A magnetic stirrer is a laboratory device that employs a rotating magnetic field generated by a rotating magnet or stationary electromagnet to cause a stirrer bar immersed within a liquid to spin and thus quickly stir or mix the solution.

In 1917, Richard Stringham of Utah received a patent for the first magnetic stirrer. The magnets are rotated in the majority of modern magnetic stirrers by an electric motor. A coupled heating system for warming the liquid is typically part of a magnetic stirring system. Small volumes of low viscosity can usually be stirred with magnetic stirrers. Glass or other non-metallic beakers must be used with stirrers to avoid interference with the magnetic field. It is ideal for stirring in academic work, business, agriculture, health care, homebrewing, etc.

Interesting Science Videos

Principle of Magnetic Stirrer

The magnetic stirrer operates on the principles of attraction for opposite charges and repulsion for like charges. The stirring speed is adjustable, and it is frequently used to stir solvents of various viscosities. A micromotor powers a magnet to create a rotating magnetic field that rotates the stirring bar inside the vessel, enabling a thoroughly mixed reaction to take place. It is equipped with a temperature control system that can heat and regulate the sample’s temperature in accordance with experiment requirements, ensuring that the mixed liquid satisfies the experiment’s requirements while keeping the required temperature.

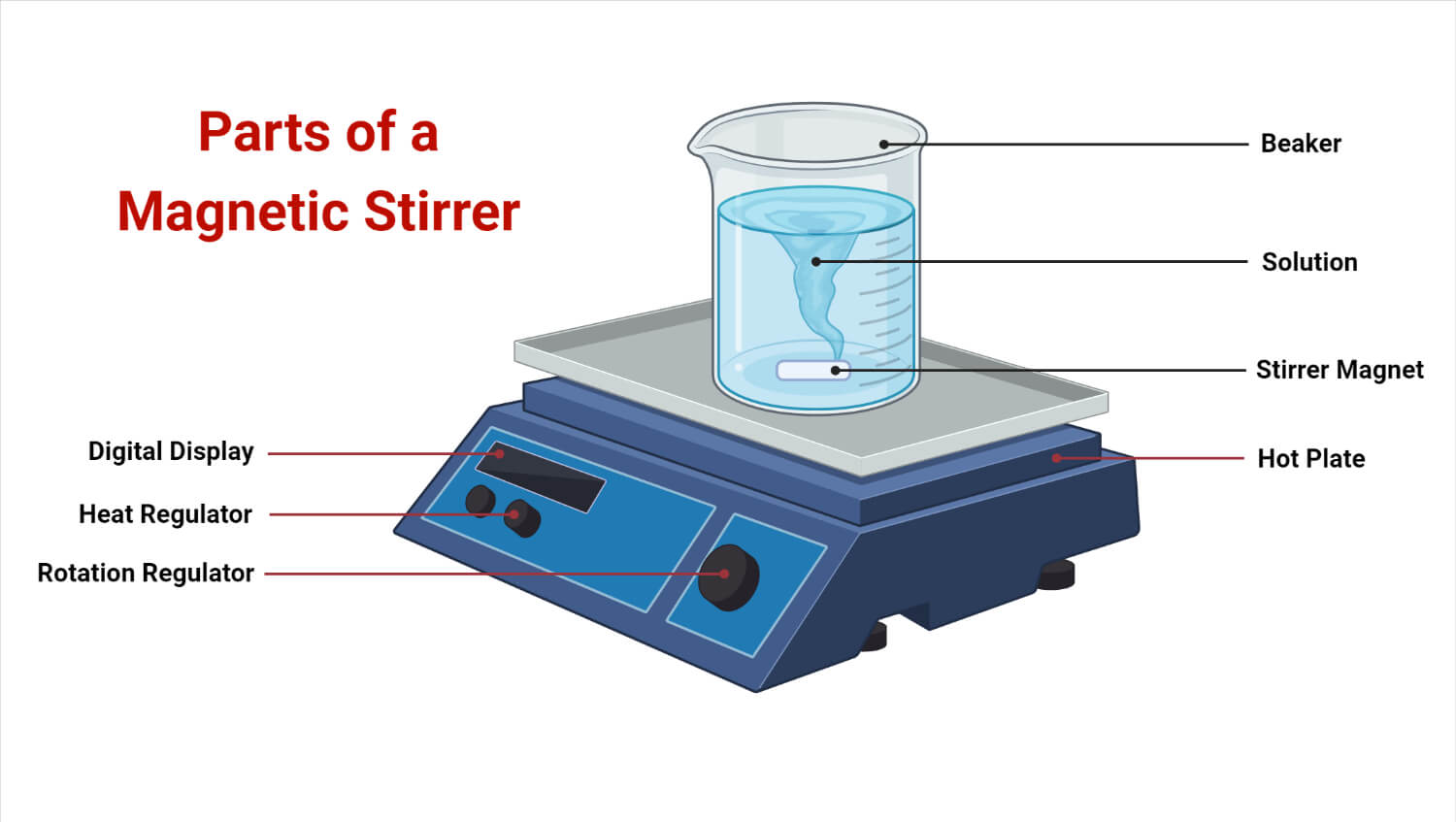

Parts of a Magnetic Stirrer

A stir bar and a hot plate stirrer are the two main parts of a magnetic stirrer. A stationary electromagnet, a hot plate, a temperature control knob, and a speed control knob are some of the additional components found inside a hot plate stirrer machine.

Top plate/Hot plate: Stainless steel or ceramic is typically used for the plates of magnetic stirrers. Ceramic: The white surface of ceramic top hotplates makes them suitable for titrations and other tasks requiring clear color vision. They also have high chemical resistance, making them ideal while working with corrosive chemicals that may splash onto the plate surface. Stainless steel: A stainless steel top plate offers a highly forceful coupling and stirring action since it does not produce eddy currents (like aluminum).

