Biosafety cabinets or Biological Safety Cabinets (BSCs) are also called Microbiological Safety Cabinets. These enclosed containments feature a well-ventilated hood and are intended to safeguard personnel, products, and the environment from hazardous particulates and infectious agents.

- It is sometimes referred to as a tissue culture hood or a laminar flow hood. Laminar flow resembles a biosafety cabinet; however, it differs because a laminar hood is only concerned with the protection of the sample product, not the personnel and the environment.

- It maintains the standard or controls the quality of the item being worked with. The materials could potentially be contaminated with pathogens.

- It is the primary barrier protection that shields individuals and the environment from aerosols or droplets that might disseminate biohazardous substances.

- An efficient containment system for safely handling low, moderate, and high-risk pathogens (Risk Groups 1-3) is provided by well-maintained BSCs when used in concert with sound microbiological techniques. Thus, to ensure they work effectively and offer essential protection to people, products, and the environment, BSCs need routine maintenance by qualified specialists.

BSCs offer three levels of protection:

- Personnel- HEPA filters and an air curtain shield users from biohazardous aerosols produced inside the chamber.

- Sample Protection- Recirculating and unidirectional HEPA-filtered air guards against contamination of samples by contaminated lab air.

- Lab/ Environmental Protection- HEPA-filtered exhaust from the top of the cabinet safeguards against contaminating the lab environment with biohazardous aerosols inside the chamber.

Interesting Science Videos

Classes of Biological Safety Cabinets

There are three classes of biosafety cabinets:

- Class I BSC,

- Class II BSC, and

- Class III BSC

Class I only offers personnel and environmental protection, while Class II and III mediate protection to all three levels: personnel, environment, and product. All classes of biological safety cabinets share a common component which is the high-efficiency particulate air (HEPA) filter. This filter eliminates 0.3 micron-sized particles, which include every type of bacteria, spore, and virus, with a 99.97% effectiveness from the cabinet’s interior. It does not, however, eliminate gases or vapors.

A. Class I Biosafety Cabinet

- It is the most basic, fundamental, rudimentary, and elementary category of safety cabinets.

- Its sole objective is to make the protection of personnel and the environment possible effectively and cost-effectively.

- It operates with an open front and has negative pressure ventilation.

- Either the lab or the outside receives the air exhaust from the cabinet.

- These cabinets are either ducted i.e. connected to the building exhaust system or unducted i.e. recirculating filtered exhaust back into the laboratory.

- There is no defense against contamination or the sample being manipulated.

- Biological material from Risk Groups 1, 2, and 3 (RG1, RG2, and RG3, respectively) can be handled.

- Class I BSCs shouldn’t be utilized with research materials (like cell lines) that must be dealt with under sterile conditions because the incoming air is not filtered.

- Class I cabinets can be used safely with agents requiring Biosafety Level 1, 2, or 3 containments.

