Interesting Science Videos

Classification of the food based on pH

The microbial spoilage of food depends upon the pH of food therefore based on pH canned food can be divided as

- Low-acid canned food (pH > 5.2) includes meat products, milk, dairy products, and seafood.

- Acid canned food (pH 4.5-3.7) includes tomatoes, pears, figs, oranges, apricots, pineapples, etc.

- High acid canned food (pH < 3.7) includes pickled products, fermented products, ketchup, jams, jellies, etc.

Spoilage of Canned food and its causes

1. Physical damage leading to spoilage

The physical damages are caused by the following reasons which lead to microbial or chemical spoilages.

- The scheduled process was not delivered because of mechanical or personnel failure.

- Improperly or inadequately formed seals/seams

- Defective containers or defective lids of the containers

- Overfilling of the food

2. Chemical spoilages

The chemical spoilage is caused by the following reasons:

- Storage temperature

- Acidity of food

- The reaction between food and metal cans

- Insufficient exhausting during canning

- Presence of soluble Sulphur and Phosphorus in food

- The enzymatic action of food

This cause the defects such as:

- Swelling of can

- Discoloration of food

- Produces off-flavors in food

- Corrosion of the metals can leads to loss of nutritive quality of food.

- Cloudiness can be observed on syrups or brine or gravy.

3. Microbial spoilages

The microbial spoilage of canned food is caused by three reasons:

- Survival of spores of thermophilic bacteria

- Growth of survived thermophilic bacteria due to inadequate cooling, inadequate heat treatment, and improper storage temperature.

- Recontamination of microorganisms due to can leakage.

The canned food spoilage causing microorganisms are

A. Spoilage by spore-forming thermophilic bacteria

1. Flat sour spoilage

- In flat-sour spoilage, the products become sour due to the production of acid from carbohydrates with no can swelling.

- It only occurs in low acids foods and acid foods

- It is caused due to germination and growth of facultative anaerobic Geobacillus stearothermophilus, Bacillus coagulans, Bacillus thermoacidurans, and Bacillus stearothermophilus.

- The source of the organisms is usually plant equipment, sugar, starch, and soil.

2. Thermophilic anaerobic spoilage

- It is caused by anaerobic Thermoanaerobacter and Thermoanaerobacterium (eg Clostridium thermosaccharolyticum).

- There is a production of H2 and CO2 gases.

- The sour fermentation occurs at high temperatures in medium-acid canned foods.

- The gases swell the can resulting in the bursting of a can.

- They often produce a butyric or “cheesy” odor on food.

- This canned food spoilage occurs due to slow cooling, or hot storage

3. Thermophilic Anaerobic Sulfide Spoilage

- This spoilage is caused by Gram-negative obligate anaerobic spore formers Disulfotomacillum nigrificans, Clostridium bifermentans, and Clostridium sporogenes in low-acid canned food.

- There is an H2S production, and “rotten egg” odor in canned food with no swelling.

- The H2S thus produced are absorbed by food to produce iron sulfide resulting in black coloration of food and inside of cans.

- This canned food spoilage occurs due to under-processing, slow cooling, or hot storage

B. Spoilage by mesophilic spore-forming bacteria

1. Spoilage by Mesophilic Clostridium Species

- Several Clostridium spp., such as C. butyricum and C. pasteurianum in low acid canned food can survive and causes spoilage.

- These organisms ferment carbohydrates to produce volatile acids such as butyric acid and produce H2 and CO2 gases leading to swelling of the can.

- Proteolytic C. sporogenes, C. putrefaciens, and C. botulinum also cause the canned food spoilage.

- These organisms metabolize proteins and produce foul-smelling compounds, such as H2S, mercaptans, indoles, and ammonia.

- The insufficient heat treatment leads to the survival of mesophilic Clostridium spp.

2. Spoilage by Mesophilic Bacillus Species

- Mesophilic B. subtilis and B. mesentericus cause spoilage in low-acid canned food.

- These organisms cause spoilage in a poorly evacuated can.

- The insufficient heat treatment leads to the survival of mesophilic Bacillus spp.

- B. polymyxa and B. macerans also cause the canned food spoilage due to can leakage.

