- Solid State Fermentation (SSF) is a fermentation method used by several industries like the pharmaceuticals, food, textile etc., to produce metabolites of microorganisms using solid support in place of the liquid medium.

- It is defined as the growth of microbes without free-flowing aqueous phase.

- The SSF is alternative to submerged fermentation for production of value-added products like antibiotics, single cell protein, PUFA’s, enzymes, organic acids, biopesticides, biofuel and aroma production.

- The support used is especially grain brans, de-oiled oil seed cakes, and other substances alike.

- Initially, mostly fungi were used in such fermentation (as these microorganisms were considered to be very optimally active in very low water activity). Later, many bacterial species and yeasts were used to carry out such fermentation also.

- The microbiological process of SSF has generated great interest in recent years because it can be used for a variety of purposes, supported by some authors who have even indicated numerous advantages over their liquid counterparts (submerged fermentation).

Interesting Science Videos

Solid State Fermentation (SSF) Substrate

- There are many biotechnological processes that involve the growth of organisms on solid substrates in the absence or near absence of free water.

- Solid state fermentation (SSF) deals with substrates that are solid and contain low moisture levels.

- The most regularly used solid substrates are cereal grains (rice, wheat, barley, and corn), legume seeds, wheat bran, lignocellulose materials such as straws, sawdust or wood shavings, and a wide range of plant and animal materials.

- Most of these compounds are polymeric molecules – insoluble or sparingly soluble in water – but most are cheap and easily obtainable and represent a concentrated source of nutrients for microbial growth.

SSF can be defined in terms of the following properties:

- A solid porous matrix which can be biodegradable or not, but with a large surface area per unit volume, in the range of 103 to 106 m2/ cm3, for a ready microbial growth on the solid/gas interface.

- The matrix should absorb water amounting to one or several times its dry weight with a relatively high water activity on the solid/gas interface in order to allow high rates of biochemical processes.

- Air mixture of oxygen with other gases and aerosols should flow under relatively low pressure and mix the fermenting mash.

- The solid/gas interface should be a good habitat for the fast development of specific cultures of molds, yeasts or bacteria, either in pure or mixed cultures.

- The mechanical properties of the solid matrix should stand compression or gentle stirring, as required for a given fermentation process. This requires small granular or fibrous particles, which do not tend to break or stick to each other.

- The solid matrix should not be contaminated by inhibitors of microbial activities and should be able to absorb or contain available microbial foodstuffs such as carbohydrates (cellulose, starch, sugars) nitrogen sources (ammonia, urea, peptides) and mineral salts.

Organisms Used in Solid State Fermentation (SSF)

- The microbiological components of SSF can occur as single pure cultures, mixed identifiable cultures or totally mixed indigenous microorganisms.

- Some SSF processes e.g., tempeh and ontjom production, requires selective growth of organisms such as molds that need low moisture levels to carry out fermentation with the help of extracellular enzymes secreted by fermenting microorganisms.

- However, bacteria and yeasts, which require higher moisture content for efficient fermentation, can also be used for SSF, but with a lower yield.

Steps in Solid State Fermentation (SSF)

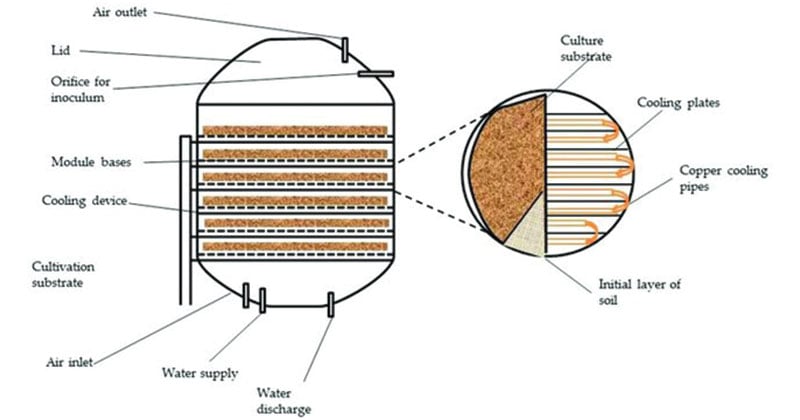

Figure: Schematic of solid state fermenter for conversion of lignocellulosic biomass to enzymes. Source: Amit K. Jaiswal.