Stir bar: The term “stir bar” or “spin bar” refers to a tiny, Teflon-coated, white, rectangular magnet. The sole function of these bars is to stir solutions. They work in tandem with a stirring motor. The stir bar is put in a liquid-filled container, then placed over a stirring motor. The bar spins, and the liquid is stirred when the stir motor is turned on. The vessel shape and the viscosity of the stirring media determine the shape of the stir bar, which can be octagonal, circular, etc. The stir bar’s dimensions range from millimeters to a few centimeters.

Stationary electromagnet: It is positioned inside the stirrer instrument that helps to generate a magnetic field and rotate the magnetic needle (stir bar) immersed in liquid, thereby creating a high-speed stirring action enough to homogenize the mixture.

Speed controlling knob: The speed control knob is used to adjust the rotating speed (rpm) of the stir bar depending on the liquid’s density or project needs.

Temperature controlling knob: The magnetic stirrer features a knob for temperature control which controls the temperature based on the vessel size, the viscosity of the liquid, and its volume.

Stir bar retriever: These magnets are permanently embedded with PTFE (teflon) rod. It facilitates the safe and easy recovery of magnetic stirring and spin bars from irritant and corrosive liquid samples in glass flasks. However, it is less commonly employed in magnetic stirring.

Characteristics of Magnetic Stirrer

Capacity: Obviously, running water is rarely used for stirring. Therefore, the nominal capacity is significantly higher than the real capacity. A minimum of 1 liter of surfactant solution and roughly 250 ml of an emulsion can be accommodated in the micro models’ 3-liter capacities.

Maximum speed: The speed is measured in revolutions per minute (rpm) (rotations per minute). The speed is roughly 1000 rpm. Up to 2500 revs per minute are possible with strong versions.

Maximum permitted temperature and humidity: An individual should look at the instrument’s maximum allowable operating temperature and humidity while working in a wet lab, in a tropical area, or planning to mix hot materials.

Dimensions of the mounting surface: The size of beakers you can use with each magnetic stirrer is determined by the surface area.

The magnet: There are magnets in every size and shape imaginable, including basic rods and other geometric shapes like ellipses, discs, etc. The beaker must be compatible with the size of the stirring rod, typically 0.5–1.0 cm smaller than the beaker’s diameter. Undoubtedly, various magnetic rods are required while working with different beaker sizes.

