In microbiology, inoculation is the process of adding bacteria to a culture media so they can reproduce there. To increase immunity against a certain disease, it is frequently used to introduce vaccines, serum, or other antigenic substances into the body.

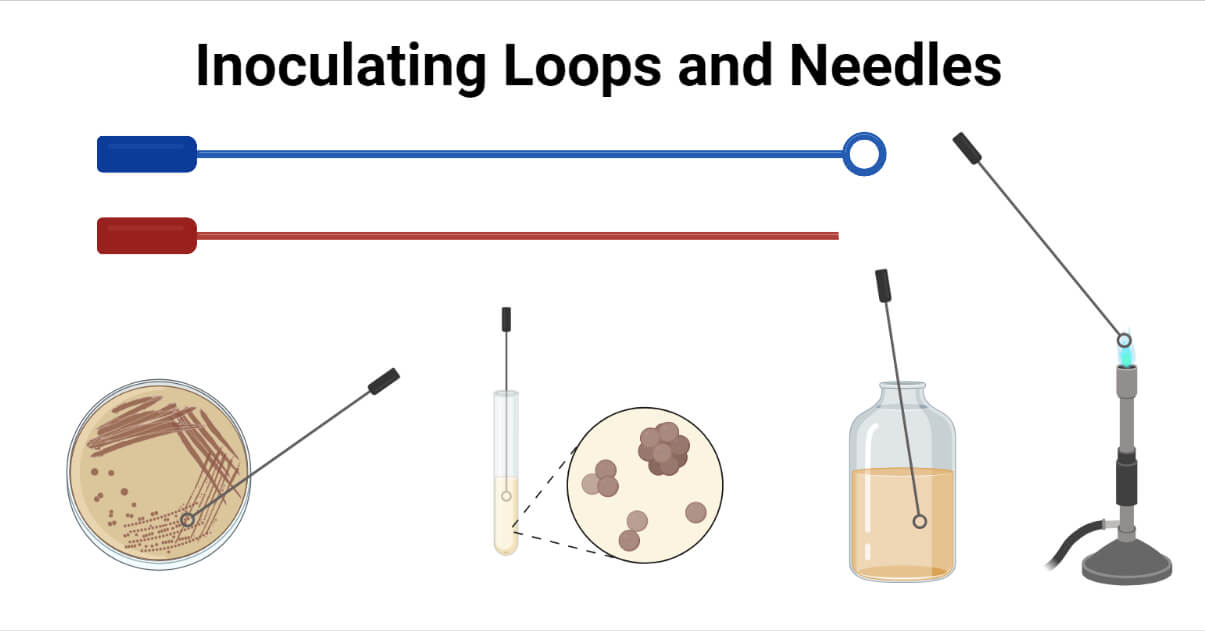

Inoculating loops and needles are hand-held and compact appliances that introduce microorganisms like bacteria or yeast into plated or tubed growth media before incubation, multiplication, or growth. The inoculum is commonly delivered and disseminated into liquid media, streaked onto or stabbed into a solid agar-based medium, or both.

An inoculation loop often referred to as a smear loop, inoculation wand, or microstreaker, is a basic instrument used largely by microbiologists to take and transfer a small sample (inoculum) of a microbe culture, for instance, to strip on a culture plate. It is a tool often constructed of nichrome or platinum wire, with a tip with a tiny loop with a diameter of around 2 mm to 5 mm. Transferring liquid media between Petri plates or liquid media requires loops. The liquid media are retrieved via an inoculation loop. Loop wires can also extract larger samples.

Needles transfer solid media between Petri plates or other solid media. When removing solid or dense material, an inoculation needle is employed. These work well for removing samples of small colonies of microscopic organisms.

These are employed for sampling and transmitting small amounts of microorganisms before additional investigation, microscopic examination, or serial dilution.

Interesting Science Videos

Principle of Inoculating Loops and Needles

Flaming of the loops and needles till they become red hot facilitates their sterilization such that it prevents cross-contamination of samples. Following this, when they are cooled, they are ready to pick up, transfer and inoculate the microbial sample into the media or prepare a smear.

