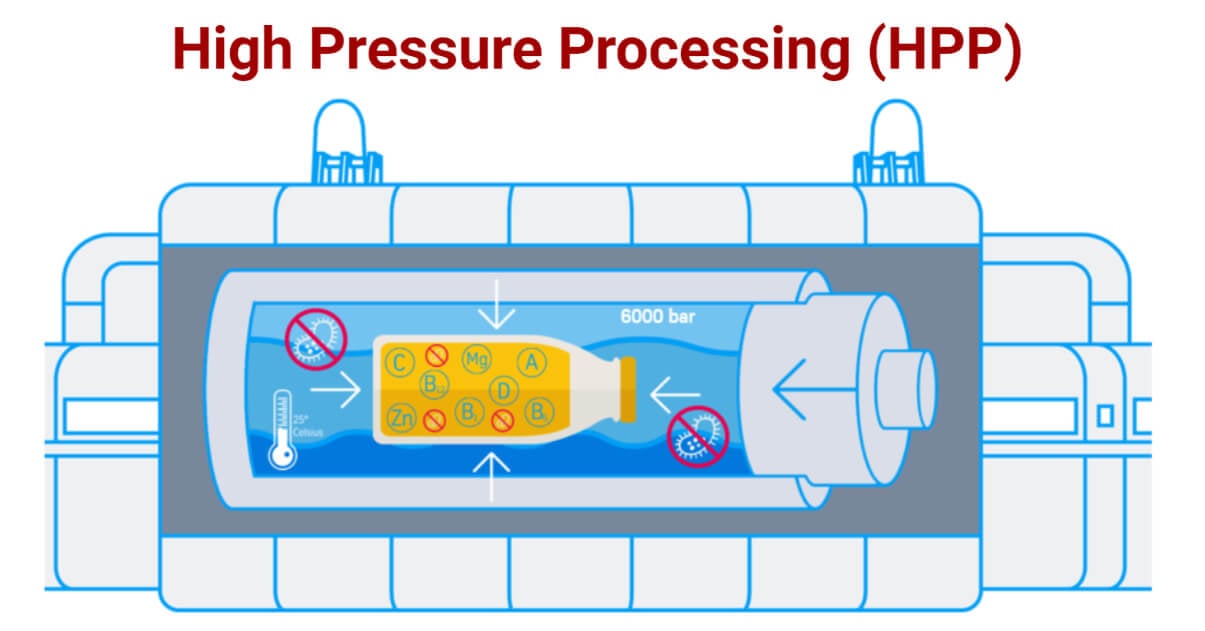

High-pressure processing (HPP) is a novel food preservation technology in which food is subjected to a pressure ranging between 40 and 1000 Mpa for a certain period (milliseconds to minutes) under the specified processing temperature from below 0°C to above 100°C to achieve microbial inactivation or to alter the food attributes to achieve desired food characteristics. (1 Mpa is equal to 145.03 Psi or 10 Bar).

It can also be termed high hydrostatic pressure (HPP) or ultrahigh-pressure (UHP) processing.

Interesting Science Videos

Principle of High-Pressure Processing (HPP)

High-pressure processing (HPP) is based on the Le Chatelier principle; “Whenever pressure is applied to a system in equilibrium, the system will react to counteract the effect of constraint”, such reaction will decrease volume under the high pressure and result in inactivation of microorganisms and enzymes.

Isostatic processing is another fundamental principle of HPP technology. It states, “When the food product is compressed by uniform pressure from every direction, it will return to its original shape when pressure is released.”

Microorganisms, chemical, biochemical and enzymatic reactions, as well as functional properties of biomolecules, are affected by high pressure.

