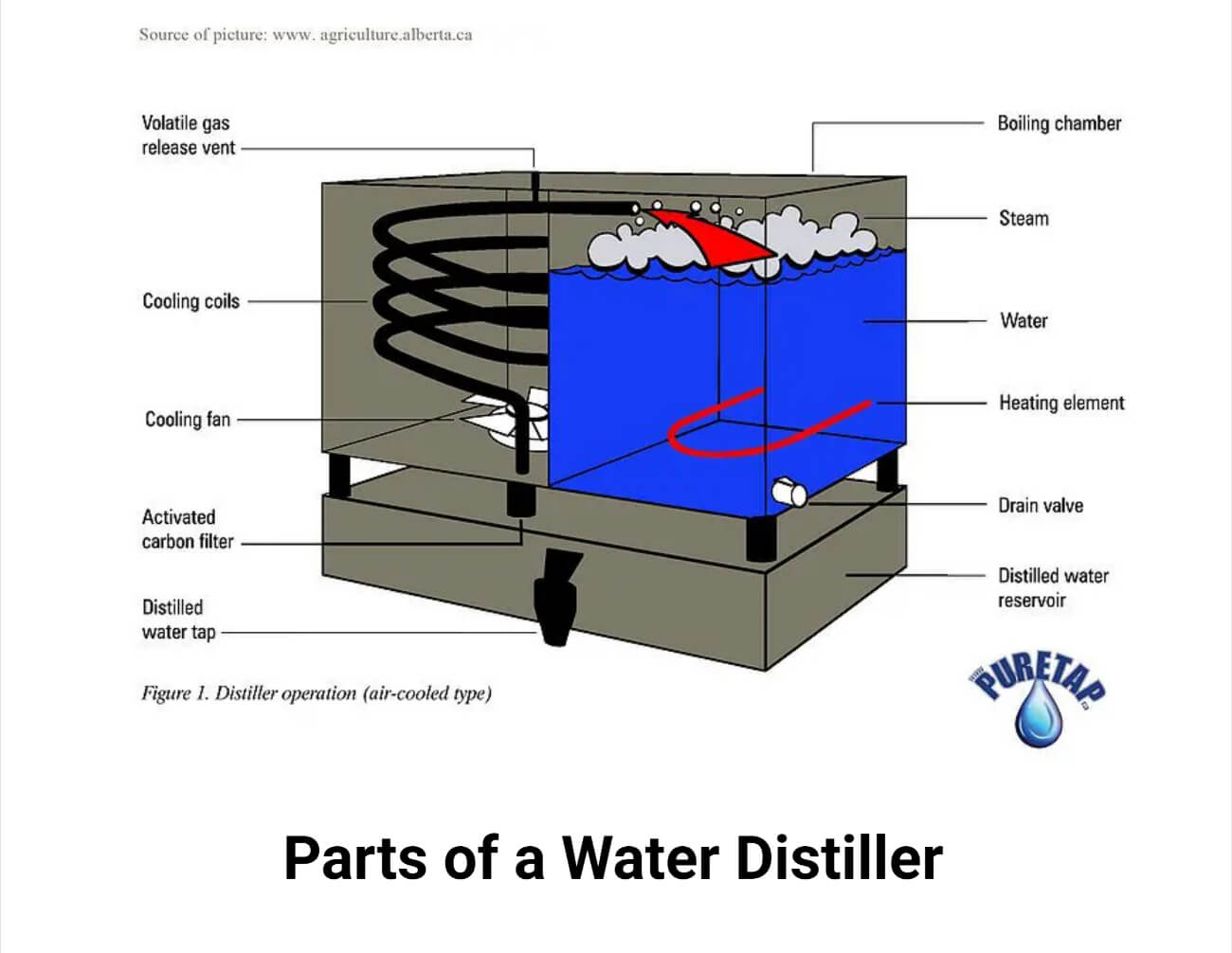

Parts of a Water Distiller

- Vapour generator/Boiling tank

Small-volume water distillers are made of glass, while larger-volume machines are made of stainless steel with copper, tin, or titanium coverings. It is designed to store the water to be distilled.

