Plastics have become an essential part of modern society. Many of the products we use in our daily lives are made of plastics. Plastics are crucial in various industries like transportation, food, healthcare, and energy.

However, population growth and increasing demand for goods have led to a substantial increase in plastic production, leading to the generation of massive quantities of plastic waste and environmental concerns, including the emission of greenhouse gases (GHGs). Only around 9% of the plastic waste produced is recycled, causing the remaining untreated plastic waste to accumulate in our lands and oceans. This accumulation is causing severe harm to the environment, plants, and animals, as well as posing risks to human health.

In order to address these challenges, it is necessary to explore and implement alternative, sustainable methods where non-renewable resource use is minimized and materials are reused and recycled. One promising approach involves using biomass as renewable raw materials. This type of plastic is known as bioplastic.

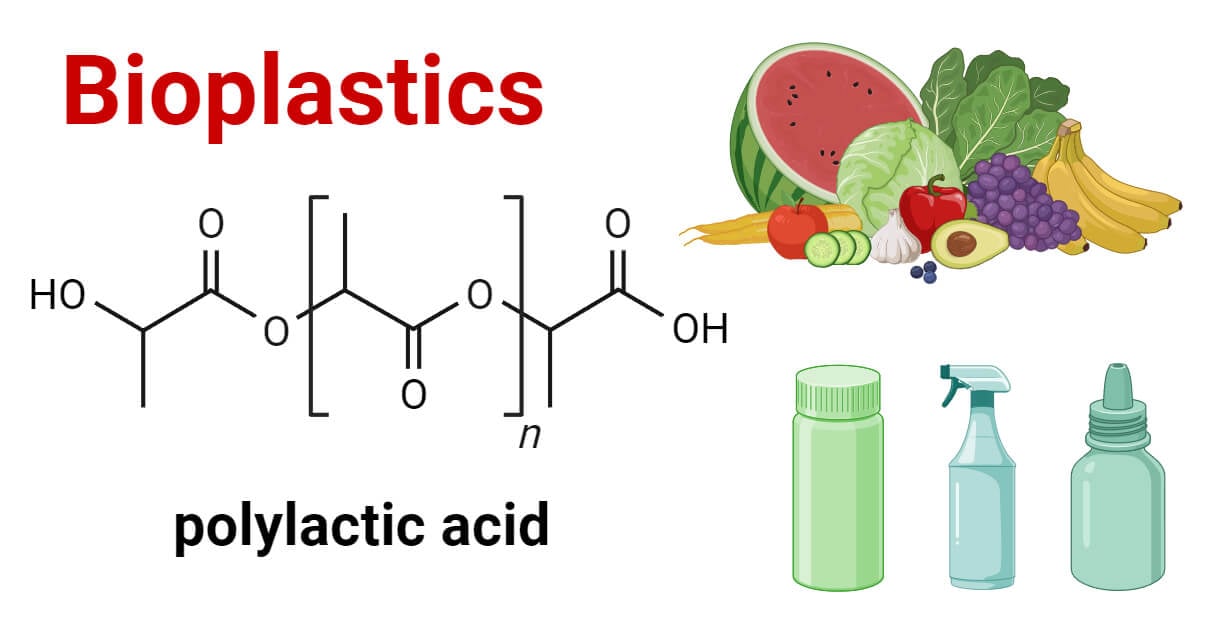

Bioplastics are alternatives to fossil-based conventional plastics that are made from renewable sources like plant biomass. They are often 100% bio-based and are considered sustainable as they reduce reliance on fossil resources, introduce eco-friendly disposal options, and use less toxic production methods.

Interesting Science Videos

What are Bioplastics?

Bioplastics are sustainable alternatives to traditional plastics made from renewable sources, are biodegradable, or are manufactured through biological processes.

- Simply, bioplastics refer to plastics derived from plant or biological sources.

- According to European Bioplastics, bioplastic is defined as having one or both of these traits: it’s either biobased or biodegradable.

- Being biobased means that the main source of the product is biomass, primarily plants such as corn and sugarcane.

- Biodegradation is a process where microorganisms in the environment convert the products into natural substances, such as water, carbon dioxide, and compost.

- It’s important to understand that “biobased” and “biodegradable” are not the same. The biodegradability is related to the chemical structure of the material, not the source of the product. This means that bioplastics can be entirely biobased and still not biodegrade, while some fossil-based plastics are biodegradable.

- Some biodegradable plastics, despite being derived from fossil fuels, are also sometimes labelled as bioplastics which is discouraged to avoid confusion in the definition of bioplastics.

Types of Bioplastics

The two major types of bioplastics produced in large quantities are polylactic acid (PLA) and polyhydroxyalkanoate (PHA). Besides these, there are several other bioplastics such as cellulose-based, starch-based, and protein-based polymers.

- PLA is derived from sugars found in crops like corn, cassava, or sugarcane. Its basic building blocks are lactides or lactic acid monomers, which are polymerized to create PLA. PLA has numerous advantageous characteristics, including ease of fabrication, biodegradability, and non-toxicity. When PLA undergoes biodegradation, it releases CO2, water, and decomposed organic matter, which can be used by green plants. PLA is commonly used in green packaging for fresh food products and also has applications in sectors such as construction, agriculture, transportation, electronics, household goods, and textiles.