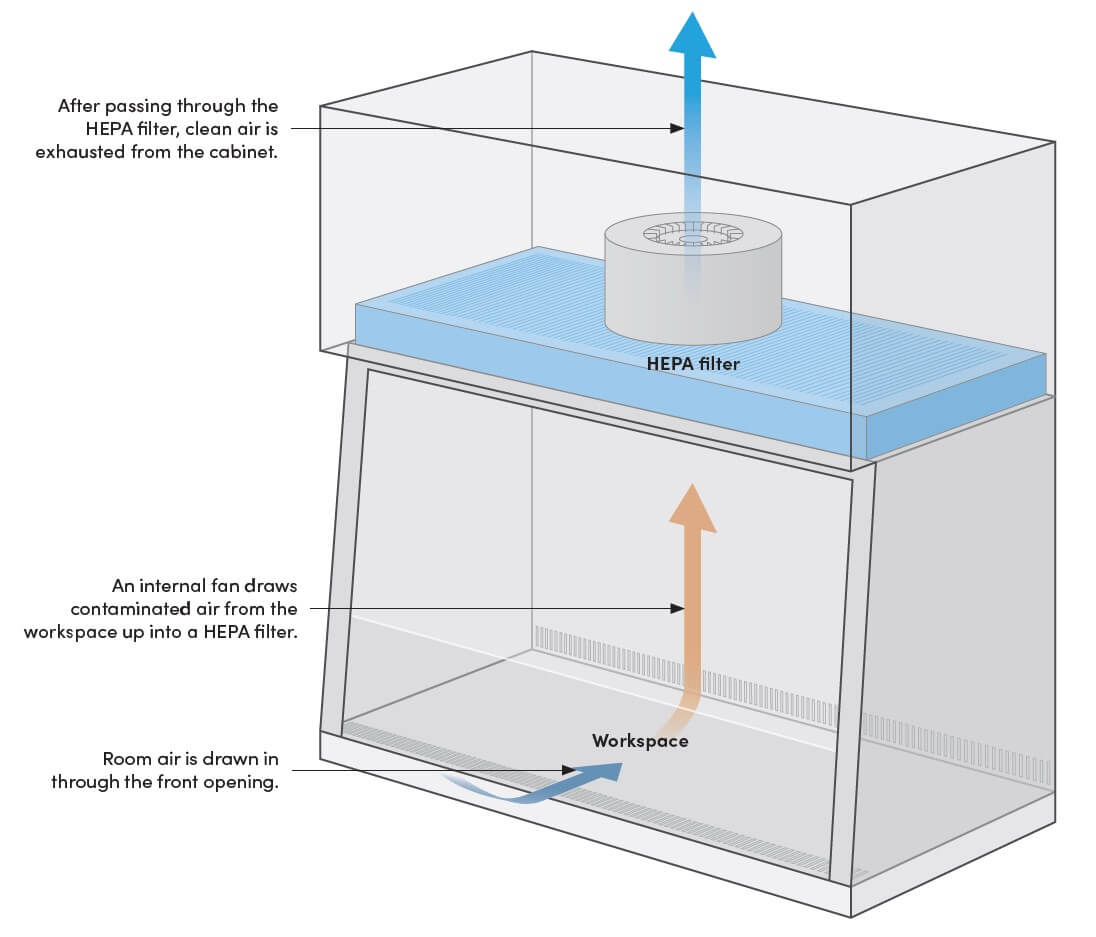

Working Mechanism of Class I Biosafety Cabinet

An airflow with a minimum velocity of 0.38 m/s enters the cabinet through the front entrance. It moves over the workspace before exiting the cabinet through an exhaust duct. The stream of inward air transported out all the aerosols produced during work during microbiological manipulations. As soon as it goes through the filtration system, the air is released from the cabinet with clean, contaminant-free air, trapping all airborne particles and pollutants. HEPA (High-Efficiency Particulate Air) filter and pre-filter make up the filtration system.

Features of Class I Biosafety Cabinet

- Front opening

- Exhaust Plenum

- Exhaust HEPA filter

- Sash

Uses of Class I Biosafety Cabinet

- In an animal lab for cage dumping

- Aerate cultures that potentially produce aerosols

- It is only employed in low- and moderate-risk microbiological studies.

- Fermenters and centrifuge housing

B. Class II Biosafety Cabinet

- A Class II Biosafety Cabinet protects people, the environment, and the product.

- It is frequently observed in clinical, life science, hospitals, pharmaceuticals, and research labs that operate with tissue culture or infectious agents in Risk Groups 2, 3, and 4 (if positive-pressure suits are worn).

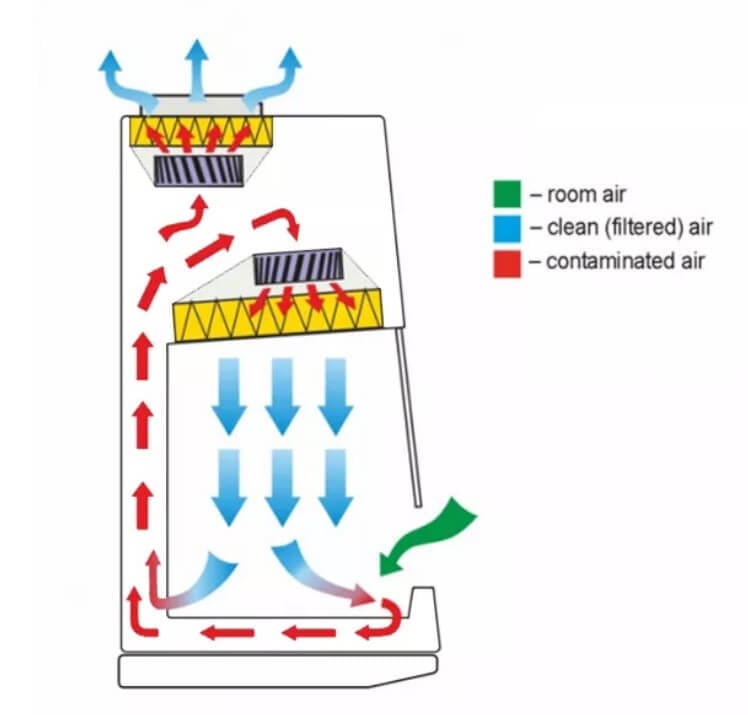

- Class II is comparable to Class I in that it employs negative pressure to stop air from passing through an access panel and a supply aperture. A Class II cabinet uses an airfoil to produce a vacuum and route air beneath the work surface rather than over it, which forms an air barrier at the front of the cabinet, which is the main distinction between Class I and Class II cabinets. To reduce turbulence and the chance of cross-contamination inside the cabinet, it filters the air supply to the internal work area and uses laminar airflow.

- Further distinctions between these cabinets’ types are made in light of their construction, ventilation, and exhaust systems. The proportion of air evacuated from the BSC to air recirculated inside the BSC and the kind of exhaust system used are the key distinctions between the types.

- A1, A2, B1, B2, and C1 are among the types.

- The three main features are:

- Product protection with downward HEPA-filtered unidirectional/laminar airflow

- Open front with careful regulated inward airflow for personnel protection

- HEPA-filtered exhaust air is directed toward a room or a facility exhaust system for environmental protection.

Class II Type A1 Biosafety Cabinet

Working mechanism of Class II Type A1 Biosafety Cabinet

With a face velocity of 0.38 m/s or 75 fpm, the inbound airflow enters the cabinet through the front entrance, which subsequently passes through a supply HEPA filter. After that, it proceeds downhill over the work surface.

It “splits” during the downward motion at a distance of 6 to 18 cm from the work surface, with half passing through the front exhaust grill and the other half via the rear exhaust grill. The created aerosols will be collected by this downward airflow and will travel via the front or rear exhaust grills, ensuring the highest level of product protection.

The air is let out into the area between the supply and exhaust filters at the top of the cabinet. Following that, the exhaust filter releases the remaining 30% of the air into the room’s atmosphere while the supply HEPA filter circulates 70% of the air inside the cabinet. This is because the two filters’ relative diameters dampen the adjustment of this ratio.

It is inapplicable to toxic chemicals and radioactive nucleotides.