- Water Level Gauge

It facilitates the regulation of the quantity of water in the vapor generator. The device enables the amount of liquid that has evaporated to be recovered when the amount of water in the liquid phase in the boiling tank drops.

- Control valve

It is a device that allows water flow toward the vapor generator tank to be controlled mechanically or electromechanically.

- Immersion resistors

When an electrical current passes through them, it produces heat. These are sealed off by a ceramic cover and shielded from the external environment by a metal plate.

- Refrigerator water outlet

It is a line utilized for condensing the water vapor (cooling).

- Condenser

The device cools and returns the vapor to its liquid phase after losing thermal energy. The process is sped up by forced convection, which involves circulating low-temperature fluids (such as water or air) around the line where the vapor flows.

- Filter

Activated carbon filters are found in water distillers near the condenser or collector exit. As the vapor is being condensed, these remove any flavors or particles that could be there.

- Distilled water container

It is the container where the liquid that has undergone distillation is collected. Ionic contamination must be prevented by storing distilled water in designated plastic containers. Containers made of polytetrafluoroethylene, polyethylene, or polypropylene are typically used.

Types of Water Distillers

Distiller systems come in either manual or automatic configurations.

Manual distiller system

It can only produce 1 gallon of water at once. An individual should physically refill the system once the first gallon of water is created to produce the subsequent gallon of water. The amount of water a manual distiller can generate in an hour determines its capacity. Typically, 1-gallon-sized glass or plastic jars are used in manual distillation systems.

Automatic distiller system

A water pipe is connected to automatic water distillers, continuously creating pure water. When the holding tanks reach a specific level, systems are controlled by electronics or float valves to cease production. The daily output capacity determines an automatic system’s capacity. 3 to 25 liters of water can be stored by automatic distillation systems in a stainless-steel reservoir.

Based on their use at different places, they are categorized as follows:

Plumbing distillers

It can be included in your plumbing system. It might be an affordable option for water distillation. It requires some upkeep, such as emptying off sediments that collect on the bottom of the boiling chamber.

Household distillers

The single-effect distiller, which is simple to put in the workplace or kitchen counter, is one type of household distiller. The technology allows you to add the amount of water you need to distill, collect, and filter it.

Commercial distillers

With their multiple-effect distillers, these distillers have a daily output range of 75 gallons to millions of gallons. Different boiling chambers for more distilled water are included with commercial distillers.

Water Distiller Operating Procedure

The water distiller is operated in the following steps:

- The machine is plugged into a power source and turned on after adding water to the boiling chamber.

- When the water reaches the boiling point in the boiling chamber, it boils off. It turns into steam that rises into the cooling system leaving behind bacteria, fluorides, and other harmful substances.

- The vapor is condensed back into liquid form by the stainless-steel condenser.

- Through adsorption, the activated carbon filter eliminates the pollutants. The water droplets leave the distiller and are collected in the container.

Applications of Water Distiller

Some of the uses of distilled water are listed below:

- Distilled water promotes electrical flow in lead-acid batteries. It is also perfect for dilution of the coolant for the car’s radiator.

- A Continuous Positive Airway Pressure, common treatment therapy for people suffering from sleep apnea, utilizes distilled water in its humidification chamber, which prevents any mineral build-up or settling of bacterial growth.

- Neti pots are used for flushing a clogged nasal passage. Distilled water used with Neti pots ensures a sterile interior environment and relieves sinus congestion.

- Distilled water is used in various household appliances and cleaning tasks, such as ironing, preventing a scale build-up from minerals, aquariums, car washing, etc.

- Distilled water is also employed in the medical and scientific industries for experiments and cleanliness purposes. They are also used in hydroponic systems.