Magnetic Stirrer operating procedure

- Prepare a container with the liquid solution already inside of it.

- The container should be placed on the hotplate.

- Connect to the mains to turn on the hotplate.

- By pressing the temperature setting button, adjust the hotplate’s temperature.

- Place the magnetic stir bar in a vessel filled with solution.

- Next, turn the stirrer magnetic speed adjustment button clockwise to change the speed of the magnetic stirrer. Turn the magnetic stirrer adjustment knob counter-clockwise if the stirring speed is too high.

- Stir the liquid mixture until uniformity is achieved.

- Remove the magnetic stirrer from the liquid solution container once done.

- Disconnect from the mains to turn off the hotplate.

- Use hot hands to lift the container.

Types of Magnetic Stirrers

The choice of size, configuration, and applications of magnetic stirrers are used to classify them. Some of the types of magnetic stirrers are as follows:

Magnetic Mini Stirrer

The laboratory magnetic stirrers for use in laboratories are compact and require less space. They have electronic controls that enable the user to precisely manage the speed. It can withstand destructive and corrosive substances in the lab. The speed regulator manages the rotation per minute (rpm) of the stirrer.

Magnetic Stirrer with Timer

The motor is automatically turned off after a certain time, thanks to a magnetic stirrer with a timer. A built-in timer will turn the stirrer off when the pre-selected duration of time has elapsed. Additionally, the speed is automatically decreased, and the weight is automatically removed.

Heavy-Duty Magnetic Stirrer

High mixing capacities are included with the heavy-duty magnetic stirrers. They are also very robust and exhibit good chemical resistance. They may be the ideal instrument for the lab to use for precise findings. The majority of chemical reactions require heated magnetic stirrers.

Battery Powered Magnetic Stirrer

They can be utilized in places with no electricity or other restricted environments. They are mostly used in incubators, operate on batteries, and have rubber feet to provide stability. They are portable and lightweight to carry.

Air-operated Turbine Magnetic Stirrer

The air-operated turbine magnetic stirrer is the ideal tool for blending liquids up to 1 liter of solution. A low-pressure air supply drives this magnetic stirrer. The crucial feature of this magnetic stirrer is that it eliminates the risk of sparking from electrical sources.

Applications of Magnetic Stirrer

- It is widely used in chemistry laboratories to perform chemical experiments and synthesis by mixing two or more components.

- It is used to prepare a medium to culture microorganisms in microbiology laboratories.

- It is used to prepare samples and perform analysis in chemistry and biology experiments.

- It is employed to achieve the maximum possible extraction efficiency from plant material by reducing organic solvent consumption.

- Other applications include oil analysis, soil suspending, buffer solutions preparation, pH measurement, etc., where it necessitates the blending of several types of liquids to achieve uniform mixing.

Advantages of Magnetic Stirrer

- It makes it possible to mix reagents at a constant temperature.

- In a sealed container, it prevents intense boiling from occurring.

- Both the response rate and the rate of evaporation are boosted.

- Long-lasting procedures like protein dialysis can be completed using it.

- Since only a little magnet bar that can be quickly cleaned and disinfected needs to be placed within the sample, there is no chance of contamination.

- Compared to electronic stirrers, they guarantee excellent productivity and precision and are quiet and simple to use.

- The stir bar can mix up to one liter of liquid and rotates at different speeds.

- The samples might be blended for several hours or even overnight.

- The lack of moving external parts results in no breakage and wear out.

- It has a compact size and occupies a small space.

Limitations of Magnetic Stirrer

- It is ineffective for dispersing nanoparticles. Sonication-coupled magnetic stirring is used for dispersing nanotubes.

- Viscous liquids or thick suspensions are difficult to deal with magnetic stirrers.

- Due to the limited size of stir bars, magnetic stirrers are only suitable for relatively small experiments (under 4 liters).

Precautions

- To prevent mishaps, the instrument housing needs to be correctly grounded.