Features of Class II Type A1 Biosafety Cabinet

- Front opening

- Sash

- Exhaust HEPA filter

- Rear plenum

- Supply HEPA filter

- Blower

Class II Type A2 Biosafety Cabinet

Working Mechanism of Class II Type A2 Biosafety Cabinet

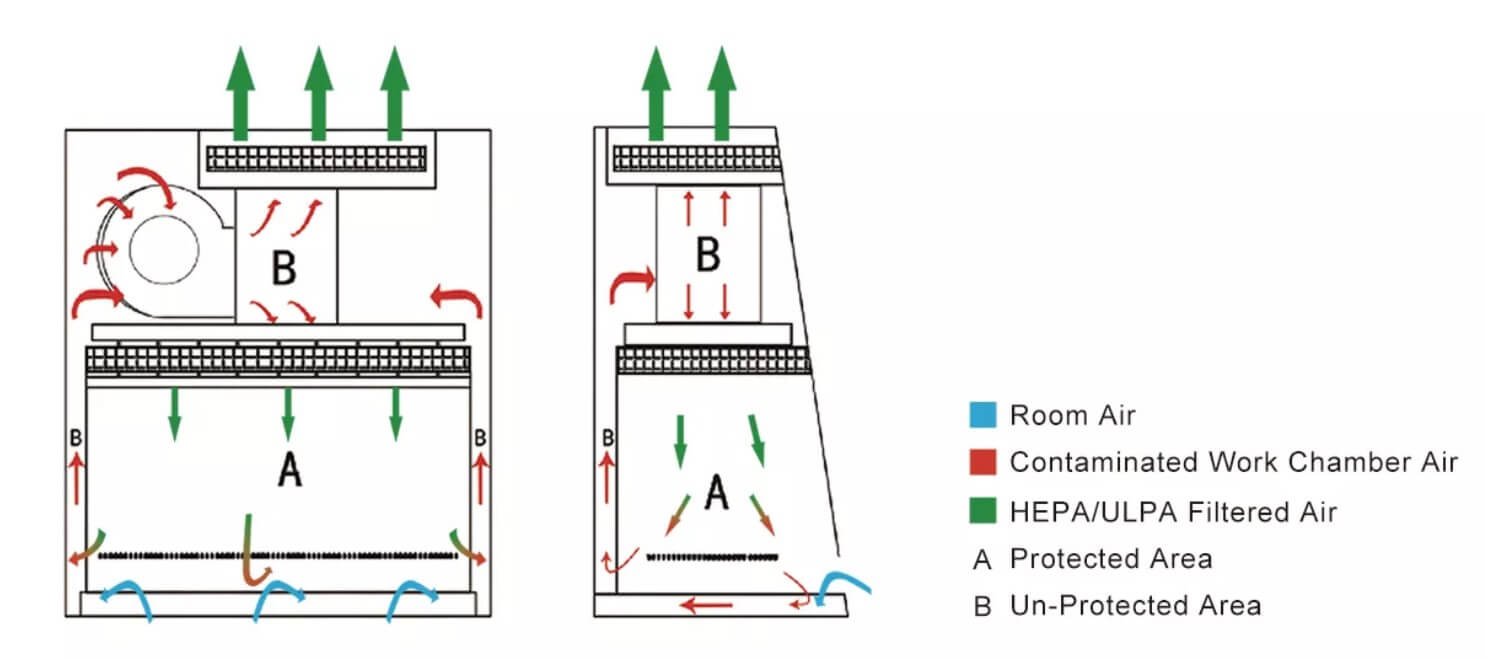

The front grill of the cabinet is used to draw in ambient air. A motor blower draws air through a plenum in the rear wall from underneath the work surface. Then, a small amount (30%) of the polluted air is expelled out of the top of the cabinet through a HEPA filter, entering the central plenum, where it is then forced into the central plenum. In a laminar (unidirectional) pattern, the residual air (70%) is cycled back into the work zone through a HEPA filter. The air divides on the work surface, is drawn through the front airflow grill, pulled back through the rear wall grill, and then dragged underneath the work surface to begin the air recirculation process. It also travels around the edges of the work surface and under its work surface.

Radio nucleotides and toxic chemicals are permitted for use in Type A2 Biosafety Cabinets.