Advantages of Water Distiller

- Water distillers eliminate 99% of harmful contaminants from impure water, such as fluoride, lead, bacteria, etc.

- It provides health benefits by enhancing the skin’s appearance, sharpening mental performance, relieving headaches, etc.

- Unlike other water filtration systems like deionization and reverse process, water distillers are easy to install quickly.

Limitations of Water Distiller

- Electricity is needed for it to function. With the flow of electric current, heat energy is produced.

- The removal of all contaminants and minerals destroys the flavor of the water. A bland flavor may result from this.

- Purification of water through distillation is a time-consuming purification process.

- Since it raises the price of energy usage, it is not energy-efficient.

Precautions

- A reliable electricity supply should be established.

- Continuous supervision is required to ensure an adequate supply of cooling water, that the boiling flask doesn’t run dry (sometimes automatic protection is offered), and that the receiver isn’t overfilled.

- Checking for inorganic deposits and descaling the boiling chamber as necessary. In places with hard water, this needs to be done frequently.

- Make sure to look for cracks in every glassware.

- To make sure the system is leak-proof, regular inspections are required.

- To prevent the boiler from draining, make sure that a small amount of additional water is spilling out throughout both the boiling phase and the distillation-collection phase.

- When the overheating signal sounds, always try to identify the actual cause(s) of the boiler overheating before restarting the distiller.

- By carrying out regular cleaning processes, you can keep the distiller operating efficiently.