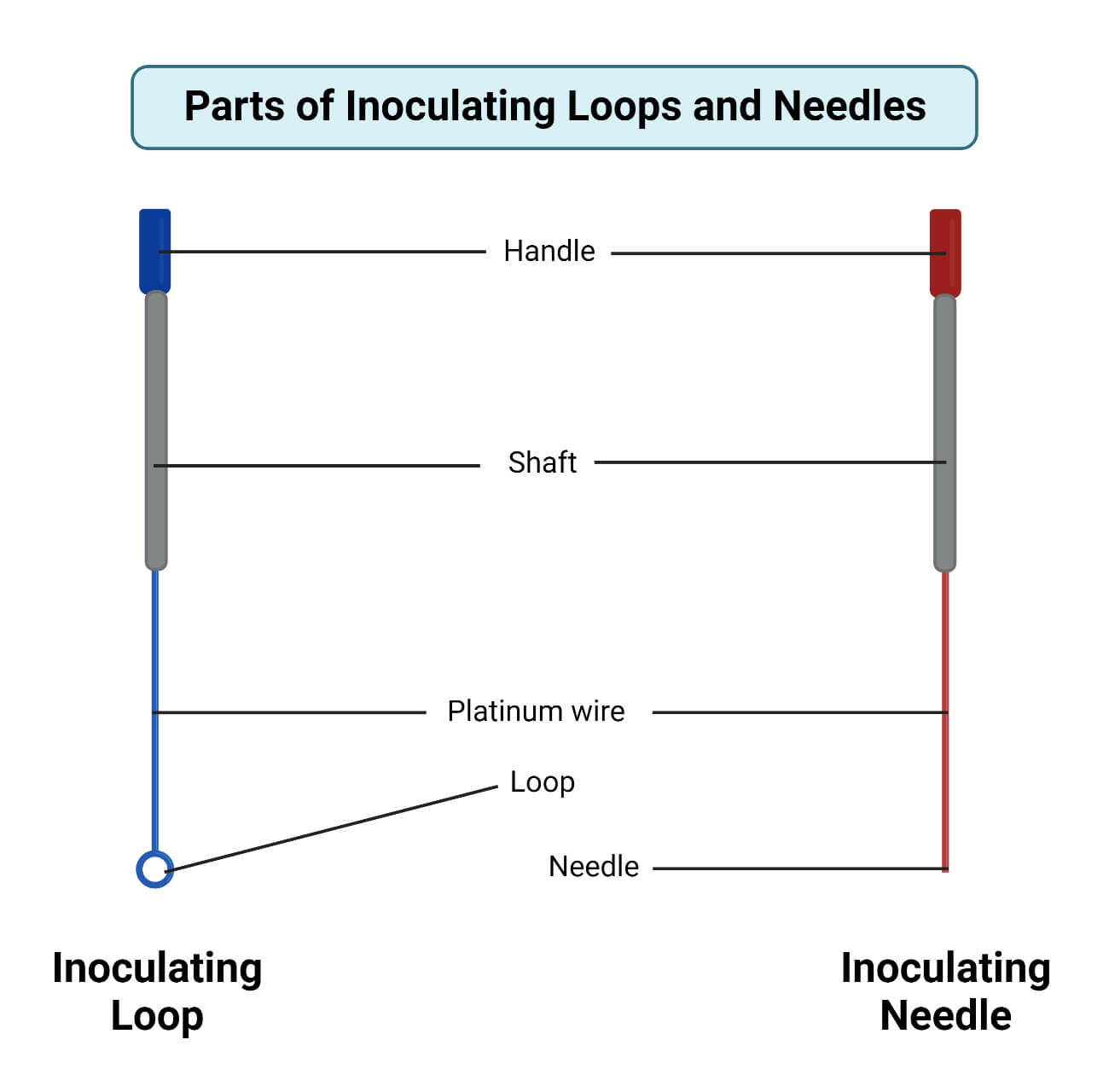

Parts of Inoculating Loops and Needles

- Handle: The inoculating loop or needles are handled by holding the handle part of the loop or needle and facilitating fatigue-free application. It is made of aluminum and brass in either an insulated or non-insulated format. The handle is 8 inches long.

- Shaft: Nickel-plated brass is used to make the loop shaft. For added heat protection for the user, PVC is used to insulate the shaft of the loop handle.

- Turret: It holds nickel-chromium or platinum wire.

- Loop: The nichrome or platinum wire affixed to the turret is twisted into a loop structure at the end. The wire is resistant to high temperatures and oxidation. The loop is 2mm to 5 mm in diameter.

- Needle: It is substantially identical to the loop but uses a straight wire instead.

Types of Inoculating Loops and Needles

There are mainly two types of inoculation loops, namely:

- With calibrated inoculation loop (Calibrated)

- It is employed for quantitative specimen cultures.

- It is available in sizes of 1µL and 10µL.

- Licensed calibration.

- Without calibrated inoculation loop (Noncalibrated)

- Various sizes are available with an internal diameter (Ø) of 2, 3, 4, or 5 mm.

- It is simple to use and dispose of.