Features of Class II Type A2 Biosafety Cabinet

- The front opening

- Sash

- Exhaust HEPA filter

- Supply HEPA filter

- Positive pressure plenum

- Negative pressure plenum

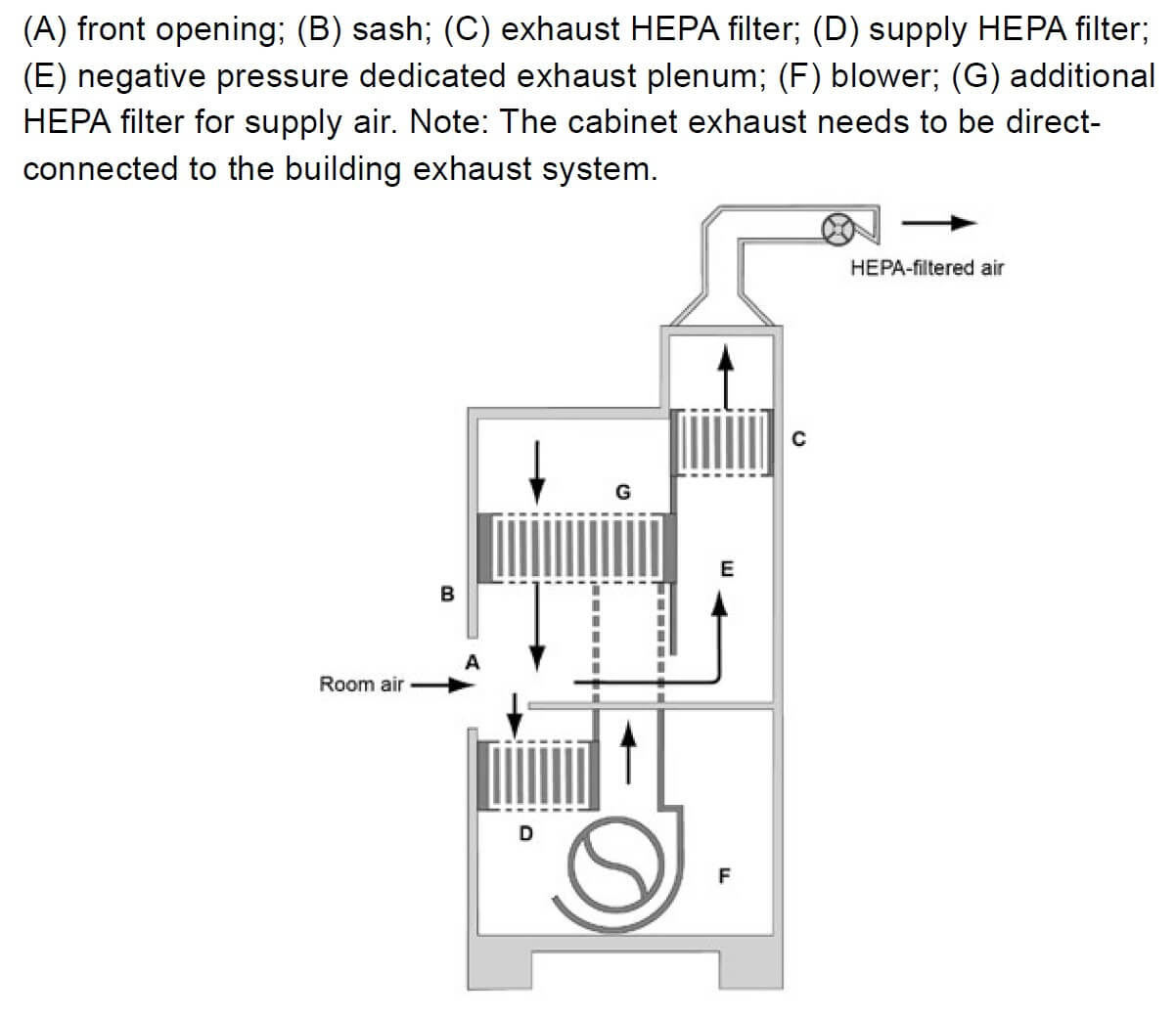

Class II Type B1 Biosafety Cabinet

Working mechanism of Class II Type B1 Biosafety Cabinet

The cabinet works are a hybrid of Type A2 and Type B2. Similar to Type A2, the inflow and the front portion of the downflow are drawn into the front airflow grill, where they are directed to a region under the work surface where they can flow back towards the back of the cabinet. The air then proceeds up a vertical path to the plenum. This plenum connects to the supply HEPA filter below it and directs air through that HEPA filter in a downward direction into the work area. The internal blower motor drives this air circuit, which accounts for around 30% of the air passing through the cabinet. An external exhaust blower that powers a second air circuit operates simultaneously. This external blower pulls the back part of the cabinet downflow into another airflow grill, i.e. second plenum at the back of the work zone. This plenum is connected to the exhaust HEPA filter through which that external exhaust blow now extracts 70% of the air.