- To avoid excessive vibration during operation, the medium-speed operation can run continuously for eight hours, and the high-speed operation can run continuously for four hours.

- To prevent harm to the instrument, keep it dry and clean, forbid solution from entering it, and turn off the power when not in use.

- Turn off the power and keep items in a dry, ventilated area when not in use for an extended time.

- Stirring heating time should not be lengthy; occasional use can extend the life.

- If a stirrer is beating or not stirring while mixing, slow it down or turn off the power to verify if the location is correct and the beaker’s bottom is flat.

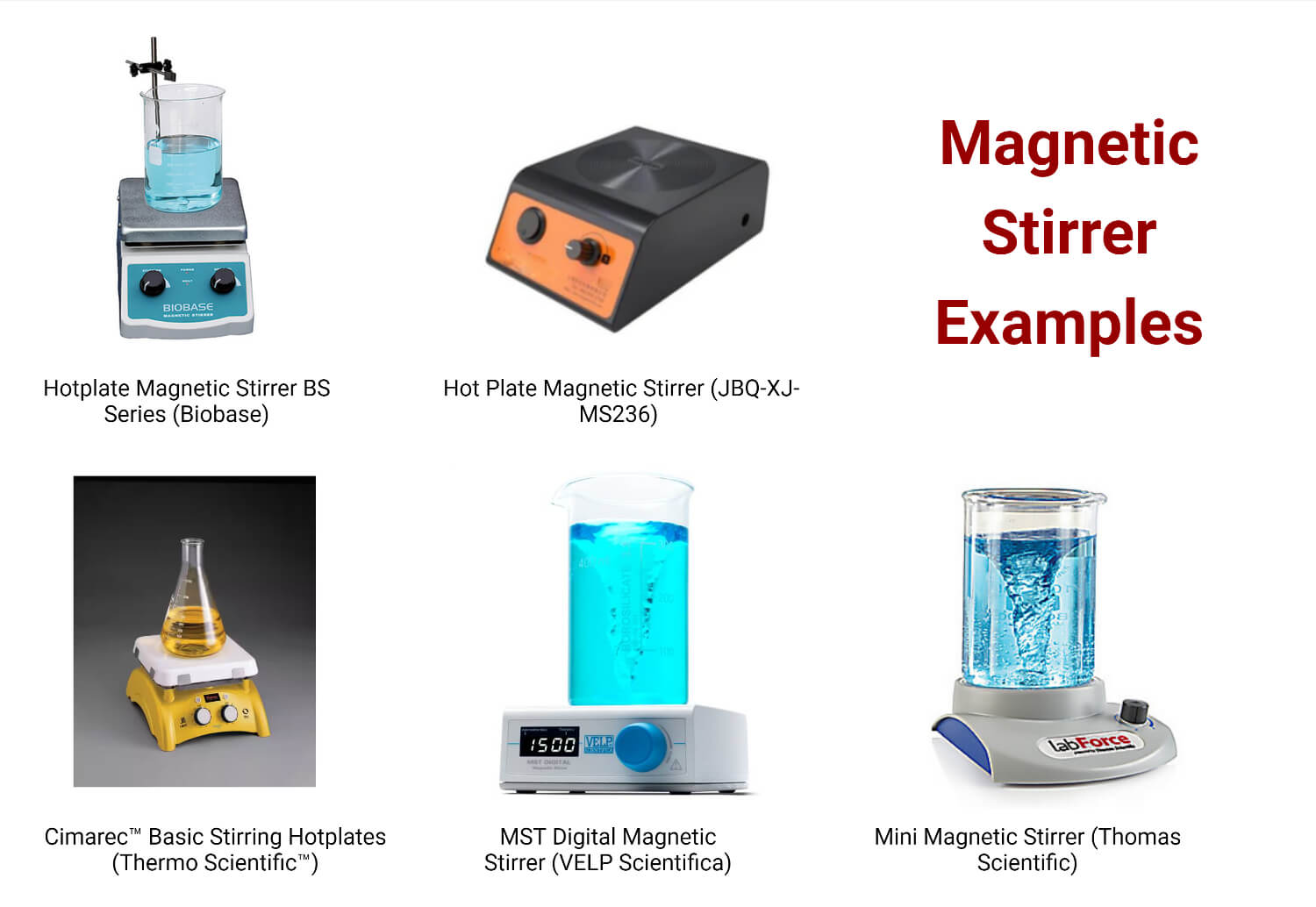

Magnetic Stirrer Examples

Hotplate Magnetic Stirrer BS series (Biobase)

- Stirring and heating can both happen at the same time.