- Inoculation loops are ready to use.

- It has undergone gamma radiation sterilization.

Inoculation needles are categorized as reusable and disposable based on their durability.

- Reusable inoculation needle: A metallic handle and nichrome or platinum wire are attached to form the common reusable inoculation needle.

- Disposable inoculation needle: It is usually composed of plastic resin. A blunted end is formed by the dulling of the needle’s base. These are employed in environments where the flame is impractical, such as under hoods and in anaerobic chambers, thereby removing the risk of infection from pathogens spread via aerosol generation, cross-contamination, spattering, and risks associated with open flames, and are color coded for easy identification. It is rigid enough to permeate the media for subsurface inoculation.

Inoculating Loops and Needles Operating Procedure

- Sterilize the wire inoculating loop by angling through the heat source until the full length of the wire begins to glow red/orange from the heat.

- Cool the loop or needle before selecting the bacterial sample to be transferred.

- The loop/needle is reheated after use to sterilize it.

- Disinfect a 12-inch diameter ring around the base of the heating device to eliminate any bacteria that survived the heating process.

Applications of Inoculating Loops and Needles

- Inoculating needles are used in microbiology to investigate bacteria and fungi on semi-solid media.

- Needle-oriented culture techniques are also used in biotechnology, cell biology, and immunology.

- The inoculation loop/ needle is used for streak plate streaking, fishtail inoculating slant cultures, and inoculating stab cultures.

- Stab cultures are used to research cell motility, microbial oxygen requirements utilizing thioglycolate cultures, and the gelatin liquefaction of bacteria. Stab cultures especially call for the inoculation needle.

- Inoculating loops and needles are employed for inoculation, serial dilution, sterile sampling, transfer, and spreading microbiological samples.

Advantages of Inoculating Loops and Needles

- The use of platinum wire in inoculating loops and needles facilitates their rapid heating and rapid cooling such that it saves time as well as increases the efficiency of work.

- Likewise, nickel-chrome loops possess durability and rapid cooling following heat sterilization.

- Disposable inoculating loops and needles do not require flaming and thus eliminate the risk of infection due to the aerosol formation of pathogenic microorganisms.

Limitations of Inoculating Loops and Needles

- Platinum wires are costlier. Disposable plastic loops and needles are also quite expensive.

- This process of inoculating is time-consuming, and the integrity of samples can be damaged if mistakes are made.

- There is a high potential for human error and contamination while working with multiple samples.

Precautions

- The region around the heating device should be disinfected after the completion of the heating process to eradicate the microorganisms that survived following flaming.

- The heated loop or needle should not be touched with the hand after flaming, and let it cool down for some time before use. Hot loops and needles kill the sample microorganisms to be transferred.

- The wire loops and needles should be flamed before and after use.

- Streaking should be performed gently with smooth and rapid movements to prevent gouging the agar plate.