Features of Class II Type B1 Biosafety Cabinet

- The front opening

- Sash

- Exhaust HEPA filter

- Supply plenum

- Supply HEPA filter

- Blower

- The negative pressure exhaust plenum

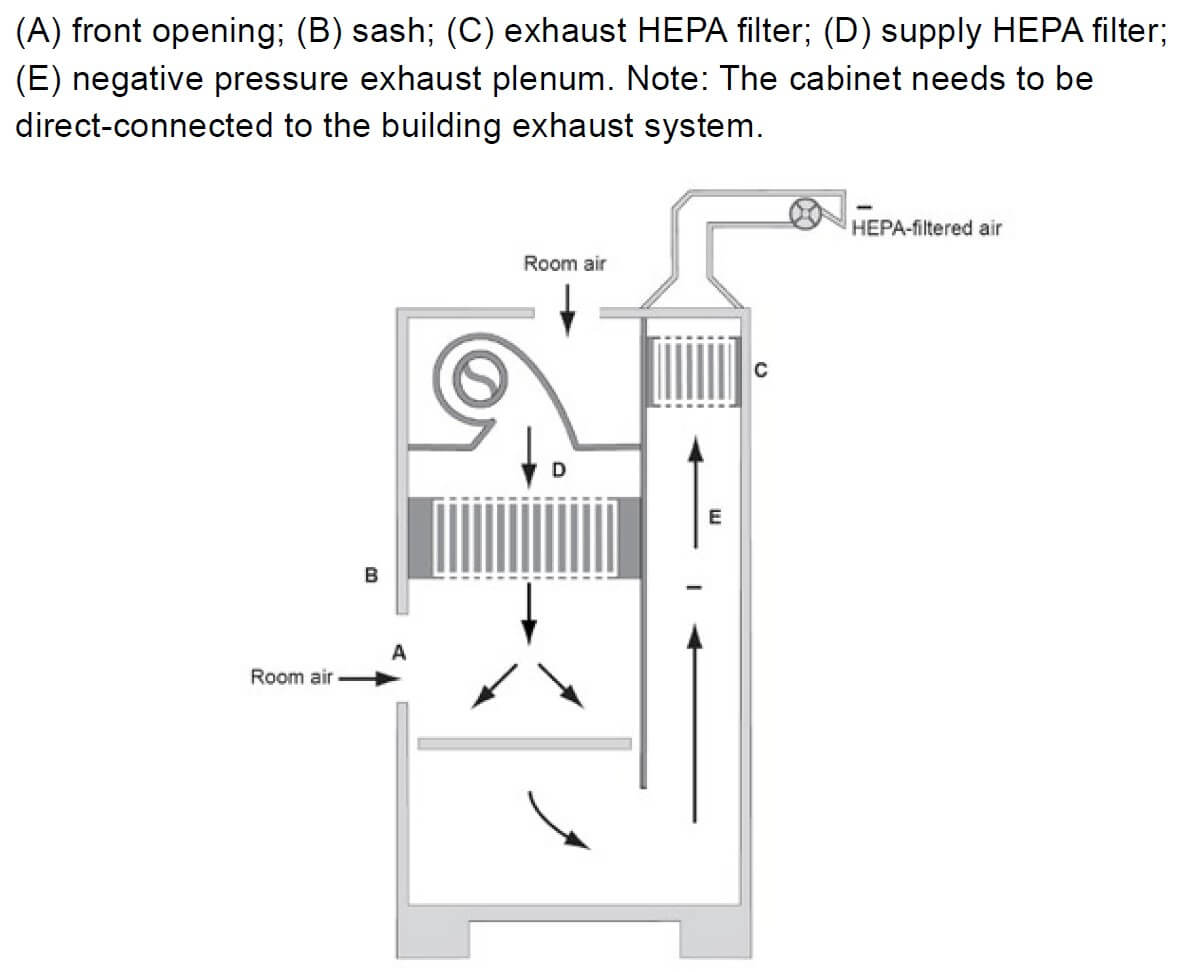

Class II Type B2 Biosafety Cabinet

Working mechanism of Class II Type B2 Biosafety Cabinet

The Type B2 cabinet features an internal motor that pushes air past the supply HEPA filter and into the work zone to produce downflow. The air is drawn into the room through an opening at the top of the cabinet. The air that the internal blower forces down into the work area combines with the air that is drawn into the front access aperture to form the air that is pulled out by the external exhaust blower during normal operation. The only function of the internal motor is to draw air into the opening. The Type B2 cabinet is unable to operate independently. It needs to be paired with an external exhaust blower that has enough force to both pull air into the front of the cabinet and to keep pulling exhaust air out of the cabinet, through the ductwork, and back into the cabinet. The internal blower must stop forcing air down into the work zone if the external exhaust blower ever fails and is no longer able to generate enough “pull” to keep air flowing in that direction toward the user. Hazardous particles could escape from that work zone and move toward the user. There is no recirculation with 100% air exhausted through HEPA filters.

These cabinets work best for operations that need the emission of chemical vapors because no air is recirculated in them.