SSF is normally multistep processes involving the following steps:

1. Pre-treatment of substrate raw materials either by mechanical, chemical or biochemical processing to enhance the availability of the bound nutrients and also to reduce the size of the components, e.g., pulverizing straw and shredding vegetable materials to optimize the physical aspects of the process. However, the cost of pre-treatment must be balanced with the eventual product value.

2. Hydrolysis of primarily polymeric substrates, e.g., polysaccharides and proteins.

3. Utilization (fermentation) of hydrolysis products.

4. Separation and purification of end products.

- The low moisture content of SSF enables a smaller reactor volume per substrate mass than LSF and also simplifies product recovery.

- However, serious problems arise with respect to mixing, heat exchange, oxygen transfer, moisture control and gradients of pH, nutrient and product as a consequence of the heterogeneity of the culture.

- The latter characteristic of SSF renders the measurement and control of the above-mentioned parameters difficult, laborious and often inaccurate, thereby limiting the industrial potential of this technology. Due to these problems, the micro-organisms that have been selected for SSF are more tolerant to a wide range of cultivation conditions.

Applications of Solid State Fermentation (SSF)

- Solid-state fermentation has emerged as a potential technology for the production of microbial products such as feed, fuel, food, industrial chemicals, and pharmaceutical products.

- It is widely applied to producing several enzymes, organic acids, flavoring compounds etc., which must be extracted and purified and then used in different products.

- Its application in bioprocesses such as bioleaching, bio-beneficiation, bioremediation, bio-pulping, etc. has offered several advantages.

Advantages of Solid State Fermentation (SSF)

- The main advantage of such methods is that it produces a minimum amount of waste and liquid effluent thus not very damaging to the environment.

- Solid substrate fermentation employs simple natural solids as the media.

- Low technology, low energy expenditure and requires less capital investment.

- No need for sterilization, less microbial contamination, and easy downstream processing.

- Utilization of agro-industrial residues as substrates in SSF processes provides an alternative avenue and value-addition to these otherwise under- or non-utilized residues.

- The yield of the products is reasonably high.

- Bioreactor design, aeration process, and effluent treatment are quite simple.

- Many domestic, industrial and agricultural wastes can be fruitfully used in SSF.

Limitations of Solid State Fermentation (SSF)

- The microorganisms that tolerate only low moisture content can be used.

- Precise monitoring of SSF (e.g., O2 and CO2 levels, moisture content) is not possible.

- The organisms grow slowly and consequently, there is a limitation in product formation.

- Heat production creates problems, and it is very difficult to regulate the growth environment.

References

- https://www.sciencedirect.com/science/article/pii/S1369703X02001213

- http://www.biologydiscussion.com/notes/short-notes-on-solid-substrate-fermentation/10044

- https://www.omicsonline.org/open-access/solid-state-fermentation-and-food-processing-a-short-review-2155-9600-1000453.php?aid=66522

- https://www.omicsonline.org/open-access/solid-state-fermentation-and-food-processing-a-short-review-2155-9600-1000453.php?aid=66522

- https://www.researchgate.net/publication/27205523_SolidState_Fermentation_An_Overview

- https://www.slideshare.net/ajithnandanam/solid-state-fermentation

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5428094/

- http://microbiology.ukzn.ac.za/Libraries/MICR304/SOLID_STATE_FERMENTATION.sflb.ashx

Good content Excellent

great

Examples biotechnology

used of fungi to production of cheeses

Biotechnology is a one of the subject of medical terms

It’s wonderful.