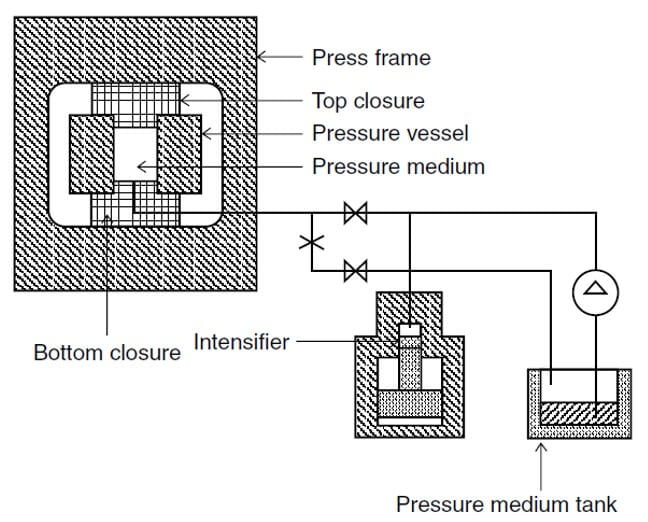

Equipment of High-Pressure Processing (HPP)

There are two types of compression setups for HPP according to the pressure generation module:

- Direct compression HPP

- In this setup, pressure is generated by moving a small diameter piston by hydraulic pressure, reducing the volume.

- Fast compression

- But requires a high-pressure dynamic seal between the piston and the internal vessel surface.

- Applicable to laboratory or pilot plant systems

- Indirect compression HPP

- This compression system uses a high-pressure intensifier to pump the desired pressure from a reservoir into a closed high-pressure vessel.

- It is applicable to a commercial scale.

The main components of high-pressure process systems are:

- A High-pressure vessel and its closure

- Pressurizing system

- Heating and cooling system

- Materials handling system

- Data generation system; microprocessor controller

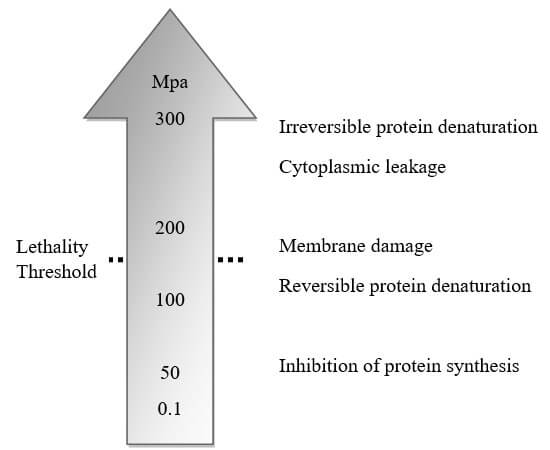

Effect of High-pressure on Microorganisms

- Pressure sensitivity varies with the type of microorganism; food poisoning or food spoilage, forms of microorganisms; vegetative or spore form.

- Gram-positive bacteria are more resistant to pressure than gram-negative bacteria due to teichoic acid.

- Spores are more resistant to pressure than vegetative form because spore contains calcium-rich dipicolinic acid, which protects from excessive ionization.

Effect of pressure on microbial lethality:

Types of bacteria and HP processing conditions

| S.N. | Bacteria | Processing conditions |

| 1. | Vegetative form | 400-600 Mpa |

| 2. | Spore form | More than 1000 Mpa |

| 3. | Staphylococcus | More than 500 Mpa for more than 60 minutes |

| 4. | Escherichia coli | 6 log cycle reduction at 405 Mpa for 10 minutes |

| 5. | Saccharomyces cerevisiae | More than 6 log cycle reduction at 405 Mpa for 10 minutes |