Features of Class II Type B2 Biosafety Cabinet

- The front opening

- Sash

- Exhaust HEPA filter

- Supply plenum

- Supply HEPA filter

- Blower

- The negative pressure exhaust plenum

- Container Supply Blower

- Filter screen

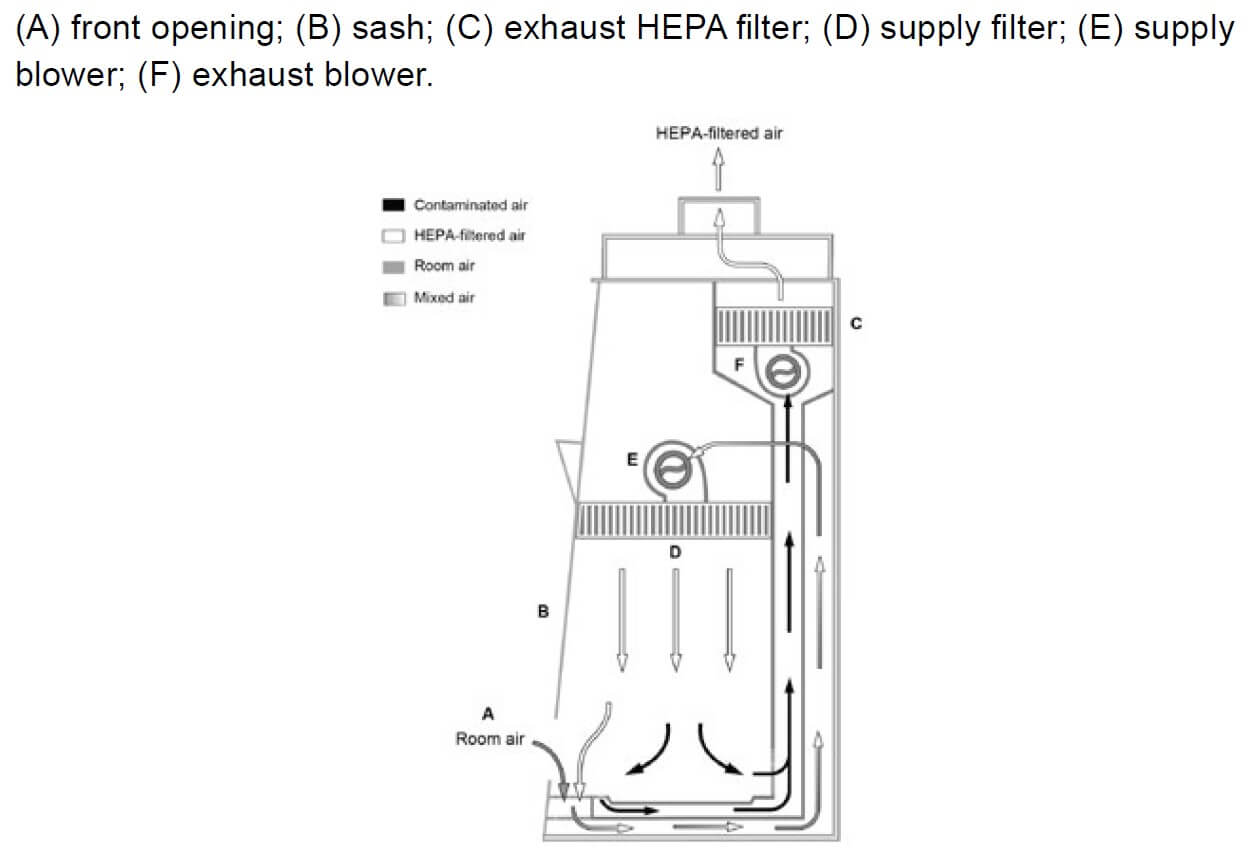

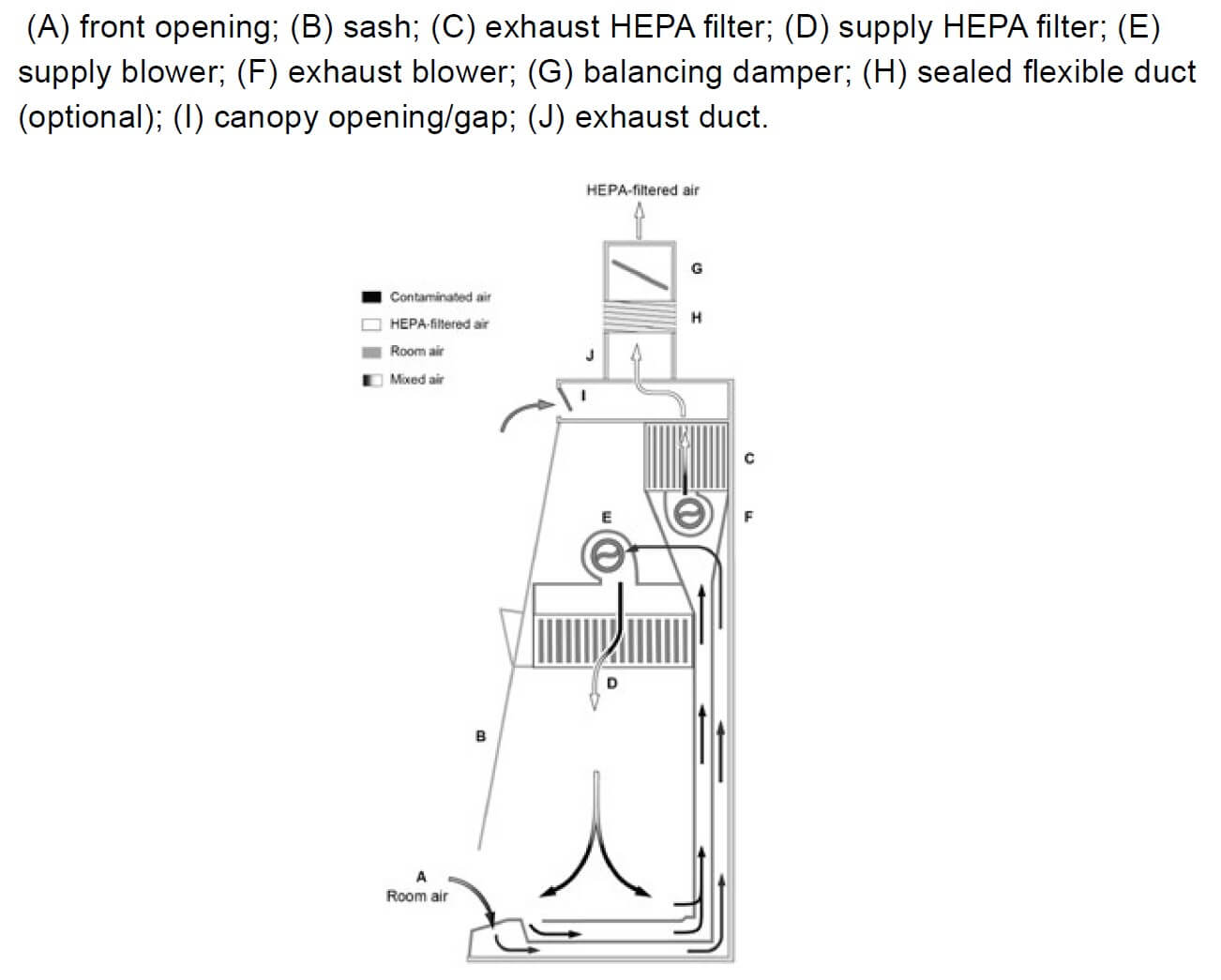

Class II Type C1 Biosafety Cabinet

- It is the first biological safety cabinet to keep an average inflow velocity via the sash aperture of at least 105 fpm.

- When in recirculating mode, they can function as type A cabinets, and when in exhausting mode, as type B cabinets.

- By connecting or removing the exhaust and having the cabinet recertified, C1 cabinets may change modes fast.

- It also has a designated direct exhaust work area for usage with radionuclides or hazardous vapors, as well as a demarcated work area with clearly defined storage areas.

Working mechanism (Not connected to building exhaust)

Through the front aperture, which is located under the sash, room air enters the Class II, Type C1 biosafety cabinet’s front. The air in the working area of the BSC is then divided, with some air going back to a supply blower and supply filter and the other air going via an exhaust blower and exhaust HEPA filter. Direct exhaust into the room uses HEPA filtration.

Working mechanism (Connected to building exhaust)

The front aperture, located beneath the sash, allows room air to enter the Class II, Type C1 biosafety cabinet. After that, the air in the BSC’s working area is divided, with some going back to a supply blower and supply filter and the others going via an exhaust blower and exhaust HEPA filter. Direct emission into the room is done using HEPA-filtered air. Without passing through the BSC, room air can enter the building exhaust ductwork through a canopy opening/gap at the upper front of the structure. The facility exhaust system is connected to the exhaust duct through optional flexible ducting.