C. Spoilage by non-spore-forming bacteria

- These non-spore-forming bacteria survive in cans because of mild heat treatment (such as pasteurization) or due to leakage of a can.

- Thermoduric non-spore-forming bacteria include Enterococcus (E. faecalis and E. faecium), Microbacterium, Streptococcus thermophilus, Micrococcus, and Lactobacillus.

- Acid-forming Lactobacillus can survive in an under-processed canned food product.

- These bacteria produce CO2 leading to swelling of a can.

- Pseudomonas, Alcaligenes, Micrococcus, Flavobacterium, Proteus, and others can also cause spoilage in leaked canned foods.

D. Spoilage by yeast and mold

- The presence of yeast and mold in canned foods indicates under processing, leakage, recontamination, and poor evacuation.

- Fermentative yeast produces CO2 leading to swelling of a can.

- Commonly yeasts are found to grow on the surface of high acid foods such as pickled products.

- Torulopsis lactis and T. globosa cause blowing or gaseous spoilage on sweetened condensed milk, which is not heat processed.

- T. stellata causes spoilage in canned lemon and grows at a pH of 2.5.

- Molds species such as Aspergillus, Byssochlamys, Penicillium, and Citromyces are commonly found in canned food having high sugar content of up to 70-72%.

- The mold spoilage of canned food is characterized by moldy taste, odor, color fading, and presence of mold mycelia, and sometimes by slight swelling of the container.

Types of spoilage of canned food based on acidity and the defects caused by them in a can and their food product

| Canned food based on pH | Examples of food | Cause of microbial spoilage | Defects |

| Low-acid canned food (pH > 5.2) | Meat and meat products, milk, dairy products, and seafood. | Thermophilic flat-sour spoilage bacteria (Geobacillus stearothermophilus and Bacillus coagulans) | Can: flat, no gas, change in a vacuum

Product: reducing pH, souring, off-odor, and flavor, sometimes cloudy juice. |

| Corn and peas | Sulfide-producing anaerobic bacteria (Clostridium nigrificans, Clostridium bifermentans, and Desulfotomaculum nigrificans) | Can: flat, H2S produced are absorbed by food.

Product: blackening,” rotten egg” odor, iron sulfide precipitate |

|

| Corn and spinach | Mesophilic putrefactive anaerobic bacteria (Clostridium botulinum) | Can: swells, may burst by gas production

Product: partially digesting, increased pH, putrid odor, production of NH3, indoles, CO2, H2, and H2S |

|

| Acid canned food (pH 4.5-3.7) | tomatoes, pears, figs, oranges, apricots, pineapples | Mesophilic spore-forming bacteria (Bacillus polymyxa, Bacillus macerans, and Clostridium pasteurianum), | Can: Flat or swelling,

Product: coagulation, gas, and acid formation |

| Butyric anaerobic bacteria(Clostridium butyricum and Clostridium tertium) | Can: Swells, may burst

Product: Fermentation, gas production (CO2, H2), butyric odor |

||

| Aciduric bacteria (G. stearothermophilus and B. coagulans). | Can: flat, no gas, change in a vacuum

Product: reducing pH, souring, off-odor, and flavor, sometimes cloudy juice. |

||

| High acid canned food (pH < 3.7) | pickled product, fermented product, ketchup, jams, jellies, marmalades, fruits, and butter | Yeasts (Saccharomyces, Zygosaccharomyces) | Can: Swells, may burst, and leakage by gas formation.

Product: Fermentation, CO2 production, and yeasty odor. |

| Molds (B. fulva, Aspergillus, Penicillium, Citromyces) | Can: Swells, may burst, and leakage by gas formation.

Product: Fermentation, CO2 production, and yeasty odor. |

||

| lactic acid bacteria (L. brevis, L. mesentericus, L. dextranicum, L. mobilis) | Can: swells, may burst by gas, or swelling may be arrested

Product: Acid odor, Ropiness, and formation of acid and CO2 |

Preservation of canned food from microbial spoilage

- Canned food is thermally processed to ensure the “commercial sterility” of the food product for long-term storage.

- Canning itself is one of the heat-treated methods of food preservation however it doesn’t comply that it is free from microbial spoilage.