- Steplessly adjustable stirring and heating power.

- Maximum temperature: 380°C and maximum speed: 2000 rpm

Mini Magnetic Stirrer (Thomas Scientific)

- It is portable and lightweight, and the small footprint frees up important benchtop space.

- The small stirrer’s quiet operation and minimal vibration aid in user concentration by lowering lab noise.

- Ideal for regular stirring tasks in lab environments for general research, life science, industry, quality analysis, and clinical care.

Magnetic Stirrer JBQ-XJ-MS236 (Biometer)

- Its use is straightforward and practical.

- The knob operation, changeable mixing speed, and uniform mixing support variable experimental applications.

- Built-in lithium battery with a big capacity provides a minimum battery life of 48 hours, making it practical for mobile use across many industries.

Magnetic laboratory stirrer Cimerac™ Basic (Thermo Scientific)

- Basic Cimarec stirrers from Thermo Scientific are ideal for everyday usage and at a low cost.

- It can stir at rates between 100 and 2500 rpm.

- For precisely adjusting speed, the stirrer incorporates control knobs. Its redesigned top-plate design lessens the possibility of breaking.

- Additionally, the spillway design prevents internal parts from being harmed by spills.

- A 1.3 cm diameter support rod can fit in its built-in ring-stand holder.

Magnetic laboratory stirrer MST (VELP Scientifica)

- Strong, small, and versatile

- Featuring a brushless motor

- Techno-polymer ensures great chemical resistance.

- Accepts a flask of up to 5 liters

- Built with the longest longevity in mind and backed by a three-year warranty

- Ideal for microtitration, BOD, microbiology, and biochemistry; it stays cool even after hours of continuous use.

References

- https://camblab.info/a-guide-to-different-types-of-stirrers/

- http://www.lanphan.com/lab-instruments/How-Does-a-Magnetic-Stirrer-Work-414.html

- https://microbeonline.com/magnetic-stirrer-parts-principle-and-types/

- https://orgchemboulder.com/Technique/Equipment/Benchequip/Stirbar.shtml

- https://www.kewlab.com/blog/post/magnetic-stirrer-working-principle-and-uses

- https://www.dwkltd.com/en/azlon-magnetic-stirrer-bar-retriever-ptfe-1

- https://www.scienceequip.com.au/blogs/news/magnetic-stirrers-uses-types

- Hingmire Yashashri, R., Javalgikar Akshay, S., & Mane Laxmi, B. (2017). Application of magnetic stirrer for influencing extraction method on Tectona grandis as analgesic activity. Int J Pharm Clin Res, 9, 634-637.

- https://www.pce-instruments.com/f/english/media/magnetic-stirrer-introduction.pdf

- https://www.exposedmagazine.co.uk/features/what-is-a-magnetic-stirrer-types-and-function/

- https://www.alphapedia.net/magnetic-stirrer/

- https://matob.web.id/random/science/what-is-magnetic-stirrer-and-its-function/

- https://www.thomassci.com/Equipment/Magnetic-Stirrers/_/Mini-Magnetic-Stirrer-1?q=Mini%20Magnetic%20Stirrer

- https://www.biobase.com/product/hotplate-magnetic-stirrer

- https://www.medicalexpo.com/prod/thermo-scientific/product-78678-507120.html

- https://www.medicalexpo.com/prod/velp-scientifica/product-98393-768228.html

- Samsuri, S., Li, T., Ruslan, M.S., & Amran, N.A. (2020). Antioxidant Recovery from Pomegranate Peel Waste by Integrating Maceration and Freeze Concentration Technology. International Journal of Food Engineering, 16.