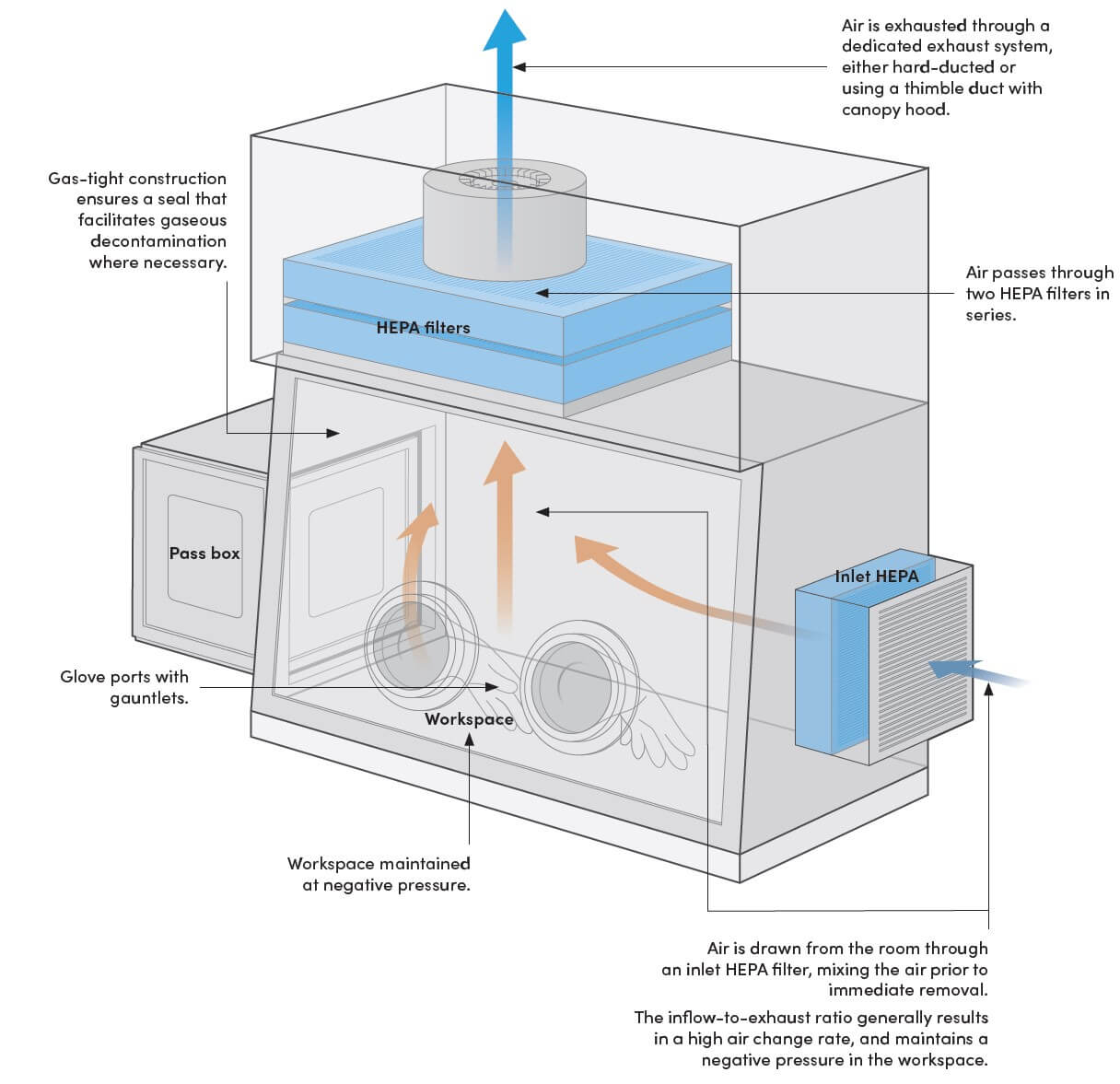

C. Class III Biosafety Cabinet

- It offers the highest level of security for people, products, and the environment.

- It is a completely sealed, non-opening enclosure that is aerosol-tight.

- The Class III Biosafety Cabinet is intended for use with BSL-4 pathogenic pathogens.

Working Mechanism of Class III Biosafety Cabinet

Under pressure, this type of cabinet is examined to ensure that no particles can escape and enter the space. HEPA filters are used to filter the supply air, and two HEPA filters are used to release the exhaust air into the atmosphere. These metal-welded gas-tight chambers have heavy-duty rubber glove apertures in the front cabinet used to operate the work. The work surface can be expanded by connecting several glove boxes. The cabinet’s interior is kept under negative pressure by a dedicated exhaust system located outside the cabinet. A double-door autoclave that decontaminates all materials entering or leaving the Class III cabinet may be attached to it. The Class III BSCs must have an associated pass-through box or dunk tank that can be sterilized and has an exhaust system with a HEPA filter.

Features of Class III Biosafety Cabinet

- Contain glove ports with an O-ring for attaching arm-length gloves to the cabinet.

- Sash

- Double Exhaust HEPA filters

- Supply HEPA filter

- Double-ended autoclave or pass-through box.

- Chemical dunk tank

Uses of Class III Biosafety Cabinet

- Weighing and dilution of chemicals that cause cancer.

- To investigate the risky agents

- To research emerging diseases.

- To research diseases that are almost completely eradicated

- To handle dangerous or highly contagious experimental materials

Biological Safety Cabinets Operating Procedures

- Prepare Work Area

- Switch off the UV light and on the fluorescent

- Switch on the blower and check the air grilles for blockages.