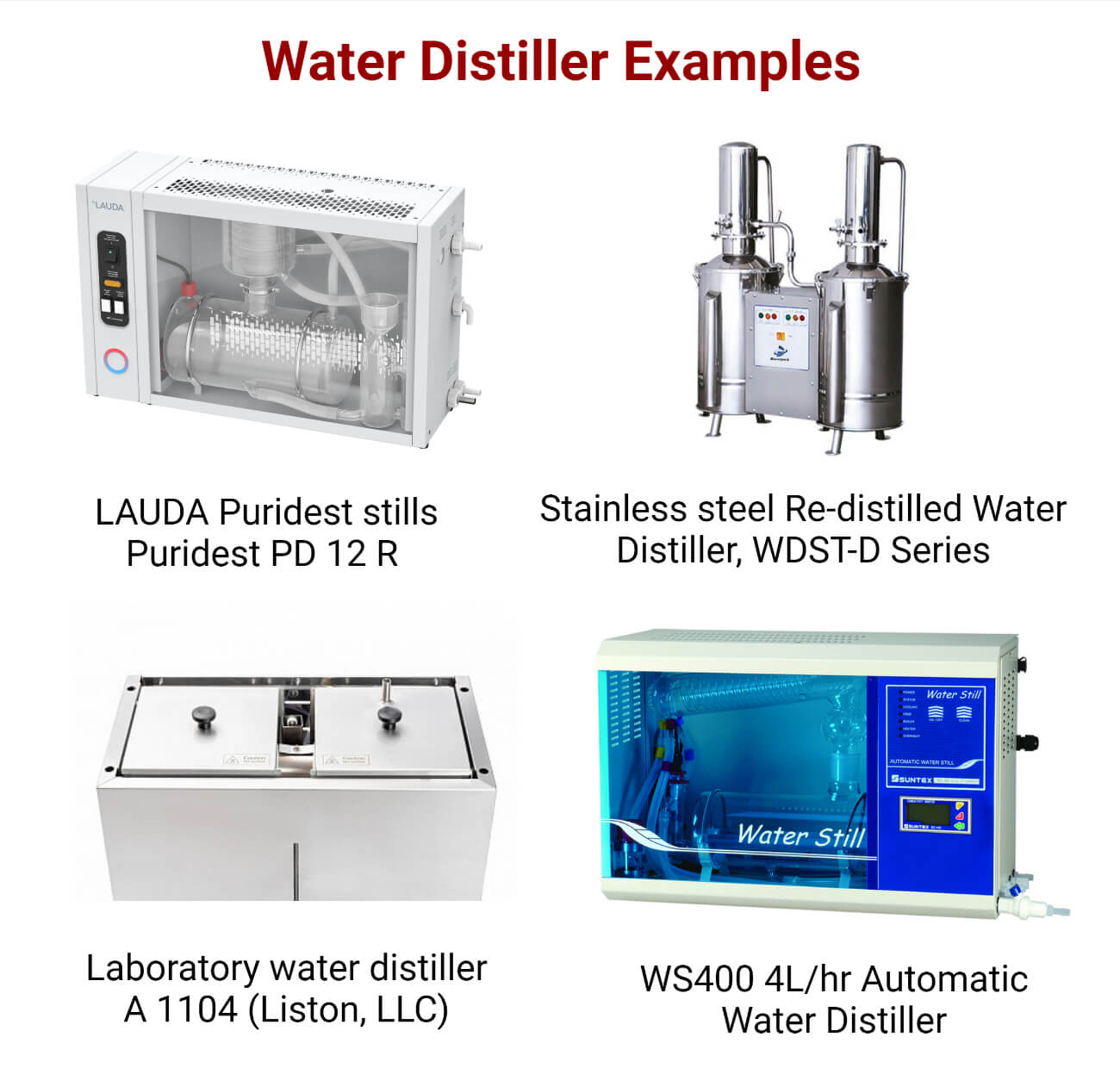

Water Distiller Examples

Laboratory water still Puridest PD series (LAUDA DR. R. WOBSER GMBH & CO. KG)

- They extract impurities from raw water of lesser quality, distill it, and destroy bacteria and other microorganisms.

- Puridest stills don’t need any expertise, and they don’t put a lot of strain on the linked raw water. By merely pressing a button, ultra-pure water can be extracted.

Laboratory water distiller WDST series (Bioevopeak)

- The entire machine is constructed of premium stainless steel.

- Large water flow, good cooling effect, and coil-type condensing structure.

- To conserve water, the cooling water is recycled into the evaporation barrel.

- The drain valve can drain the concentrated water in the barrel to improve the fouling conditions.

- The immersion heating tube made of copper has high thermal efficiency and a long lifespan.

Laboratory water distiller A 1104 (Liston, LLC)

- Presence of a solenoid valve-equipped electronic leak detection system

- Evaporator and condenser tank with easy access for quick maintenance (cleaning, etc.)

- Simple to replace condenser

- Evaporator level control that is automatic

- Monitoring the level of the distillate in the tank visually (through the glass level tube on the front panel)

Laboratory water distiller WS400 (Suntex Instrument)

- The SUNTEX Microprocessor automatic water still can be bench- or wall-mounted and has outputs of 4 or 8 liters per hour.

- The water continues to generate pyrogen-free water of the greatest quality.

- Additionally, purity is guaranteed by using robust, silica-sheathed heating components and borosilicate glass construction in the construction of the boilers and condensers.

References

- https://www.freshwatersystems.com/blogs/blog/what-is-a-water-distiller-and-how-does-it-work

- https://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/agdex715/$file/716d62.pdf

- https://slidetodoc.com/maintaining-a-water-distiller-o-principles-of-operation/

- https://www.pharmaceuticalsky.com/2021/08/sop-for-distilled-water-still.html

- https://www.wqpmag.com/softening-conditioning/distiller-equipment-components/article/10956704/what-are-water-distillers-how-do-they-work

- https://dashappliances.com/what-is-a-water-distiller/

- https://www.medicalexpo.com/prod/lauda-dr-r-wobser-gmbh-co-kg/product-105180-957916.html

- https://www.medicalexpo.com/prod/bioevopeak/product-301335-1049866.html

- https://www.medicalexpo.com/prod/liston-llc/product-110994-733320.html

- https://www.medicalexpo.com/prod/suntex-instruments/product-100041-980336.html

This article has help me and like it because it explains in details

Very much informational content, thankyou for sharing