- PHA is a thermoplastic polyester created from the polymerization of (R)-3-hydroxyalkanoic acid monomers. PHA is made by microorganisms. These microbes synthesize PHA as a means of storing energy and carbon intracellularly. PHA has a wide range of applications, particularly in biodegradable implants, drug delivery systems, tissue engineering, and anticancer and antibacterial treatments. PHA is biodegradable and harmless to living tissues so it is commonly used in medical applications. It also has applications in single-use food packaging.

Conventional Plastics vs. Bioplastics

| Conventional Plastics | Bioplastics | |

| Source | Derived from fossil fuels and petroleum-based sources | Produced from natural, renewable resources |

| Resource Availability | Reliant on finite fossil fuel resources | Utilize renewable resources |

| Biodegradability | Most conventional plastics are non-biodegradable | Many bioplastics are biodegradable |

| Environmental Impact | Contributes to environmental pollution | Often considered more environmentally friendly |

| Common Applications | Used in packaging, bags, bottles, construction, textiles, electronics, and more | Applied in biodegradable food packaging, automotive parts, biomedical tools, and more |

| Examples of Materials | Polyethylene terephthalate, polyvinyl chloride, polystyrene | Polyhydroxyalkanoate, polylactic acid, polyhydroxyurethanes |

Benefits of Bioplastics

- Bioplastics contribute to a cleaner environment by lowering greenhouse gas emissions.

- Manufacturing bioplastics typically requires less energy than traditional plastics, promoting energy efficiency.

- Bioplastics reduce the dependence on non-renewable fossil fuels and contribute to carbon neutrality by using renewable biomass resources.

- Biodegradable bioplastics provide an eco-friendly end-of-life solution, reducing landfill waste and environmental pollution.

- Bioplastics do not contain harmful additives like phthalates or bisphenol A.

- Bioplastics are versatile and suitable for various applications, from packaging to medical devices, offering a wide range of sustainable solutions.

Challenges and Limitations of Bioplastics

While bioplastics are eco-friendly alternatives, they do have their limitations. Despite their potential benefits, the widespread use of bioplastics faces numerous challenges.

- Production of bioplastic requires extensive land resources for cultivating the plants for raw materials, which adds pressure on both the environment and the food supply.

- Similar to conventional plastics, bioplastics also raise concerns about chemical leaching.

- The effectiveness of bioplastics depends on factors such as their chemical composition, manufacturing processes, and end-of-life management.

- The use of bioplastics has hidden environmental costs, such as the use of toxic pesticides on crops and carbon dioxide emissions from harvesting equipment.

- Many bioplastic manufacturing facilities rely on fossil fuels to power their operations, consuming nearly as much energy as conventional plastic production.

- The utilization of edible biomass raises ethical concerns regarding potential competition with food production. More efficient methods for using biowastes must be developed.

Bioplastics Future Perspectives

Bioplastics are continually evolving. Researchers are actively working on developing the next generation of bioplastics. Ongoing research focuses on developing factors such as recycling methods, cost, durability, and biodegradation.

The Circe project is one innovation in bioplastic that uses engineered microbes to produce biodegradable plastics. Unlike traditional bioplastics made from crops, Circe’s microbes feed on carbon dioxide and hydrogen gases to create eco-friendly polymers suitable for various products, from packaging materials to cosmetics. Shrilk is another innovation that derives its base materials from shrimp shells (chitosan) and silk protein (fibroin). These innovations represent promising steps toward more sustainable bioplastics.

Future bioplastics will resemble traditional plastics but with reduced environmental impact. In the future, the industry plans to transition from edible first-generation biomass to non-food crops. More efficient methods for using second-generation biowastes must be developed. While advancements are underway, individuals can also contribute by reducing disposable plastic use.

References

- Bioplastics – European Bioplastics e.V. (european-bioplastics.org)

- Bioplastics (harvard.edu)

- Cho, R. (2017, December 13). The Truth About Bioplastics. State of the Planet. https://news.climate.columbia.edu/2017/12/13/the-truth-about-bioplastics/

- Gibbens, S. (2018, November 15). What you need to know about plant-based plastics. National Geographic. https://www.nationalgeographic.com/environment/article/are-bioplastics-made-from-plants-better-for-environment-ocean-plastic

- Nanda, S., Patra, B. R., Patel, R., Bakos, J., & Dalai, A. K. (2022). Innovations in applications and prospects of bioplastics and biopolymers: A review. Environmental Chemistry Letters, 20(1), 379-395. https://doi.org/10.1007/s10311-021-01334-4

- Rosenboom, J., Langer, R., & Traverso, G. (2022). Bioplastics for a circular economy. Nature Reviews Materials, 7(2), 117-137. https://doi.org/10.1038/s41578-021-00407-8

- Washam, C. (2010). Plastics Go Green. ChemMatters. chemmatters-april2010-bioplastics.pdf (acs.org)

- What are bioplastics? (activesustainability.com)