- Allow air to purge workspace 5-10 minutes

- Pre-disinfection

- Apply the appropriate disinfectant to all interior surfaces by spraying or wiping

- Allow air-dry

- Assembly of materials and equipment

- Only include the materials necessary to carry out the process.

- Set up the materials such that they don’t come into contact with any tainted ones.

- Position the container for hazardous materials at the right rear.

- Make sure the view screen is positioned correctly and fastened.

- Pre-purge cabinet

- When there is no activity inside, let the air purge.

- Self-preparation

- Wear protective clothing, gloves, mask, etc.

- Do the procedures

- Once operations are finished, and all necessary materials are secured, do not remove your hands from the work area. Remove your gloves before handling any contaminated materials.

- Post-purge cabinet

- When there is no activity inside, let the air purge.

- Finish personally

- Take off your protective clothing, and mask, and wash your hands

- Post-disinfection

- Remove gloves and materials, place them in a biohazard bag, put them in an autoclave if necessary, and disinfect all internal surfaces with the proper cleaner.

- Shut down cabinet

- Turn off the fan and the fluorescent light, then on the UV lamp.

Applications of Biological Safety Cabinets

- Opening containers with non-ambient pressures

- Intranasal inoculation of animals

- Harvesting infected tissues/fluids or embryonated eggs

- Necropsy of infected animals

- Transfer operations

- Specimen separation

- Sonication

- Blending and Grinding

- Aliquoting

- Vortex-mixing

- Centrifugation

- Use of pipettes and other laboratory activities

However, it is not necessary to operate aerosol containment equipment in a BSC as long as the containers (such as rotors or centrifuge safety cups) are only opened in a BSC.

Advantages of Biological Safety Cabinets

- It shields the user from any infectious agents present inside the cabinet.

- It guards against contamination of the sample.

- It offers defense against contaminants inside the cabinet for the laboratory environment.

- It removes significant amounts of smoke and heat.

- It permits research on pathogens with low and moderate risk.

- BSC class III is appropriate for pathogens with moderate to high risks.

Limitations of Biological Safety Cabinets

- The front aperture opening of BSC classes I and II increase the risk of exposure to hazardous substances.

- Contamination can be caused by airflow disruption.

- It’s costly and requires skilled professionals to operate.

Precautions

- Put on the Personal Protective Equipment (PPE) such as a lab coat, gloves, and safety glasses.

- If at all feasible, place the materials in the cabinet before starting the work.

- When working in the cabinet, never turn on the UV light. In addition to skin burns, it can harm the eyes.

- Never use Bunsen burners, other continuous flame appliances, or other dangerous gases in biosafety cabinets.

- Refrain from interfering with airflow.

- Reduce mobility, especially quick movements, into and out of the BSC and in the vicinity of the BSC.

- Do not use your arms or objects to block the front grill or the back vents.

- Work at least 4 inches from the front vent’s inside edge.

Examples of Biological Safety Cabinets

a. Class I Biological safety cabinet BBS, BYKG series (Manufacturer: Biobase)

Features

- Positive pressure solely protects the sample in the work area of the vertical laminar flow cabinet from the BBS series.

- Negative pressure in the work area and a Class I biological safety cabinet from the BYKG series safeguard the environment and the operator.

- Variable air speed

- Easy to transport and space-saving tabletop style.

- LED display and microprocessor control system.

- HEPA filter with a 99.999% efficiency at 0.3 μm.

b. Biological Safety Cabinet, BSC-IIA2-2J (Manufacturer: Bioevopeak)

Features

- High-Quality and Ergonomic Design

- Extreme security

- Front window design that is useful and convenient

c. Class II Biological safety cabinet IF-MVK 183 (Manufacturer: UNO)

Features

- The work opening in UNO Microbiological Safety Cabinets enables the user to carry out tasks in the workspace.

- The user is safeguarded by design, which minimizes the risk of product- and cross-contamination.

- The internal airflow in the cabinet and the filtering of the exhaust air also minimize the escape of airborne particles.

d. Class III Biological safety cabinet BMB-III- “Laminar-S”-1,2 PROTECT VIS-À-VIS (Manufacturer: LAMSYSTEMS)

Features

- The cabinet is made for operators to operate cross-legged at the same time.

- The cabinet might be utilized for protection from radionuclides and small amounts of harmful chemicals if it was connected to each person’s active exhaust system.

- The operator is alerted by the monitoring system’s audio-visual indication system when a cabinet’s functioning modes fail.

References

- https://aip.scitation.org/doi/full/10.1063/5.0047716

- https://labsafety.gwu.edu/biosafety-cabinets

- https://ehs.mit.edu/biological-program/biological-biosafety-cabinets/

- https://www.labogene.com/Biological-Safety-Cabinets

- https://www.laboratory-supply.net/blog/aseptic-containment-isolator-vs-biological-safety-cabinet/

- https://blink.ucsd.edu/safety/research-lab/biosafety/containment/bsc/usage.html#Take-precautions-before-beginni

- https://microbeonline.com/biological-safety-cabinet-bsc-types-working-mechanism/

- https://www.labconco.com/articles/what-are-the-biosafety-cabinet-classes

- https://www.nuaire.com/resources/biosafety-cabinet-classes-article

- https://www.slideshare.net/RaviKantAgrawal/biosafety-levels-biological-safety-cabinets-and-biosafety-laboratory-construction

- https://www.who.int/publications/i/item/9789240011335

- https://www.medicalexpo.com/prod/lamsystems/product-106773-947424.html

- https://www.medicalexpo.com/prod/biobase/product-84845-651613.html

- https://bioevopeak.com/products/biological-safety-cabinet-bsc-iia2-2j/

- https://www.medicalexpo.com/prod/uno/product-125095-900267.html

Thank you! it’s really interesting. Good job!