| 6. | Bacillus cereus spore | More than 800 Mpa |

| 7. | Vibrio parahaemolyticus | 6 log reduction at 200 Mpa for 20 minutes |

| 8. | Listeria monocytogenes | 340 Mpa for 20 minutes |

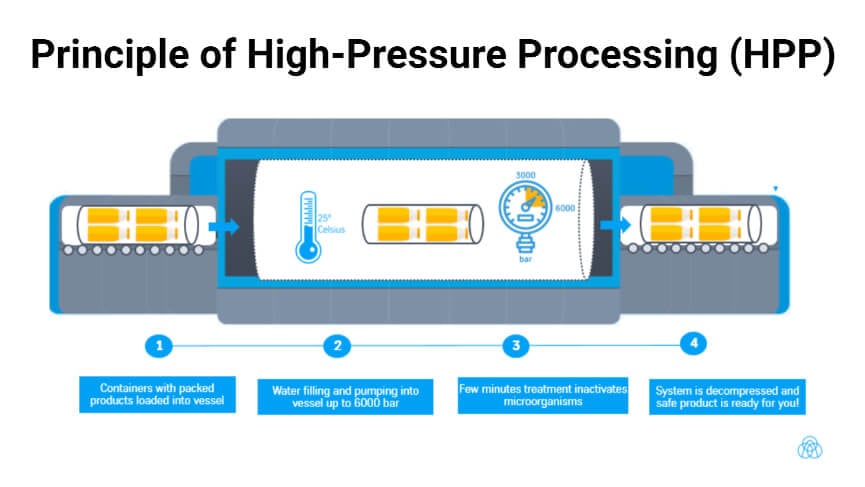

Working mechanism of High-Pressure Processing (HPP)

- Food type:

- The food product is packaged in a flexible container (plastic pouch or bottle) and sealed.

- Ethylene-vinyl alcohol copolymer (EVOH) and polyvinyl alcohol (PVOH) are recommended for food packaging.

- Loaded into the high-pressure chamber filled with pressure-transmitting fluid for pressurizing.

- Deaeration using the pump.

- Pressure is generated in the system using a pump and pressure is applied to the desired level for a specific time.

- The product is removed from the setup and stored properly.

Processing parameters

- The cost of operation depends on the time of exposure, processing temperature, and processing pressure.

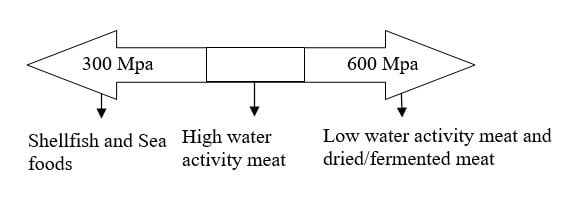

- The range of processing pressure depends on the water activity and types of food products.

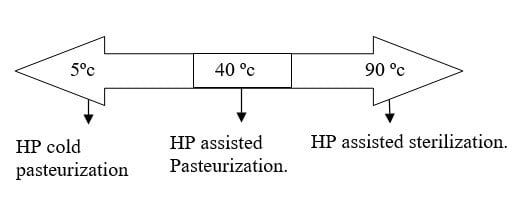

While Processing temperature depends on the objective.

- HP cold pasteurization or HP-LT aims to inactivate vegetative pathogenic bacteria.

- HP-assisted pasteurization and HP-assisted sterilizations aim to sterilize low-acid foods and to inactivate bacterial spores.

- Holding time in the pressure vessel depends on the type of food matrix and processing temperature.

- Optimization of HPP is directly related to the targeted pathogenic and spoilage bacteria.

- The operation can be carried out in batch or semi-continuous mode for commercial application.

- In batch processing, prepacked foods are loaded in a processing vessel, whereas semi-continuous processing pumpable products are used.

- Industrial HPP is typically carried out in batch processing mode.

High-pressure processing system

On the basis of orientation, HPP system are of two types;

- Horizontal HPP system

- Vertical HPP system

Uses of High-Pressure Processing (HPP)

- Pathogen elimination

- Shelf-life extension

- Innovative fresh products

- Increased shellfish yields

- Reduced sodium products

- Clean-label products

- Convenience

Application of High-Pressure Processing (HPP) and some examples

| S.N. | Food product | Processing condition | Package |

| 1. | Jams, fruit sauces, fruit jellies, yogurts | 400 Mpa, 20ºC, 10-30 min | Plastic cup |

| 2. | Grapefruit juices | 120-400 Mpa, 20ºC, 2-20 min | Glass bottle |

| 3. | Tropical fruits | 50-200 Mpa | Paper cups |

| 4. | Beef | 100-250 Mpa, 20ºC, 30 min to hrs. | |

| 5. | Rice cake | 400 Mpa, 45-70ºC, 10 min |

References

- Potter NP (1987), Food Science, CBS Pub, India

- Rahman MS (1999), Handbook of Food Preservation, Marcel Dekker, Inc, NY

- Desrosier EN (1963), The Technology of Food Preservation, AVI Publishing Company, New York

- High Pressure Processing for the Foods sector. High hyrostatic – Laboratory, R&D and Production systems. (highpressurefoodprocessor.com)