- The recontamination of canned food is more likely to occur due to various factors.

- To prevent microbial spoilage of canned food several others food preservation methods can be applied in combination with canning to extend its shelf life without deteriorating the nutritive quality of food.

1. Radiation

- Radiation sterilization of food (radappertization) requires exposing food in sealed containers to ionizing radiation to kill all spoilage-causing organisms.

- It is used to eliminate microorganisms on the surfaces of canned jars and their lids.

2. Preservatives agents

- Preservatives are substances that are capable of inhibiting or retarding the growth of microorganisms and are categorized as “Generally Regarded As Safe (GRAS)”.

- They include simple organic acids, sulfite, ethylene oxide, sodium nitrite, ethyl formate, LAB and bacteriocin,

3. Chilling storage

- The canned foods are stored at temperatures 0–5 °C.

- The main objective of chilling is to reduce the rate of microbial growth and its enzymatic activities which extends the shelf life of canned food.

What is Canning?

Canning is a food preservation method in which food contents are processed and sealed in a hermetically sealed container (such as metal, glass jars, plastic cans, thermostable plastic, or a multilayered flexible pouch).

- Canning is also known as Appertization from the name of its first inventor, Nicolas Appert.

- It is a great method for food preservation to extend its shelf life for a longer period.

- The main objective of heat application is to destroy pathogenic and spoilage microorganisms, and the hermetically sealing of the container prevents contamination by new microorganisms.

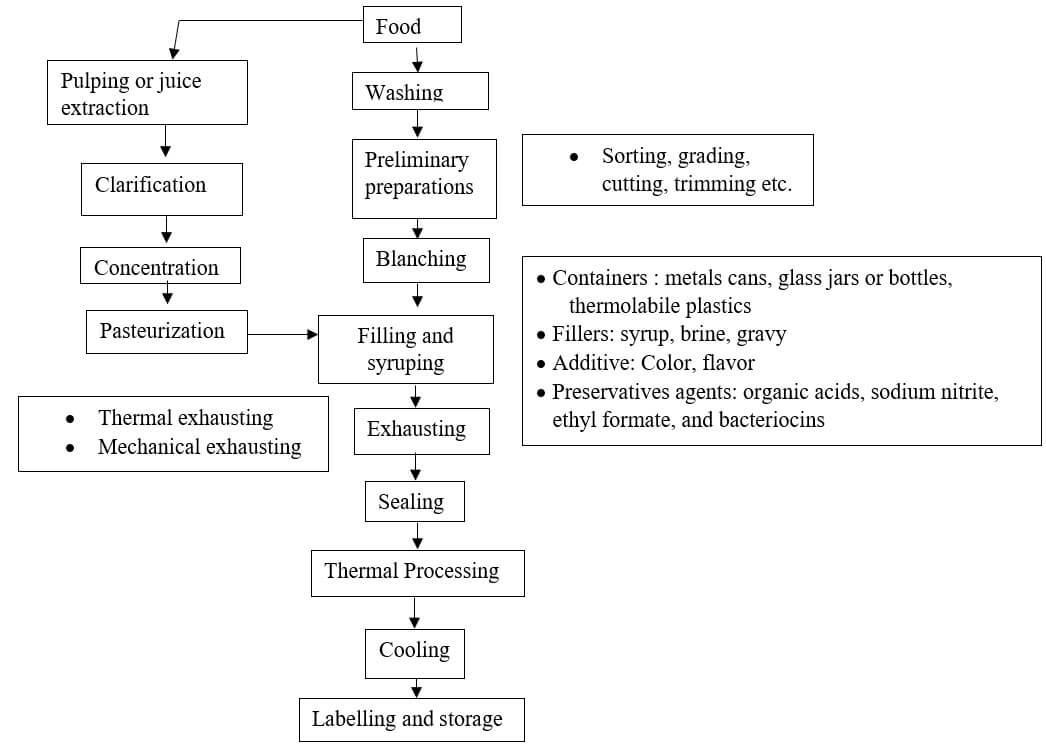

Steps of canning

1. Preparations

- The containers in which food is to be filled are preheated for sterilization.