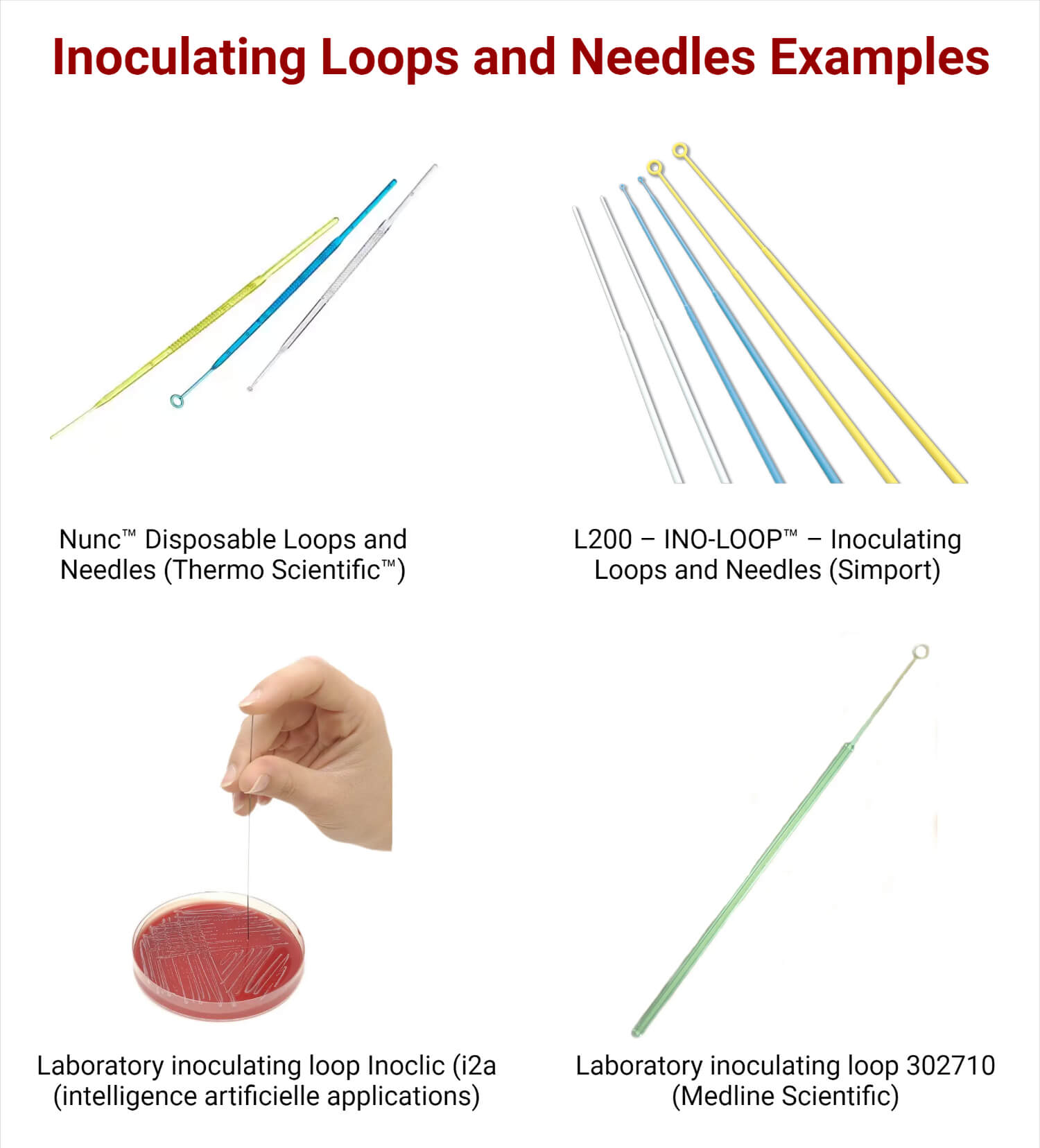

Inoculating Loops and Needles Examples

Laboratory inoculating loop Nunc™ (Thermo Scientific)

- Nunc loops and needles from Thermo Scientific are disposable.

- They are constructed from non-toxic polystyrene.

- Due to liquid adherence characteristics, accidental discharges are avoided.

- Precision-molded, these items can be applied to a wide range of fields, including biotechnology, pharmaceuticals, research labs, and the manufacture of diagnostic kits and vaccines.

Laboratory inoculating loop L200 Ino-Loop™ (Simport Scientific)

- Smooth and flexible loops and needles allow uniform streaking without harming the gel’s surface.

- Sterilized and contained in secure, tamper-evident zip-lock resealable bags.

- Cross-contamination brought on by insufficient sterilization is eradicated.

Laboratory inoculating loop Inoclic (i2a (intelligence artificielle applications) S.A.)

- INOCLIC is advised for the suspension of bacteria in a liquid medium or the inoculation of agar or tubed maintenance media.

- INOCLIC can launch identification using the same agar plate by using mass spectrometry and AST on agar media.

Laboratory inoculating loop 302715 (Medline Scientific)

- They provide uniform and clean streaking while protecting the gel surface because they are smooth and flexible.

- They come in handy sterile peel pouch packs marked with the batch and expiration date.

References

- https://www.clinisciences.com/en/buy/cat-inoculating-loops-and-needles-for-5565.html

- https://pharmaceuticalmicrobiologi.blogspot.com/2016/12/inoculation-loop.html

- https://www.slideshare.net/vidhyakalaivani29/inoculation-loop

- https://www.fishersci.fi/fi/en/products/I9C8L41A/inoculating-loops-needles.html

- https://www.fishersci.com/shop/products/fisherbrand-disposable-inoculating-loops-needles-6/p-3622181#?keyword=

- http://site.iugaza.edu.ps/aqabbas/files/general-micro.pdf

- https://www.linkedin.com/pulse/optimal-use-inoculating-loop-microbiology-drtvrao-md-dr-t-v-rao/

- https://www.medicalexpo.com/prod/thermo-scientific/product-78678-507212.html

- https://www.medicalexpo.com/prod/simport-scientific/product-70088-886629.html

- https://www.medicalexpo.com/prod/i2a-intelligence-artificielle-applications-sa/product-107407-1047652.html

- https://www.medicalexpo.com/prod/medline-scientific/product-76782-1051786.html