- The preparation of food depends upon their types. The preparation of foods involves washing, trimming, sorting, grading, peeling, cutting, dicing, slicing, segmenting, pitting, and blanching according to their types.

2. Filling in the containers

- The food prepared is filled into the sterilized containers.

- The canned product is then filled with hot solutions of sugar syrup or fruit juices, brine with spices for vegetables, and gravy for meats.

- This process helps to add flavor and preservative agents, assist in further sterilization, and helps to remove the air space.

3. Exhausting

- The process of eliminating the air from the can before sealing is referred to as exhausting.

- Exhausting helps to prevent excessive pressure and stain during sterilization.

- Mainly, it prevents the bulging of a can and reduces the chemical reaction that occurs between the containers and the food contents.

4. Sealing

- After exhausting the can, it is immediately sealed.

- There are various types of sealing depending upon the product such as glass jars and bottles are sealed by screw type or crown capping machines, plastic pouches are sealed by dielectric or conduction heating.

- During sealing, the temperature of canned food must not be below 74°C.

5. Processing of the can

- The cans are heat-treated immediately after sealing at a suitable time and temperature.

- The main aim of can processing is to eliminate the microorganisms and their spores present without harming the nutritive quality of food.

- The heat is applied is usually above 100 °C (vegetative bacteria are killed at 80°/30min, spore-forming microorganism are killed at 110°C/30 min and the spores are destroyed at 121 °C/3 min).

6. Container cooling

- After processing, the cans are rapidly cooled to room temperature.

- It is either done by immersing the hot cans in cold water or by spraying with jets of cold water.

7. Labeling and storage

- The outer surface of the cans is dried for labeling after cooling.

- The label should carry product identification, brand name, net content by weight or volume, code number, name and address of the processor, list of ingredients, nutritional information, manufacture, and expiry dates.

- After labeling the can are stored in cool and dry places before dispatched.

Figure: Flowchart showing the canning process.

References

- Abdulhay, H. S. (2016). Detection of Microbial and Chemical Contamination in Canned Meat Available in Baghdad Local Markets. (May 2015).

- Evancho, G. M., Tortorelli, S., & Scott, V. N. (2009). Compendium of the Microbiological Spoilage of Foods and Beverages. In Compendium of the Microbiological Spoilage of Foods and Beverages. https://doi.org/10.1007/978-1-4419-0826-1

- Featherstone, S. (2015). Spoilage of canned foods. A Complete Course in Canning and Related Processes, 27–42. https://doi.org/10.1016/b978-0-85709-678-4.00002-6

- Food Microbiology, William C. Frazier; Fourth Edition.pdf. (1995).

- Jay, J. M. (2000). Modern food microbiology Sixth edition.

- Kempe, L. L., Graikoski, J. T., & Bonventre, P. F. (1958). Combined Irradiation-Heat Processing of Canned Foods II. J. Infectious Diseases, 124, 295–300. Retrieved from http://aem.asm.org/

- Kharel G.P., H. F. (2010). food preservation. Principle of Food Preservation, 466.

- Kumar, A. (2019). Food Preservation: Traditional and Modern Techniques. https://doi.org/10.31080/ASNH.2019.03.0529

- Lin, C.-C., Wu, B.-K., & Lin, D.-K. (1968). Spoilage Bacteria in Canned Foods I. Flat Sour Spoilage Bacteria in Canned Asparagus and the Thermal Death Time Downloaded from. In APPLIED MICROBIOLOGY. Retrieved from http://aem.asm.org/http://aem.asm.org/http://aem.asm.org/

- M. Shafiur Rahman Boca. (2007). Handbook of Food Preservation Second Edition.

- Osman Erkmen T. Faruk Bozoglu. (2016). Spoilage of Canned Foods. Food Microbiology: Principles into Practice, 376–384. https://doi.org/10.1002/9781119237860.ch22

- Ravishankar, S., & Maks, N. (2007). Basic Food Microbiology. Advances in Thermal and Non-Thermal Food Preservation, 1–31. https://doi.org/10.1002/9780470277898.ch1

- Vergara-Balderas, F. T. (2015). Canning: Process of Canning. In Encyclopedia of Food and Health (3rd ed.). https://doi.org/10.1016/B978-0-12-384947-2.00110-0